High-strength Piping For High-pressure Industrial Systems

Seamless pipes and tubes for pressure applications offer high strength and corrosion resistance for demanding industries like oil, gas, and power generation.

High-strength Piping For High-pressure Industrial Systems

Seamless pipes and tubes for pressure applications offer high strength and corrosion resistance for demanding industries like oil, gas, and power generation.

Specifications of

Seamless steel pipes and tubes are engineered to strict ASTM standards, ensuring durability and performance under high pressures and temperatures in diverse applications.

Manufactured without seams, these pipes meet specifications like ASTM A106 for high-temperature service and ASTM A333 for low-temperature applications, ideal for boilers, heat exchangers, and general service.

Key standards include ASTM A335 for ferritic alloy-steel pipes, ASTM A209 for carbon-molybdenum boiler tubes, and ASTM A213 for ferritic/austenitic alloy-steel tubes, ensuring reliability in demanding conditions.

Seamless Pipes and Tubes for Pressure Applications are engineered to withstand extreme pressure and temperature conditions, making them ideal for critical industries such as oil and gas, power generation, and chemical processing. These high-pressure seamless tubes comply with standards like ASTM A106, ASTM A335, and EN 10216, ensuring superior strength, durability, and corrosion resistance for demanding applications like boilers, heat exchangers, and pipelines.

Manufactured from high-quality materials such as carbon steel (e.g., A106 Grade B), alloy steel (e.g., P11, P22), or stainless steel (e.g., 316L), carbon steel pressure pipes are produced through hot-rolling or cold-drawing processes to achieve precise dimensions and a smooth finish. Available in sizes from 1/8” to 24” (DN6–DN600) with wall thicknesses from SCH 40 to SCH XXS, these pipes are designed to handle pressures up to 250 bar and temperatures up to 600°C, making them suitable for high-pressure steam, gas, and fluid transport.

Alloy steel pressure tubes undergo rigorous testing, including hydrostatic, tensile, and non-destructive tests (e.g., ultrasonic, eddy current), to ensure defect-free performance. With tensile strengths ranging from 415 MPa (A106 Grade B) to 655 MPa (P22), these pipes resist creep, thermal fatigue, and corrosion, ensuring reliability in harsh environments. Surface treatments like 3LPE, FBE, or galvanizing enhance corrosion resistance, making them ideal for transporting corrosive fluids or operating in coastal or acidic conditions.

Compared to welded pipes, seamless piping for high pressure offers superior integrity due to the absence of weld seams, reducing the risk of leaks or failures under high pressure. Their uniform structure ensures consistent performance in applications like refineries, petrochemical plants, and power boilers. These pipes can be customized with specific grades, sizes, and coatings to meet project requirements, providing flexibility for complex piping systems.

By addressing challenges like high-pressure demands, corrosion, and thermal stress, corrosion-resistant pressure pipes deliver unmatched safety and longevity. Whether used in oil pipelines, steam boilers, or chemical reactors, these seamless pipes ensure efficient and reliable operation, making them essential for high-pressure industrial applications.

Our Tubes and Pipes for Pressure Applications ensure safety and efficiency in refineries, power plants and the chemical and petrochemical industries. They are ideal for heat exchangers, waste heat recovery and industrial high-pressure systems.

Seamless pipes support hydrocarbon processing, catalytic cracking units, hydrodesulfurization reactors, and downstream media extraction—providing unmatched resistance in high‑temperature and high‑pressure environments.

Used in high‑pressure boiler tubes, superheaters, reheaters, economizers, and steam lines—capable of withstanding pressures up to ~300 bar and temperatures up to 600 °C for efficient heat transfer.

Seamless piping systems are essential for high-pressure reactors and waste heat recovery units—handling corrosive media and temperature cycling with strong material integrity.

Ideal for industrial equipment requiring uniform wall thickness and reliability, including hydraulic systems, pressure vessels, and specialized high‑pressure process lines.

Employed in waste heat recovery units and economizers—seamless tubes facilitate highly efficient thermal exchange in power generation and process industries.

High‑pressure carbon or alloy steel fittings including forged elbows, tees, reducers, adapters, and olets are essential for junctions in process piping—available in welded or seamless forms as required.

Explore the dimensional ranges and common applications of various seamless pipe types.

| Type | Outer Diameter | Wall Thickness | Length | Applications |

|---|---|---|---|---|

| Hot-Rolled Seamless | Above 32 mm | 2.5 – 200 mm | Up to 12 m | General industrial, structural |

| Cold-Rolled Seamless | 6 – 650 mm | 0.25 – 50 mm | Up to 12 m | Precision applications |

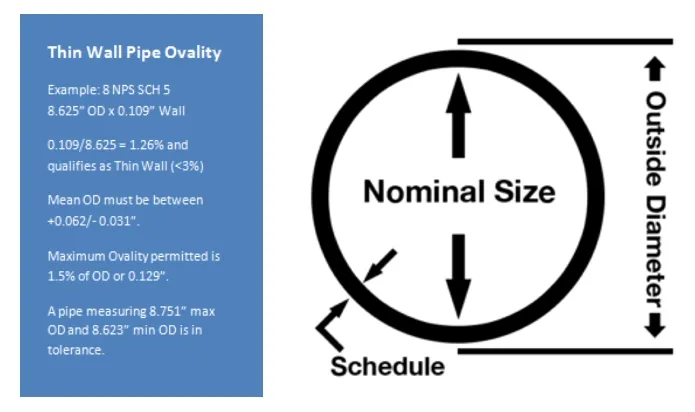

| Thin-Walled Pipe | 5 – 100 mm | Less than 0.25 mm | Up to 6 m | Instrumentation, automotive |

| Heavy Wall Pipe | 50 – 650 mm | 10 – 200 mm | Up to 12 m | High pressure, structural |

| DN | NB (inch) | OD (mm) | Nominal Wall Thickness (mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS | |||

| 15 | 1/2" | 21.3 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |||||

| 20 | 3/4" | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |||||

| 25 | 1" | 33.4 | 2.77 | 2.90 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |||||

| 32 | 1.1/4" | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | |||||

| 40 | 1.1/2" | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | |||||

| 50 | 2" | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |||||

| 65 | 2.1/2" | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |||||

| 80 | 3" | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.25 | |||||

| 90 | 3.1/2" | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | |||||||

| 100 | 4" | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 | |||||

| 125 | 5" | 141.3 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | |||||

| 150 | 6" | 168.3 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8" | 219.1 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10" | 273 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 12" | 323.8 | 4.57 | 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 14" | 355.6 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16" | 406.4 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.19 | |

| 450 | 18" | 457.2 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.7 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20" | 508 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | |

| 550 | 22" | 558.8 | 6.35 | 9.53 | 12.7 | 9.53 | 22.23 | 12.7 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24" | 609.6 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.7 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26" | 660.4 | 7.92 | 12.7 | 9.53 | 12.7 | |||||||||

| 700 | 28" | 711.2 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 750 | 30" | 762 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 800 | 32" | 812.8 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 850 | 34" | 863.6 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 900 | 36" | 914.4 | 7.92 | 12.7 | 15.88 | 9.53 | 19.05 | 12.7 | |||||||

Seamless Pipes

Seamless pipes, available in various wall thicknesses, are designed for precise applications, with cold-rolled thin-walled pipes achieving thicknesses as low as 0.25 mm or less.

The outer diameter of hot-rolled seamless pipe is generally greater than 32mm, the wall thickness is 2.5-200mm, the outer diameter of cold-rolled seamless steel pipe can be 6mm, the wall thickness can be 0.25mm, the outer diameter of thin-walled pipe can be 5mm, and the wall thickness is less than 0.25mm, cold rolling

The ability to produce seamless pipes with ultra-thin walls and controlled ovality makes them critical for industries like automotive, hydraulics, and petrochemicals, ensuring reliability and performance.

| NPS/ DN/ OD | Permissible Variations in Outside Diameter | |||

|---|---|---|---|---|

| Over | Under | |||

| in. | mm | in. | mm | |

| NPS 1/8 to 1½, incl DN 6 to 40 OD 10.3 to 48.3, mm |

1/64 | 0.4 | 1/64 | 0.4 |

| Over 1½ to 4, incl DN 40 to 100 OD 48.3 to 114.3, mm |

1/32 | 0.8 | 1/32 | 0.8 |

| Over 4 to 8, incl DN 100 to 200 OD 114.3 to 219.1, mm |

1/16 | 1.6 | 1/32 | 0.8 |

| Over 8 to 18, incl DN 200 to 450 OD 219.1 to 457, mm |

3/32 | 2.4 | 1/32 | 0.8 |

| Over 18 to 26, incl DN 450 to 650 OD 457 to 660, mm |

1/8 | 3.2 | 1/32 | 0.8 |

According to the production method, seamless tubes are divided into hot - rolled tubes, cold - rolled tubes, cold - drawn tubes, extruded tubes, jacking tubes, etc. The maximum diameter is 650 mm and the minimum diameter is 0.3 mm. Depending on the application, there are thick - walled tubes and thin - walled tubes. Seamless steel tubes are mainly used as petroleum geological drilling tubes, cracking tubes for petrochemical industry, boiler tubes, bearing tubes and high - precision structural steel tubes for automobiles, tractors and aviation. In the plate, Q345B seamless steel pipe belongs to the low - alloy series.

Among the low - alloy materials, this kind of material is the most common. The outside diameter of hot - rolled seamless pipe is usually more than 32mm, the wall thickness is 2.5 - 200mm, the outside diameter of cold - rolled seamless steel pipe can be 6mm, the wall thickness can be 0.25mm, the outside diameter of thin - walled pipe can be 5mm, and the wall thickness is less than 0.25mm, cold rolling has higher dimensional accuracy than hot rolling.

A consolidated overview of international seamless pipe standards, their materials, and applications.

| Standard System | Standard Code | Material Type | Typical Applications |

|---|---|---|---|

| ASTM / ASME (USA) |

ASTM A53 | Carbon Steel | General-purpose piping, structural |

| ASTM A106 | Carbon Steel | High-temperature service | |

| ASTM A179 | Low Carbon Steel | Heat exchangers, condensers | |

| ASTM A333 | Carbon/Alloy Steel | Low-temperature service | |

| ASTM A335 | Alloy Steel | High-temperature, pressure piping | |

| ASTM A213 / A209 | Alloy/Stainless Steel | Boilers, superheaters | |

| ASTM A312 | Stainless Steel | Corrosion-resistant piping | |

| ASTM A519 | Carbon/Alloy Steel | Mechanical tubing (e.g., SAE 1026) | |

| ASTM A790 | Duplex Stainless Steel | High-strength, corrosion-resistant service | |

| API (Oil & Gas) |

API 5L | Carbon Steel | Oil & gas pipelines |

| API 5CT | Carbon Steel | Casing & tubing for wells | |

| JIS (Japan) |

JIS G3454/G3455/G3456 | Carbon Steel | Pressure piping service |

| JIS G3460 | Carbon Steel | Boilers, heat exchangers | |

| JIS G3429 | High-strength Steel | High-pressure gas cylinders | |

| GB (China) |

GB 3087 | Carbon Steel | Low & medium pressure boilers |

| GB 5310 | Carbon Steel | High-pressure boiler pipes | |

| GB/T 8163 | Carbon Steel | Fluid and structural use |

Seamless pipes are critical in various industries thanks to their excellent strength, temperature resistance, and structural uniformity. They ensure safe and efficient performance in demanding environments.

Used in steam pipelines, boiler tubes, superheaters, and heat exchangers for high-temperature and high-pressure conditions in power plants.

Transports crude oil, natural gas, and petroleum products in pipelines and refinery units, handling high-pressure and corrosion.

Handles chemicals, gases, and hazardous substances in reactors and heat exchangers, ensuring safe processing.

Applied in automotive systems and machinery for fluid conveyance and precision components requiring strength and accuracy.

Used in structural support, water and sewage systems, and building frameworks for strength and corrosion resistance.

Utilized in hydraulic and engine systems onboard, resisting corrosion in marine environments.

Employed in aircraft and military equipment for hydraulic systems and structural components.

Stainless pipes for hygienic transport of food and pharmaceutical products, maintaining sterility.

Designed for transporting slurries and chemicals in mining, withstanding abrasion and harsh conditions.

Other structural pipes provide high strength and v...

Steel pipe for gas cylinder offers high-strength, ...

Seamless pipes for high-temperature applications o...