Carbon Steel Seamless Pipes

High-strength Seamless Pipes For Boilers And High-pressure Systems

Carbon steel seamless pipes offer high strength and corrosion resistance for boilers, heat exchangers, and high-pressure applications.

High-strength Seamless Pipes For Boilers And High-pressure Systems

Carbon steel seamless pipes offer high strength and corrosion resistance for boilers, heat exchangers, and high-pressure applications.

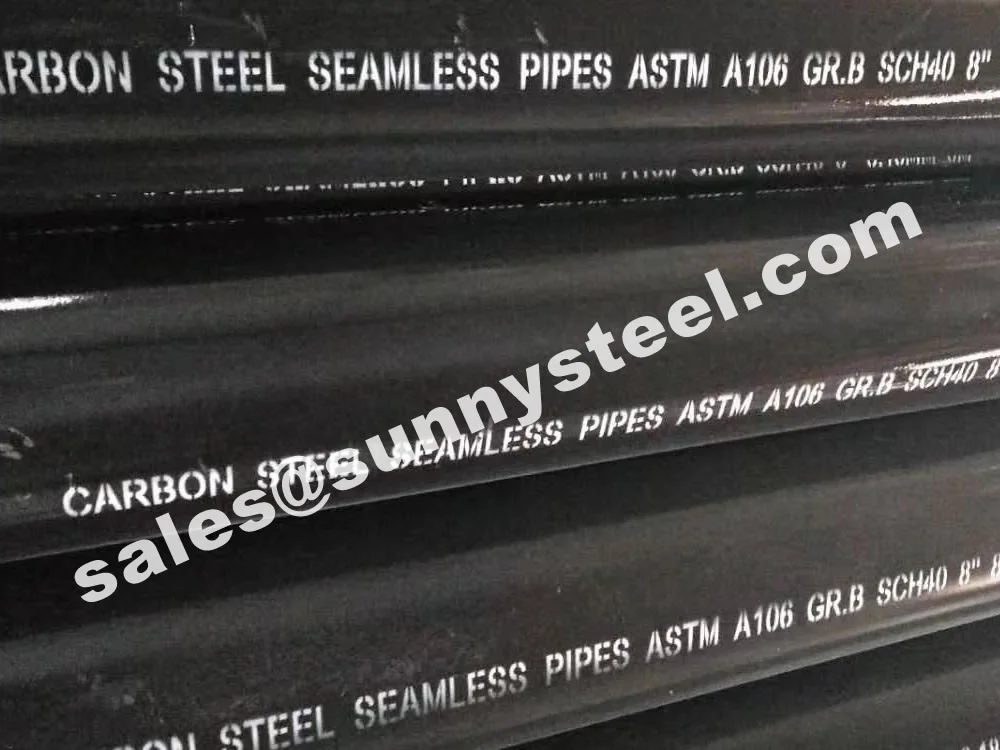

Carbon Steel Seamless Pipes are robust, high-strength pipes designed for demanding applications in boilers, heat exchangers, and high-pressure systems. Compliant with standards such as ASTM A106, ASTM A53, and ASME SA179, these seamless boiler pipes offer excellent durability, corrosion resistance, and thermal conductivity for industrial environments.

Manufactured from high-quality carbon steel grades like A106 Grade B, A53 Grade B, or SA179, these high-pressure carbon pipes are produced through hot-rolling or cold-drawing processes to ensure uniform structure and precise dimensions. Available in outer diameters from 10.3 mm to 610 mm and wall thicknesses from 1.2 mm to 40 mm, they are suitable for applications requiring high pressure and temperature resistance, such as power generation, oil and gas, and chemical processing.

Corrosion-resistant seamless pipes undergo rigorous testing, including hydrostatic, tensile, and flattening tests, to ensure defect-free material and compliance with standards. With tensile strengths ranging from 415 MPa (A106 Grade B) to 325 MPa (SA179), these pipes withstand thermal stress and high-pressure conditions. Surface treatments like black varnish, 3LPE, or galvanizing enhance durability in corrosive environments, such as those involving acidic fluids or high humidity.

Compared to welded pipes, carbon steel seamless pipes offer superior strength and pressure resistance due to their seamless construction, eliminating weak points. They are ideal for critical applications like boiler pipelines, where safety and reliability are paramount. Customizable lengths (up to 12 meters or tailored) and end finishes (plain, beveled, or threaded) ensure compatibility with diverse system designs.

From high-pressure boiler systems to petrochemical refineries, seamless boiler pipes provide reliable, efficient, and cost-effective solutions for fluid and gas transport. Their robust construction and compliance with international standards make them a preferred choice for industrial piping needs.

Carbon Steel Seamless Pipes (A106 Grade B, A53 Grade B, SA179) are optimized for high-pressure and high-temperature applications, offering superior strength compared to welded pipes or alloy steel pipes like SA213 T11. Below is a comparison highlighting differences in application, strength, and corrosion resistance.

| Feature | Carbon Steel Seamless Pipes (A106 B, A53 B, SA179) | Carbon Steel Welded Pipes (A53 Grade B) | SA213 T11 Alloy Pipes |

|---|---|---|---|

| Application | Boilers, heat exchangers, high-pressure piping | Low to medium pressure fluid transport | High-temperature heat exchangers, boilers |

| Tensile Strength (MPa) | 325–415 | 415 | 415 |

| Yield Strength (MPa) | 180–240 | 240 | 205 |

| Corrosion Resistance | Moderate to high (with coatings) | Moderate (weaker at weld seams) | High (alloyed for corrosive environments) |

| Construction | Seamless | Welded | Seamless |

| Operating Conditions | High pressure, moderate to high temperature | Low to medium pressure | High temperature, moderate pressure |

Why Choose Carbon Steel Seamless Pipes? Unlike welded pipes, seamless pipes eliminate weak points, offering superior strength and pressure resistance. Compared to alloy pipes like SA213 T11, they provide a cost-effective solution for high-pressure applications with moderate corrosion requirements.

Seamless carbon steel pipes offer high pressure resistance, good toughness, and fewer joints, making them ideal for demanding industrial applications, though they are costly and prone to corrosion.

Advantages: Seamless carbon steel pipes excel in high-pressure environments due to their weld-free construction, providing superior strength and toughness. Their long pipe sections reduce the need for joints, enhancing reliability and simplifying installation. However, they are expensive and susceptible to corrosion, which can shorten their service life compared to corrosion-resistant alternatives.

Selection Criteria:

Ordinary Seamless Carbon Steel Pipe: Made from ordinary or high-quality carbon steel, low alloy, or alloy structural steel, these pipes offer high strength and are widely used for pipelines with working pressure below 1.6MPa. Applications include heat pipes, refrigeration pipes, compressed air, oxygen, acetylene, and chemical pipes (except for highly corrosive media).

Stainless Steel Seamless Pipe: Composed of chromium-nickel stainless steel, available in hot-rolled or cold-rolled (cold-drawn) forms, these pipes provide strong acid and corrosion resistance. They are ideal for chemical pipelines with special requirements but are more expensive.

Welded Steel Pipes for Low-Pressure Fluid Delivery: Made from Q215-A, Q235-A, or Q255-A carbon steel, these seamed pipes come in galvanized (white iron) or non-galvanized (black iron) forms, with threaded or non-threaded ends. Ordinary types withstand 2.0MPa, while thickened types handle 3.0MPa. They are suitable for low-pressure applications like indoor heating, steam, hot water (≤1.0MPa, ≤200°C, ≤100mm diameter), compressed air (≤0.8MPa, ≤65mm diameter), and gas or clean water pipelines (≤50mm diameter).

Selecting the appropriate seamless or welded carbon steel pipe depends on factors like pressure, temperature, corrosion resistance, and cost, ensuring optimal performance in industries such as oil and gas, chemical, and heating systems.

Industrial Materials

Carbon steel pipes are manufactured in various types, each designed with specific compositions and features to meet diverse industrial needs, offering strength, durability, and corrosion resistance.

Composed of carbon and iron with trace amounts of silicon, manganese, and copper, these pipes are strong, stress-resistant, and ideal for heavy-duty applications in industries like oil and gas, petrochemical, and power generation.

Featuring a minimum tensile strength of 415MPa and yield strength of 205MPa, these pipes contain carbon, manganese, phosphorus, sulfur, silicon, chromium, and molybdenum. They offer high durability, wear resistance, hardness, and corrosion resistance, suitable for high-temperature environments.

Known for high durability, corrosion resistance, and tensile strength, these pipes serve industries such as oil and gas, chemical, metallurgical, energy, ships, desalination, food, and pulp and paper.

Designed for high-pressure conditions, these pipes are used in water and waste transport, oil and gas, and chemical manufacturing, offering reliable performance in demanding applications.

Lightweight, corrosion-resistant, and precision-engineered, ERW pipes are used in shipbuilding, automotive, boilers, railways, oil and petrochemicals, coal and mining, transmission towers, and heavy engineering.

Featuring easy installation, seamless finish, and rustproof properties, these expensive pipes are used in high-value applications like oil and gas, but less commonly in non-energy applications like water pipelines.

Seamless construction ensures durability under high pressure.

Coatings like 3LPE or galvanizing protect against corrosion.

Suitable for boilers, heat exchangers, and pipelines.

Available in various sizes and end finishes.

Resists high temperatures in boiler systems.

Meets ASTM A106, A53, and ASME SA179 standards.

Industrial Materials

Seamless carbon steel pipes, manufactured without welds, provide superior strength and reliability for high-pressure and high-temperature applications in various industries.

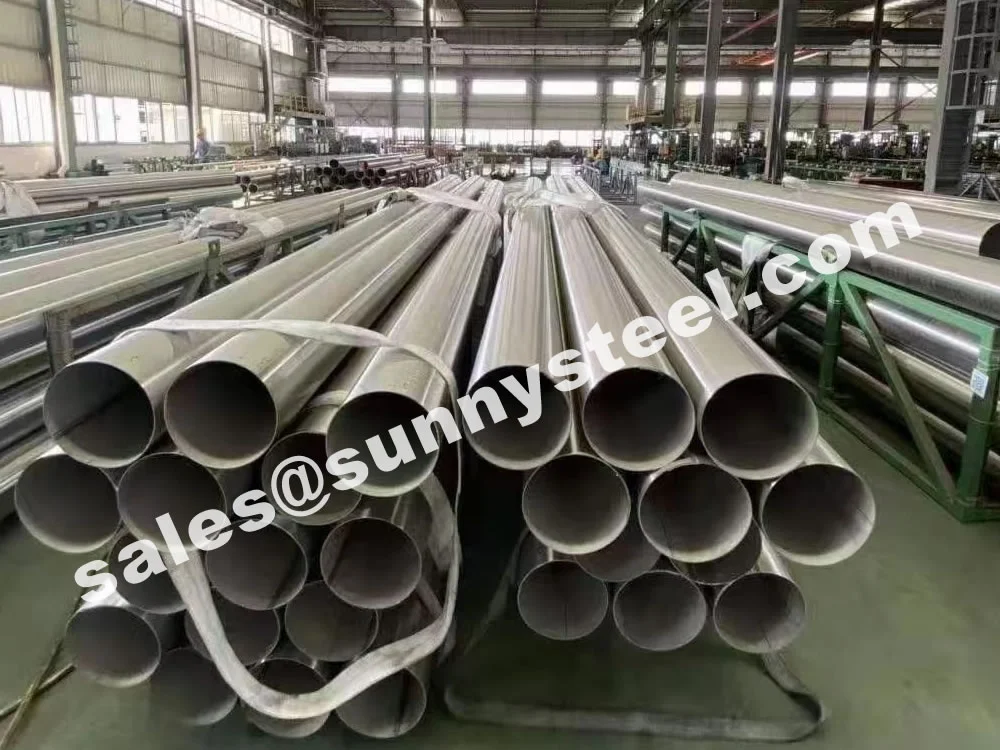

Seamless carbon steel pipes are created by piercing a solid billet of carbon steel to form a hollow tube, eliminating weld seams. This seamless construction enhances their durability and strength, making them ideal for critical applications in industries like oil and gas, petrochemical, power generation, and refineries. They efficiently convey fluids and gases such as water, oil, natural gas, and steam, ensuring smooth flow and reducing the risk of leaks or failures.

The absence of welds in seamless carbon steel pipes ensures reliable performance under extreme conditions, supporting safe and efficient operations across industrial applications.

Quality Assurance

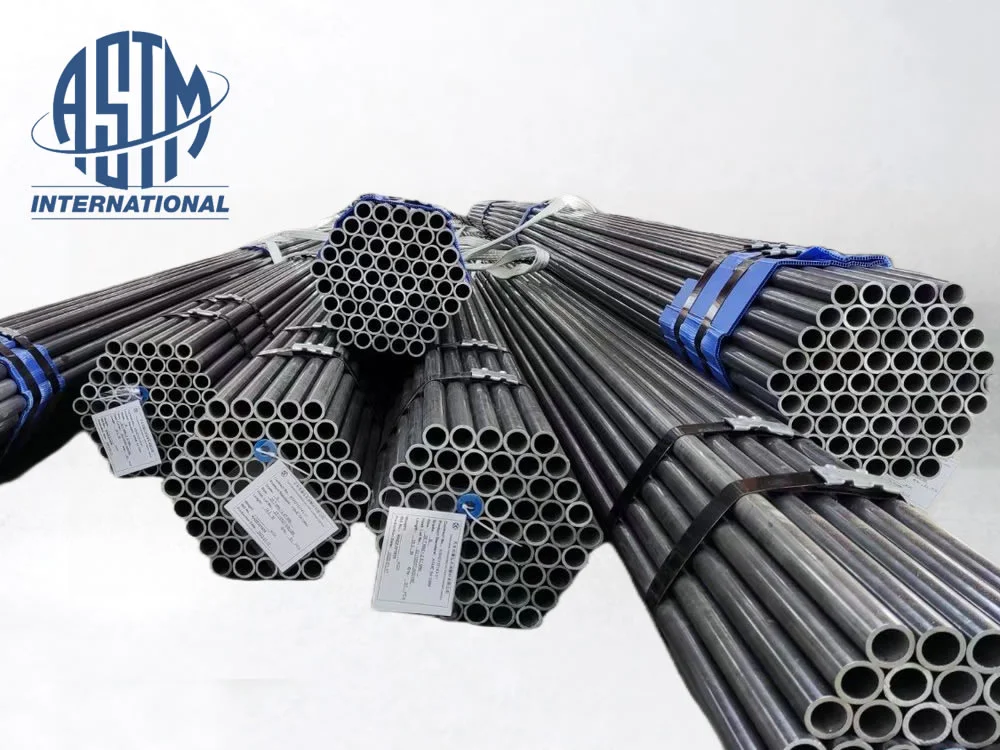

The inspection of seamless carbon steel pipes ensures their quality, safety, and compliance with industry standards and customer specifications for reliable performance.

The inspection process for seamless carbon steel pipes involves multiple rigorous steps to verify their integrity and suitability for high-pressure and high-temperature applications. These steps include non-destructive testing (NDT) methods such as Radiographic Testing (RT), Ultrasonic Testing (UT), Magnetic Particle Testing (MT), or Penetrant Testing (PT) to detect internal and surface defects without damaging the pipe.

Additional checks include heat treatment verification (if specified), metallographic examination (where applicable) to assess material structure, and visual and dimensional controls to ensure accurate size and surface quality. Hydrostatic testing may be conducted to confirm the pipe's ability to withstand pressure. Final inspections cover painting, coating, marking, and color coding, as well as packaging and quantity verification to ensure compliance with standards like ASTM A53, ASTM A106, and API 5L.

These comprehensive inspections guarantee that seamless carbon steel pipes meet the stringent requirements of industries such as oil and gas, petrochemical, and power generation, ensuring durability and safety in critical applications.

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Casting | API 5CT | Ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | Ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Line Pipes | API 5L | Ø10.3~1200 x WT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| Material (Grade) | Tensile strength (MPa) | Yield strength (MPa) | Elongation(%) | Hardness |

|---|---|---|---|---|

| 20G | 410~550 | 245 | ≥24 | --- |

| 20MnG | ≥415 | ≥240 | ≥22 | --- |

| 25MnG | ≥485 | ≥275 | ≥20 | --- |

| 12CrMoG | 410~560 | ≥205 | ≥21 | --- |

| 15CrMoG | 440~640 | ≥235 | ≥21 | --- |

| SA-210C | ≥415 | ≥255 | ≥30 | ≤143HBW |

| SA-210A1 | ≥485 | ≥275 | ≥30 | ≤179HBW |

| SA-213T2 | ≥415 | ≥205 | ≥30 | ≤163HBW |

| SA-213T12 | ≥415 | ≥220 | ≥30 | ≤163HBW |

| Material (Grade) | Heat treatment |

|---|---|

| 20G | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 20MnG | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 25MnG | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 12CrMoG | 900°C~930°C normalizing; 670°C~720°C tempering, holding time: Periodic furnace is more than 2h, continuous furnace is more than 1h. |

| 15CrMoG | Normalizing at 930°C~960°C; tempering at 680°C~720°C, holding time: periodic furnace greater than 2h, continuous furnace greater than 1h. |

Explore carbon steel seamless pipes with targeted long-tail keywords for specifications, applications, and materials.

Note: Carbon steel seamless pipes meet international standards, ensuring durability and performance. Contact suppliers for detailed specifications.

Carbon Steel Seamless Pipes are indispensable in modern industrial processes, offering high strength, corrosion resistance, and versatility for critical applications across multiple industries.

Transports oil, natural gas, and fluids with high strength and durability.

Used in structural applications like building frames and supports.

Manufactures exhaust systems, chassis, and other components.

Conveys steam and hot gases in boilers and heat exchangers.

Fabricates machinery and equipment components.

Supports water supply, sewerage, and drainage systems.

Handles corrosive fluids and chemicals in processing plants.

Used in piping systems and structural components.

Produces parts and assemblies in various processes.

Why Choose Carbon Steel Seamless Pipes? Their seamless design, high strength, and corrosion resistance make them ideal for critical applications across oil and gas, construction, automotive, power generation, and more, ensuring reliable performance and longevity.

Precision seamless pipes offer high dimensional ac...

Astm seamless pipes offer high strength, corrosion...

Din en steel pipes offer seamless and welded solut...

High-quality steel pipes manufactured to Chinese G...

Jis seamless pipes, compliant with japanese indust...