Multi-Rifled Seamless Steel Tubes are precision-engineered seamless steel tubes with internal rifling designed to enhance heat transfer efficiency in high-pressure boilers and heat exchangers. Compliant with standards like ASME SA213 and DIN 17175, these rifled boiler tubes optimize thermal performance, offering superior strength and corrosion resistance for demanding industrial applications.

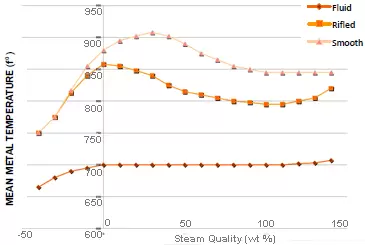

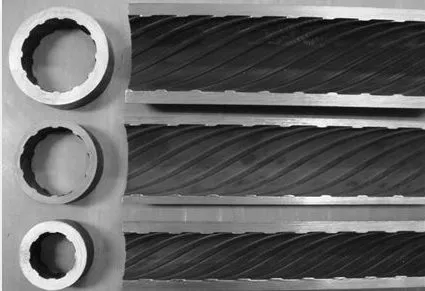

Manufactured from low-carbon or alloy steels, such as SA213 T2, T12, or 15Mo3, seamless heat transfer tubes are produced through cold-drawing or hot-rolling processes, with internal helical ribs formed to increase surface area and promote turbulent flow. Available in outer diameters from 19 mm to 76.2 mm and wall thicknesses from 2 mm to 8 mm, these tubes are ideal for water-tube boilers, superheaters, and heat exchangers. The rifled design enhances heat transfer by up to 30% compared to smooth tubes, improving energy efficiency.

High-strength rifled tubes undergo rigorous testing, including hydrostatic, ultrasonic, and eddy current tests, to ensure defect-free material and compliance with standards. With tensile strengths ranging from 415 MPa (T2) to 510 MPa (T12), these tubes resist thermal stress and high-pressure conditions. Surface treatments like pickling or anti-corrosion coatings enhance corrosion-resistant rifled tubes durability in environments with acidic or high-temperature fluids, such as those in power plants or petrochemical facilities.

Compared to smooth seamless tubes, multi-rifled seamless steel tubes offer superior heat transfer due to their internal ribs, which induce turbulence and improve fluid mixing. This design reduces fouling and scaling, extending tube lifespan. Customizable rifling patterns (e.g., 4, 6, or 8 ribs) and dimensions meet specific boiler or exchanger requirements, addressing challenges like thermal inefficiency and material degradation.

From power generation to chemical processing, rifled boiler tubes deliver reliable, efficient, and safe solutions for heat transfer applications. Their advanced design and compliance with international standards make them a preferred choice for optimizing thermal performance in industrial systems.

Comparison with Other Grade Pipes

Multi-Rifled Seamless Steel Tubes (SA213 T2, T12, 15Mo3) are optimized for enhanced heat transfer in boilers, offering superior thermal efficiency compared to smooth seamless tubes or standard pressure pipes like ASTM A106. Below is a comparison highlighting differences in application, heat transfer, and strength.

Comparison of Multi-Rifled Seamless Tubes with ASTM A179 and ASTM A106 Pipes| Feature | Multi-Rifled Tubes (SA213 T2, T12, 15Mo3) | ASTM A179 Smooth Tubes | ASTM A106 Pipe (Grade B) |

|---|

| Application | High-pressure boilers, superheaters, heat exchangers | Heat exchangers, condensers | High-temperature pressure piping |

| Tensile Strength (MPa) | 415–600 | 325 | 415 |

| Yield Strength (MPa) | 205–270 | 180 | 240 |

| Heat Transfer Efficiency | High (rifling increases by up to 30%) | Moderate (smooth surface) | Low (not designed for heat transfer) |

| Corrosion Resistance | High (coatings for acidic fluids) | Moderate (basic coatings) | Moderate (depends on environment) |

| Seamless Design | Seamless with internal rifling | Seamless, smooth | Seamless |

| Operating Conditions | High thermal stress, high pressure | Moderate thermal stress | High temperature, pressure |

Why Choose Multi-Rifled Tubes?

Unlike smooth ASTM A179 tubes or ASTM A106 pipes, multi-rifled tubes provide enhanced heat transfer efficiency due to internal ribs, making them ideal for high-pressure boilers and superheaters requiring optimal thermal performance.

Key Benefits

Enhanced Heat Transfer

Rifling increases efficiency by up to 30%.

Corrosion Resistance

Coatings protect against acidic and high-temperature fluids.

High Strength

Withstands high pressure and thermal stress.

Reduced Fouling

Rifled design minimizes scaling and deposits.

Customizable Rifling

Tailored rib patterns for specific applications.

Standards Compliance

Meets ASME SA213 and DIN 17175 standards.