High-strength Seamless Steel Tubes For Drilling Operations

Seamless drill pipe offers high-strength, corrosion-resistant solutions for oil, gas, and geothermal drilling, meeting api 5dp standards.

High-strength Seamless Steel Tubes For Drilling Operations

Seamless drill pipe offers high-strength, corrosion-resistant solutions for oil, gas, and geothermal drilling, meeting api 5dp standards.

Seamless Drill Pipe is a high-strength, seamless steel tube designed for oil, gas, and geothermal drilling, providing exceptional durability and torque transmission. Compliant with API 5DP and API SPEC 7-1 standards, these oil and gas drill pipes are engineered to withstand high pressure, torque, and corrosive environments, ensuring reliable performance in challenging drilling conditions.

Manufactured from high-strength, low-alloy steel (HSLA) grades such as E75, X95, G105, and S135, API 5DP drill pipes are produced through hot-rolling or cold-drawing processes, followed by friction welding to attach tool joints. Available in sizes from 2-3/8" to 6-5/8" outer diameter (OD) and lengths of Range 1 (18–22 ft), Range 2 (27–30 ft), or Range 3 (38–45 ft), these pipes feature threaded connections like NC26, NC38, or 5-1/2FH for secure assembly. The seamless design eliminates weld seams, ensuring uniform strength and resistance to axial tension and internal pressure.

High-strength drill pipes undergo rigorous testing, including ultrasonic, tensile, and impact tests, to ensure defect-free material and compliance with API standards. With tensile strengths ranging from 517 MPa (E75) to 931 MPa (S135), these pipes resist fatigue and wear in high-torque drilling. Surface treatments like phosphating or anti-corrosion coatings enhance corrosion-resistant drill pipe performance in harsh environments, such as wells containing hydrogen sulfide (H₂S) or carbon dioxide (CO₂). The hollow design facilitates drilling fluid circulation, cooling the drill bit and removing cuttings.

Compared to welded pipes, seamless drill pipes offer superior structural integrity and pressure resistance, making them ideal for deep well drilling and high-pressure applications. Their smooth inner surface reduces fluid friction, optimizing drilling efficiency. Customizable options, such as wear belts or double-shoulder connections, improve durability and torque capacity, addressing challenges like well deviation and material fatigue in complex geological conditions.

Geothermal drill pipes are designed to handle extreme temperatures (up to 300°C) and corrosive fluids, ensuring reliability in geothermal drilling. From onshore oilfields to offshore platforms, these pipes provide safe, efficient, and cost-effective solutions for resource extraction, meeting the demands of modern drilling operations.

Drilling Equipment

Thin wall drill pipes, ranging from 2 3/8” to 6 5/8” in diameter and 18 to 45 ft in length, ensure reliable power transfer in drilling operations, with quality control focused on friction welding welds.

Designed for drill strings with components like drill collars and stabilizers, these pipes feature threaded ends to connect rigs and milling equipment, withstanding external pressure, twisting, and heavy vibration in lengths of 18–22 ft (Range 1), 27–30 ft (Range 2), or 38–45 ft (Range 3).

Quality control emphasizes the friction welding weld and heat-affected zone, where microstructure determines mechanical properties, requiring precise analysis to ensure durability and performance under demanding conditions.

Features of

Drill pipe joints are engineered with advanced features like enhanced torsional strength and optimized designs to ensure durability, efficiency, and performance in demanding drilling operations.

Torsional Strength and streamlined optimization boost joint rigidity and reduce cyclic pressure loss, improving fishing ability and hydraulic performance for reliable drilling.

Smooth inner diameter minimizes turbulence and erosion, while the double shoulder design enhances stress distribution, fatigue resistance, and service life compared to API connections.

Drill Pipe

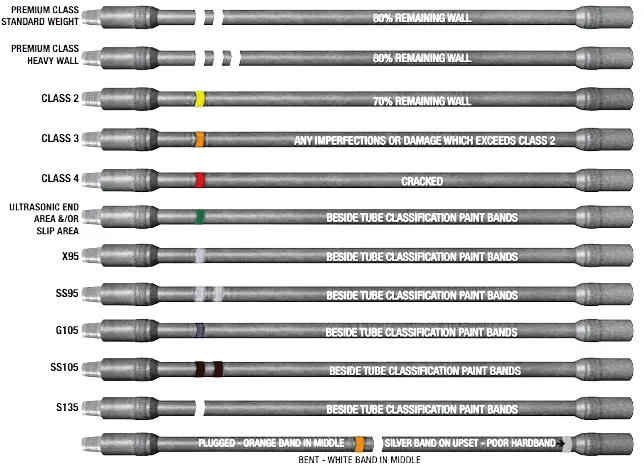

Drill pipes are classified by upset types and feature specialized thread connections to ensure strength, fluid flow, and compatibility in demanding drilling operations.

Upset Types: Internal Upset (IU) reduces inner diameter for slim-hole designs, External Upset (EU) maintains inner diameter for minimal pressure loss, and Internal-External Upset (IEU) enhances joint strength for high-stress applications.

Thread/Connection Types: NC26, NC31, NC38, NC40, NC46, NC50, 5-1/2 FH, and 6-5/8 FH ensure robust connections, while XT connections (X57, X75, X39, X95) enable larger pipes, like 5⅞” with XT57 in 8½” holes, for improved performance.

Drill Pipe Corrosion

Drill pipe corrosion, a critical issue in high-pressure, high-temperature drilling, is influenced by well conditions and can be studied using a novel method simulating reservoir-like environments.

Corrosion rates increase with higher temperature, pressure, and fluid speed but decrease with increased salinity in water-based drilling fluids, with negligible erosive effects from the fluid itself (excluding cuttings).

A proposed simulation method tests corrosion under static and dynamic conditions, replicating complex downhole environments to improve understanding and mitigation of drill pipe degradation.

Drilling Equipment

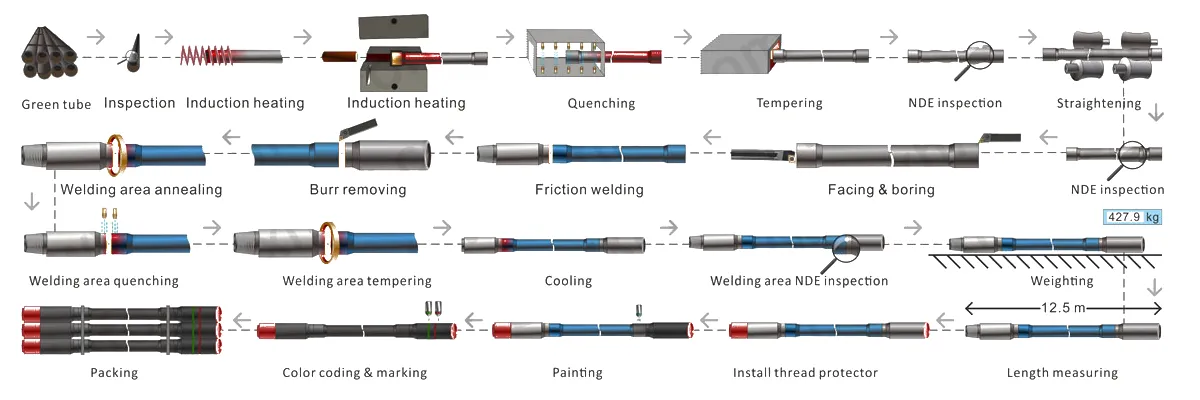

Drill pipes are manufactured through precision inertia welding, heat treatment, and rigorous testing to ensure robust mechanical properties and weld integrity for demanding drilling operations.

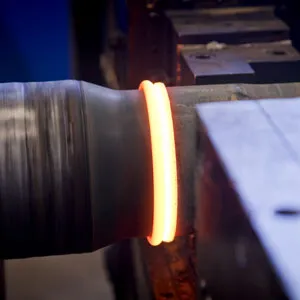

Tool joints are connected to tubes via inertia welding with computer-monitored precision, ensuring concentricity, followed by weld flash removal and heat treatment (austenitization, quenching, tempering) to achieve required mechanical properties.

Post-weld, surfaces are polished, and weld zones undergo hardness testing, ultrasonic testing, and wet magnetic particle inspection, with all parameters electronically recorded for traceability and quality assurance.

Drilling Equipment

Drill pipes and heavy weight drill pipes serve distinct roles in drill strings, differing in structure, weight, and function to optimize torque, fluid transport, and stability in drilling operations.

Drill Pipe: Drill pipe is the basic component of drill string. Its main function is to transmit torque and transport drilling fluid, and the wellbore is continuously deepened by the gradual lengthening of the drill pipe. Seamless steel pipes (9–11mm wall thickness) transmit torque and drilling fluid, deepening wellbores via friction-welded joints, forming the core of the drill string for oil drilling.

Heavy Weight Drill Pipe: Heavier, thicker-walled (2–3 times drill pipe) with extended joints and central wear bands, they enhance rigidity, reduce deviation, and simplify tripping, acting as a transitional component between drill pipe and collars.

Withstands high torque and axial tension in deep drilling.

Coatings protect against H₂S and CO₂ corrosion.

Eliminates weld seams for enhanced structural integrity.

Smooth inner surface reduces friction and optimizes drilling fluid circulation.

Tailored sizes, grades, and connections for specific drilling needs.

Meets API 5DP and API SPEC 7-1 standards.

| Grade | C (% max) | Si (% max) | Mn (% max) | P (% max) | S (% max) | Cr (% max) | Mo (% max) |

|---|---|---|---|---|---|---|---|

| E75 | 0.45 | 0.45 | 1.65 | 0.020 | 0.015 | 0.50 | 0.20 |

| X95 | 0.45 | 0.45 | 1.65 | 0.020 | 0.015 | 0.50 | 0.20 |

| G105 | 0.45 | 0.45 | 1.65 | 0.020 | 0.015 | 1.00 | 0.25 |

| S135 | 0.45 | 0.45 | 1.65 | 0.020 | 0.015 | 1.50 | 0.25 |

| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|---|---|---|

| E75 | 517 | 517–724 | 13 |

| X95 | 655 | 655–862 | 13 |

| G105 | 724 | 724–931 | 13 |

| S135 | 931 | 931–1138 | 13 |

These properties ensure durability and reliability under high torque and pressure in drilling operations.

| Feature | API 5DP Drill Pipe (E75, X95, G105, S135) | API 5CT Casing (J55, K55, N80) | API 5CT Tubing (J55, N80, P110) |

|---|---|---|---|

| Application | Transmits torque and drilling fluid in oil, gas, and geothermal drilling | Lines wellbore to stabilize and prevent collapse | Extracts oil or gas from well to surface |

| Tensile Strength (MPa) | 517–931 | 379–552 | 379–758 |

| Yield Strength (MPa) | 517–1138 | 379–552 | 379–758 |

| Corrosion Resistance | High (H₂S, CO₂ resistant with coatings) | Moderate (basic coatings) | Moderate to high (depends on grade) |

| Seamless Design | Yes (uniform strength, no welds) | Seamless or welded | Seamless or welded |

| Operating Conditions | High torque, pressure, and temperature (up to 300°C) | Static, moderate pressure | Dynamic flow, high pressure |

| Typical Use | Deep well, horizontal, offshore drilling | Wellbore lining, structural support | Oil and gas production |

Why Choose API 5DP Drill Pipes?

Unlike API 5CT casing and tubing, API 5DP

drill

pipes are optimized for dynamic drilling, offering higher tensile and yield strengths, better

corrosion resistance for sour gas environments, and seamless construction for enhanced durability in

high-torque and deep-drilling applications.

| Series | Classification | OD(mm) | WT(mm) | ID(mm) |

|---|---|---|---|---|

| BTW | Drilling Rod | 56.6 | 4.05 | 48.5 |

| Inner Tube | 46.6 | 1.8 | 43 | |

| Outer Tube | 57.2 | 4 | 49.2 | |

| Stop Ring | 60 | 5.6 | 48.8 | |

| NTW | Drilling Rod | 73.1 | 4.4 | 64.3 |

| Inner Tube | 61.5 | 2.05 | 57.4 | |

| Outer Tube | 73.5 | 4.4 | 64.7 | |

| Stop Ring | 75.3 | 5.35 | 64.6 | |

| HTW | Drilling Rod | 91.3 | 5.15 | 81 |

| Inner Tube | 78.4 | 2.8 | 72.8 | |

| Outer Tube | 93 | 5.7 | 81.6 | |

| Stop Ring | 95.45 | 7 | 81.45 |

| Specifications | Steel Grades |

|---|---|

| ASTM A-210 / ASME SA-210 | Gr. A1; C |

| BS 3059-1 | Gr. 320 |

| BS 3059-2 | Gr. 360; 440; 620; 622 |

| EN 17175 | 16Mo3 |

| EN 10216/1 | P235TR1; P235TR2; P265TR1; P265TR2 |

| EN 10216/2 | P235GHTC1; P235GHTC2; P265GHTC1; P265GHTC2 |

| ASTM A-209 ASTM A-213 ASME SA-213 |

Gr. T1; T11; T12; T22; T5; T9; T91; T92 |

| ASTM A-335 / ASME SA-335 | Gr. P1; P11; P12; P22; P5; P9; P91; P92 |

| Grade | Mpa(Yield Strength) | Mpa(Tensile strength) | (%)Elongation | Note |

|---|---|---|---|---|

| R780 | ≥520(Rp0.5) | ≥780 | ≥15(A50) | Standard: JIS G3465-2006 Type and Brand:STMR780 |

| E75 | 517~724(Rp0.5) | ≥689 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen; which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75×6.895=517;135×6.895=931] |

| X95 | 655~862(Rp0.5) | ≥724 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen; which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75×6.895=517;135×6.895=931] |

| G105 | 724~931(Rp0.6) | ≥793 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen; which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75×6.895=517;135×6.895=931] |

| S135 | 931~1138(Rp0.7) | ≥1000 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen; which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75×6.895=517;135×6.895=931] |

| ZT380 | ≥380 | ≥640 | ≥14 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT490 | ≥490 | ≥690 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT520 | ≥520(Rp0.5) | ≥780 | ≥15(A50) | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT540 | ≥540 | ≥740 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT590 | ≥590 | ≥770 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT640 | ≥640 | ≥790 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT740 | ≥740 | ≥840 | ≥10 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT850 | ≥850 | ≥950 | ≥14(A50) | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT950 | ≥950 | ≥1050 | ≥13(A50) | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| DZ40 | ≥392 | ≥637 | ≥14 | YB/T5052-93 DZ50: Min Yield strength of 50Kgf mm² in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ50 | ≥490(50×9.8=490) | ≥686 | ≥12 | YB/T5052-93 DZ50: Min Yield strength of 50Kgf mm² in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ55 | ≥540 | ≥735 | ≥12 | YB/T5052-93 DZ50: Min Yield strength of 50Kgf mm² in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ60 | ≥588(60×9.8=588) | ≥764 | ≥12 | YB/T5052-93 DZ50: Min Yield strength of 50Kgf mm² in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ65 | ≥637 | ≥784 | ≥12 | YB/T5052-93 DZ50: Min Yield strength of 50Kgf mm² in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ75 | ≥735 | ≥833 | ≥10 | YB/T5052-93 DZ50: Min Yield strength of 50Kgf mm² in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

Explore seamless drill pipes with targeted long-tail keywords for specifications, applications, and materials.

Note: Seamless drill pipes meet API standards, ensuring performance and safety. Contact suppliers for detailed specifications.

Applications

Drill pipes are essential for oil and gas drilling, enduring extreme stress, strain, and heat to transmit torque and drilling fluid in harsh environments.

Oil drilling, gas drilling, geothermal drilling, offshore drilling, horizontal drilling, and deep well drilling.

They withstand severe conditions in deep wells, rock formations, and offshore operations, where failure risks costly delays, making robust design critical.

Well design, driven by depth and geology, dictates pipe size, grade, and quantity, with rising demand for high-grade pipes in complex exploration.

Seamless Drill Pipe provides reliable solutions for drilling in oil, gas, and geothermal industries.

Transmits torque and fluid in onshore oil wells.

Handles high-pressure gas extraction.

Withstands high temperatures and corrosive fluids.

Resists corrosion in marine environments.

Supports high-torque directional drilling.

Handles extreme depths and pressures.

Why Choose These Pipes? Their seamless design and high strength ensure safety and efficiency in demanding drilling environments.

Other structural pipes provide high strength and v...

Steel pipe for gas cylinder offers high-strength, ...

Seamless pipes for high-temperature applications o...