Precision Steel tube

High-accuracy Seamless Tubes For Automotive And Hydraulic Systems

Precision seamless pipes offer high dimensional accuracy and corrosion resistance for automotive, hydraulic, and mechanical applications.

High-accuracy Seamless Tubes For Automotive And Hydraulic Systems

Precision seamless pipes offer high dimensional accuracy and corrosion resistance for automotive, hydraulic, and mechanical applications.

CDS

Precision steel tubes are high-quality carbon or alloy steel tubes engineered for exceptional dimensional accuracy, smooth surfaces, and superior mechanical properties, ideal for demanding applications.

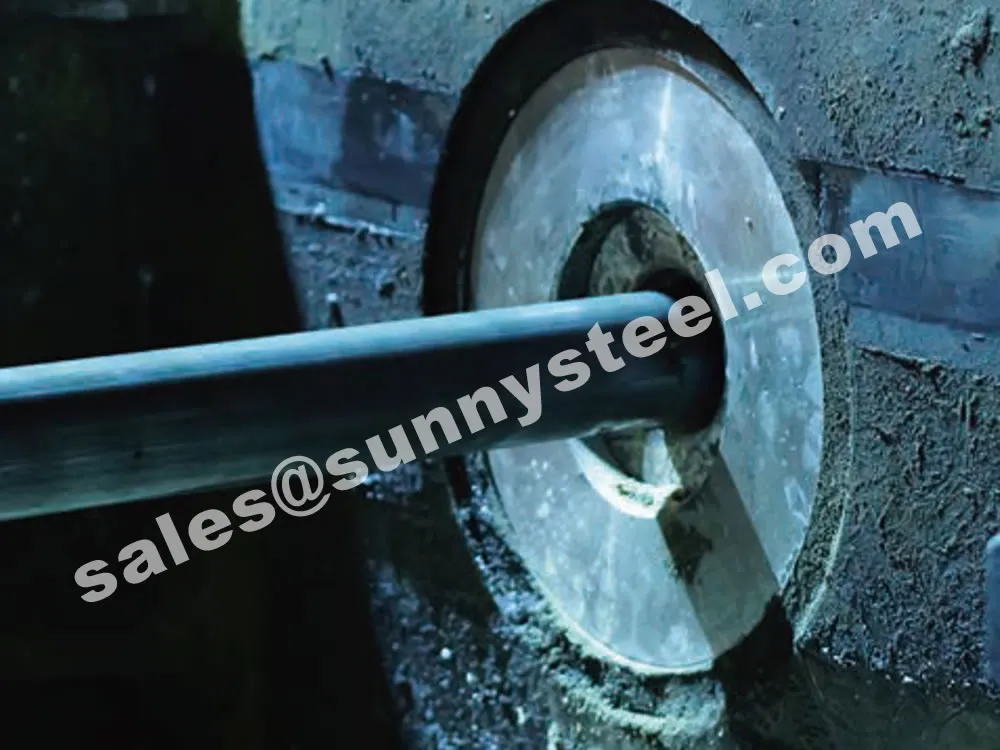

Manufactured through cold-drawing or cold-rolling, these seamless hydraulic tubes comply with standards like DIN 2391, EN 10305-1, and ASTM A519, using grades such as ST35, ST45, or ASTM A519 1020. With tight tolerances (±0.05 mm) and excellent surface finish (Ra ≤ 0.8 µm), they are designed for automotive, hydraulic, and mechanical engineering applications, including hydraulic cylinders, fuel injection systems, and precision bearings.

These tubes undergo rigorous testing, including dimensional checks, tensile tests, and surface inspections, to ensure defect-free quality. With tensile strengths from 340 MPa (ST35) to 600 MPa (ST52) and surface treatments like phosphating or galvanizing, they offer robust performance and corrosion resistance. Compared to standard seamless tubes, precision steel tubes reduce machining needs due to their superior accuracy and smoother surfaces, with customizable lengths (up to 6 meters) and end finishes.

Precision steel tubes deliver unmatched accuracy, strength, and corrosion resistance, making them a preferred choice for high-performance applications in hydraulic systems and automotive manufacturing.

Design according to usage and processing procedures. Precision tubes especially for automotive components.

International alloy steel available (ST52, 4130, 25CrMo4). Full range of sizes and high precision.

Trial order: 3 tons to win trust.

The more you order, the better the price.

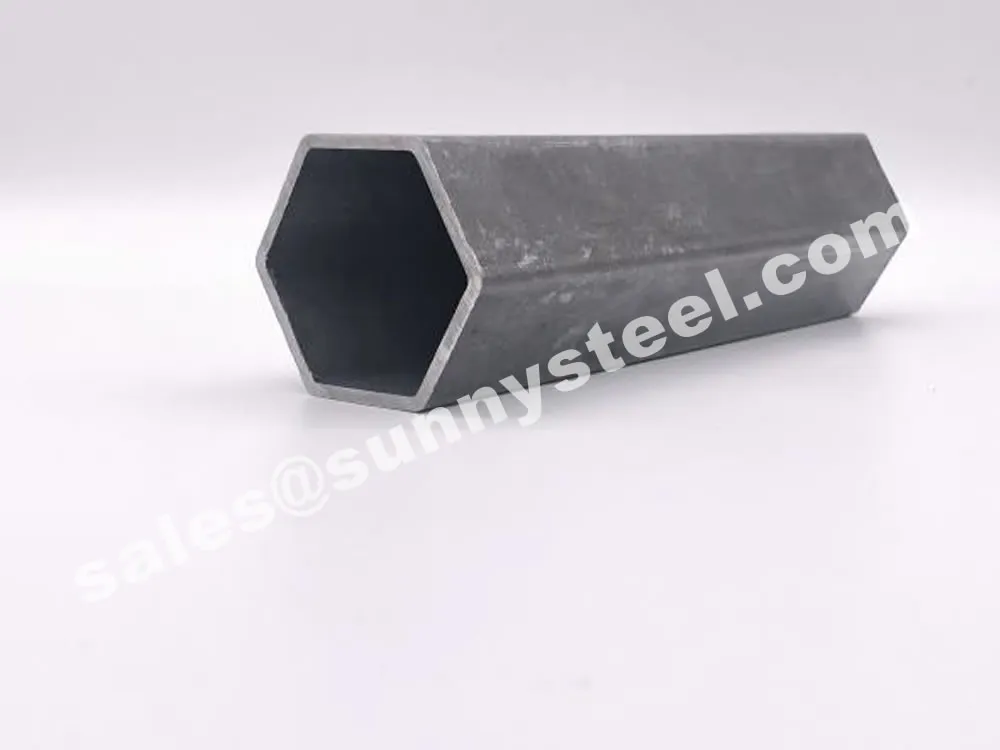

Hexagonal, Triangle, Splined, Trapezoidal, Square, fin tube, and more.

Exactly based on drawings.

Specializing in thick-wall tubes.

What Are

Standard precision tubes, produced through cold drawing, offer high dimensional accuracy and smooth surfaces, making them ideal for automotive and mechanical applications.

Precision steel tubes from our production satisfy the requirements for the following applications: components for the vehicle drivetrain, cars suspension systems, fuel injection, components for engine and transmission, components for body and chassis, vehicle control systems and others.

With their exceptional accuracy and surface finish, standard precision tubes are a preferred choice for automotive and mechanical engineering, enabling efficient production of high-performance components.

| Outer Diameter (OD) | Wall Thickness (WT) |

|---|---|

| 4.0 – 125.0 mm | 0.5 – 12.0 mm |

| EN 10305-1 | ASTM 519, SAE1-2 | JIS G3445 | DIN 239 |

|---|---|---|---|

| E215, E235, E255, E355, E410, 26Mn5, 26Mo2, C35E, C45E, 25CrMo4, 42CrMo4, 25CrMo4 | 1008, 1010, 1012, 1015, 1016, 1017, 1018, 1019, 1020, 1021, 1022, 1025, 1026, 1030, 1035, 1040, 1045, 1050, 1518, 4130, 4140, 4142, 8617. | STKM11A, STKM12A, STKM12B, STKM12C, STKM13A, STKM13B, STKM13C, STKM14A, STKM14B, STKM14C, STKM15A, STKM15C, STKM16A, STKM16C, STKM17A, STKM17C, STKM18A, STKM18B, STKM18C, STKM19A, STKM19C, STKM20A | St35, St45, St52. |

| Standard | Grade |

|---|---|

| European Standards | EN 10305-1, DIN 2391, BS 6323/4, NF A 49-310, NF A 49-312, UNI 7945, STN/ČSN 42 6711, STN/ ČSN 42 6712, PN-H 74240, PN-H 74220 |

| Russian Standards | GOST 8734, 9567, 12132 |

| American Standards | ASTM A450, A519 |

| Japanese Standards | JIS G3445 |

| Designation | Symbol | Description | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Cold drawn/hard | +C | No heat treatment after the final cold drawing process | |||||||

| Cold drawn/soft | +LC | After the final heat treatment there is a suitable drawing pass | |||||||

| Cold drawn and stress relieved | +SR | After the final cold drawing process there is a stress relief heat treatment in a controlled atmosphere | |||||||

| Annealed | +A | After the final cold drawing process the tubes are annealed in a controlled atmosphere | |||||||

| Normalized | +N | After the final cold drawing operation the tubes are normalized in a controlled atmosphere | |||||||

| Material Type | Grades |

|---|---|

| Carbon Steel | 10#, 20#, 35#, 45#, 55#, Q235B, CF53, A105, 65Mn |

| Alloy Steel | 16Mn(Q345/Q355), 20Cr, 40Cr, 15CrMo, 20CrMo, 30CrMo, 35CrMo, 42CrMo, 20CrMnTi, 20CrMnMo, 40MnMoV, 20Mn2, 40Mn2, 37Mn5, ZF6, 16MnCr5, 20MnCr5, 36Mn2, 38Mn2V, 15Mo3, 16Mo3, 25CrMo4, 34MnB5, 20CrNiMo, 40CrNiMo, 31CrMoV9, 38CrMoAl |

| Free Cutting Steel | 1215 |

| Others | Special Material can be customized |

| Type of Steel | GB (China) | ASTM A519 | DIN | JIS3445/JIS G4051 | OCT 4543-71 |

|---|---|---|---|---|---|

| Carbon Steel | 10# | 1010 | C10/CK10 | SKM11A/S10C | 10 |

| 20# | 1020/1018 | C22/CK22 | STKM12A/12B/12C | 20 | |

| Q235B | S235JO(1.0114) | SS400 | Cr3K II | ||

| 25# | 1026 | STKM13A/13B/13C/S25C | 25 | ||

| 35# | 1035 | C35/CK35 | 35 | ||

| 45# | 1045 | C45/CK45 | 45 | ||

| 55# | CF53 | 55 | |||

| 65Mn | 1566 | 65┌ | |||

| Alloy Steel | 16Mn(Q345/Q355) | St52 | |||

| Q345A/Q355A | Grade 50[345] | E355(1.0060) | SPEC590 | 345 | |

| Q345B/Q355B | S355JR(1.0045) | ||||

| Q345C/Q355C | S355J0(1.0553) | ||||

| Q345D/Q355D | S355J2(1.0577) | ||||

| Q345E/Q355E | S355NL(1.0546) | ||||

| 20Cr | 5120 | 20Cr4(EN10084-1998) | JIS SCr420(JIS G4053) | 20X | |

| 40Cr | 5140 | 41Cr4(1.7035) | JIS SCr440(JIS G4053) | 40X | |

| 15CrMo/15CrMoG | 15CrMo4 | SCM415(JIS 4053) | 15XM | ||

| 20CrMo | 18CrMo4(1.7243) | SCM420(JIS 4053) | 20XM | ||

| 30CrMo | 4130 | 25CrMo4(1.7225) | SCM430 | 30XM | |

| 35CrMo | 4135 | 35CrMo4(1.7220) | SCM432/SCRRM3 | 35XM | |

| 42CrMo | 4140 | 42CrMo4(1.6511) | SCM440 | ||

| 20CrNiMo | 8620 | 20NiCrMo2-2(1.6523) | SNCM220 | 20XH2M(20HM) | |

| 40CrNiMo | 4340/E4340 | 36CrNiMo4(1.6511) | SNCM439 | 40XH2MA | |

| 20CrMnTi | 18X┌T | ||||

| 20Mn2 | 1524 | SMn420 | |||

| 40Mn2 | 1340 | SMn438 | 40┌2 | ||

| 15CrMn | 5115 | 16MnCr5(1.7131) | 18X┌ | ||

| 20CrMn | 5120 | 20MnCr5(1.7147) | SMnC420 | 18X┌ | |

| 20CrMnMo | SCM421 | ||||

| Free Cutting Steel | Y15 | 1213 | 11SMn30(1.0718) | SUM22 | A12 |

| 1215 | 11SMn37(1.0736) | SUM22 | A11 | ||

| Tube Steel | GB/T 8162-2018 | ASTM A519/A530 | DIN17121/EN 10297-1 | JIS G3441/JIS G3444/JIS G3445 | |

| GB/T 8163-2018 | ASTM A106 | ||||

| GB3639-2021 | DIN1629/DIN2391/EN10305-1 | GOST 8733-74 GOST 8734-75 (St.20, 09G2S) |

|||

| GB/T 3094-2012 | ASTM A500/ASME SA500 | GOST 8645-68/ GOST 8639-82 |

|||

| GB/T3087-2008 | ASTM A179 | JIS G3461/JIS G3462 | |||

| Precision Welded Tubes | DIN EN10305-2/DIN EN10305-3 | ||||

| Rebar Coupler | JG/T 163-2013 | According to BS4449, B500, ASTM A615 Grade 40/Grade 60/Grade 75 | |||

| Designation | Symbol (EN 10305-1) | Description (EN 10305-1) | Symbol (DIN 2391-2 / ASTM 519) | Description (DIN 2391-2 / ASTM 519) |

|---|---|---|---|---|

| Cold drawn / hard | +C | No heat treatment after the final cold forming. | +C | No heat treatment after the final cold drawing process. |

| Cold drawn / soft | +LC | After the last heat treatment, there is a light finishing pass (cold drawing). | +LC | After the final heat treatment, there is a suitable drawing pass. |

| Cold drawn and stress relieved annealed | +SR | After the final cold drawing process, the tubes are stress relieved annealed in a controlled atmosphere. | +SR | After the final cold drawing process, there is a stress relief heat treatment in a controlled atmosphere. |

| Annealed | +A | After the final cold drawing process, the tubes are annealed in a controlled atmosphere. | +A | After the final cold drawing process, the tubes are annealed in a controlled atmosphere. |

| Normalized | +N | After the final cold drawing process, the tubes are normalized in a controlled atmosphere. | +N | After the final cold drawing operation, the tubes are normalized in a controlled atmosphere. |

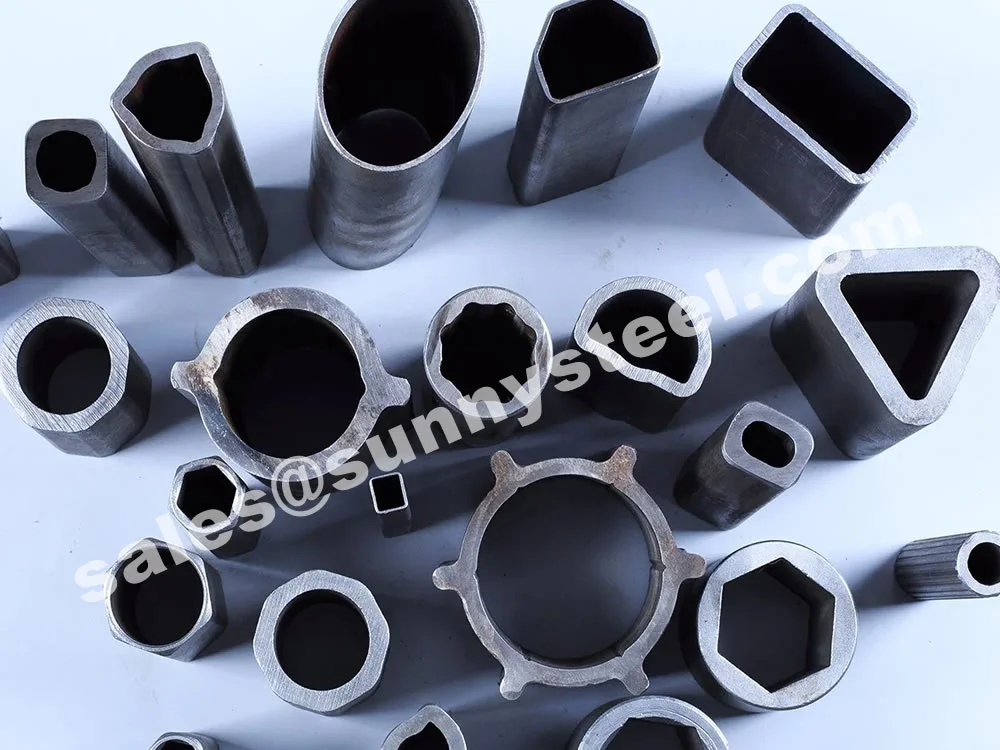

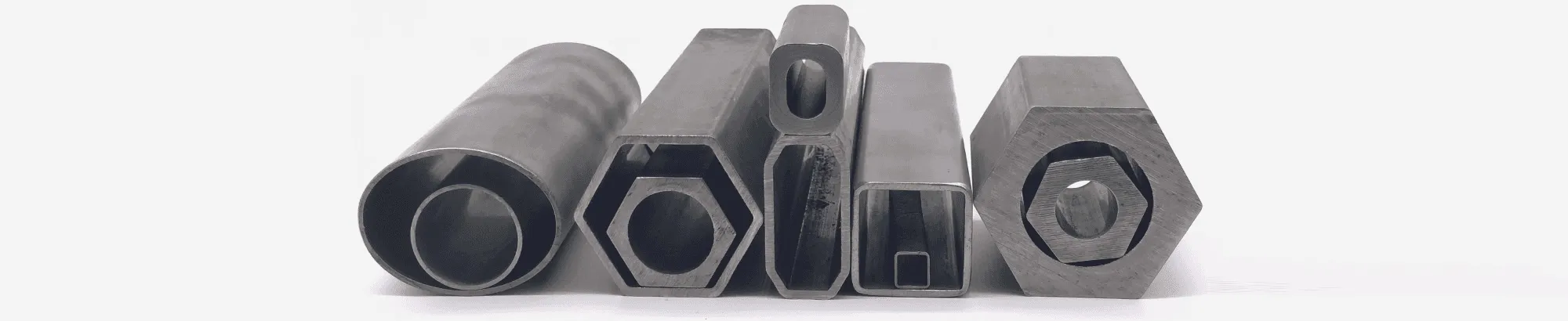

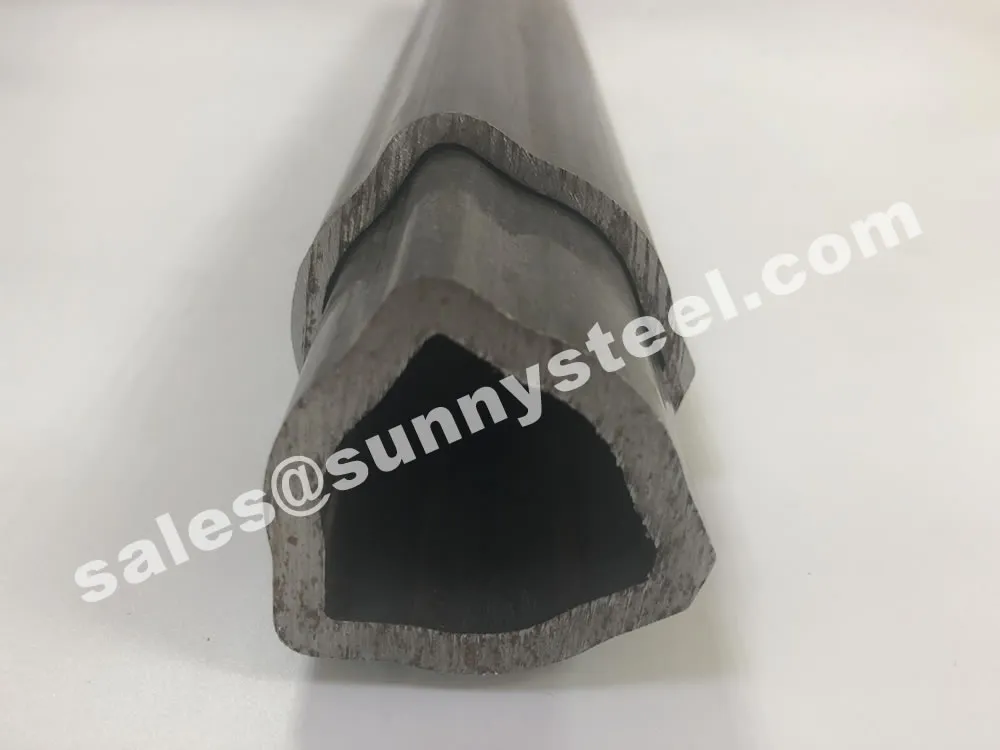

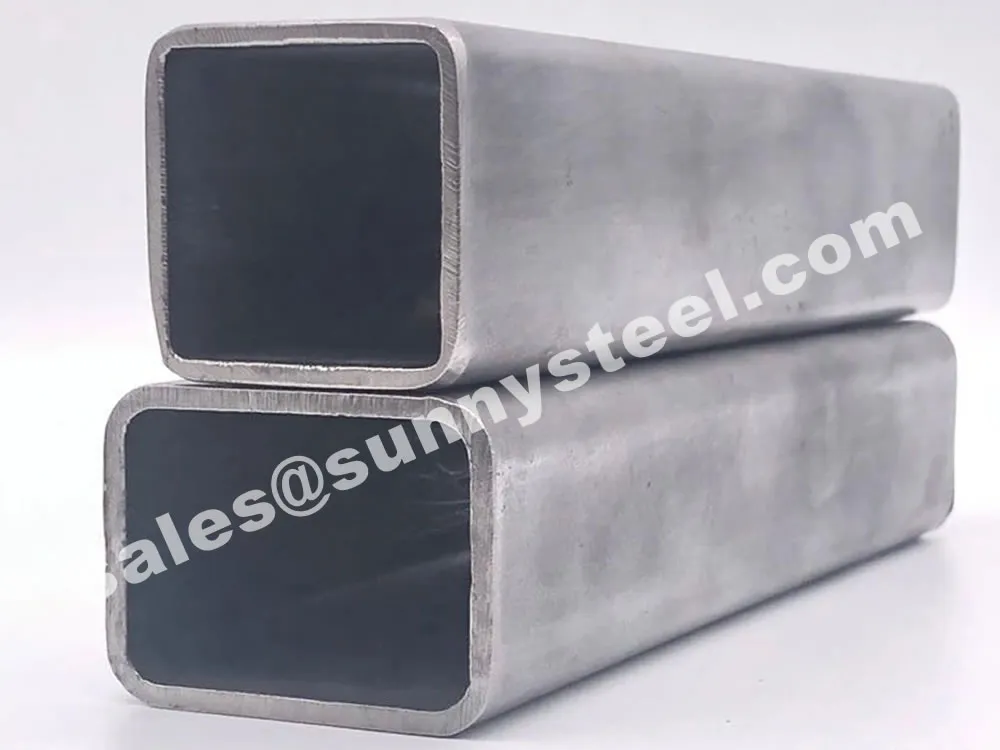

A shaped seamless steel tube refers to a seamless steel tube that has been formed into a specific shape or profile.

Outside Hexagonal Tube

Inside Hexagonal Tube

Hexagonal Tube

Lemon Profile Tube

Triangle Profile Tube

Rectangular Seamless Tube

Square Seamless Tube

Splined Tube

Trapezoidal Tube

D Shape Tube

Oval Seamless Tube

Explore precision steel tubes with targeted long-tail keywords for specifications, applications, and materials.

Note: Precision steel tubes meet international standards, ensuring high accuracy and performance. Contact suppliers for detailed specifications.

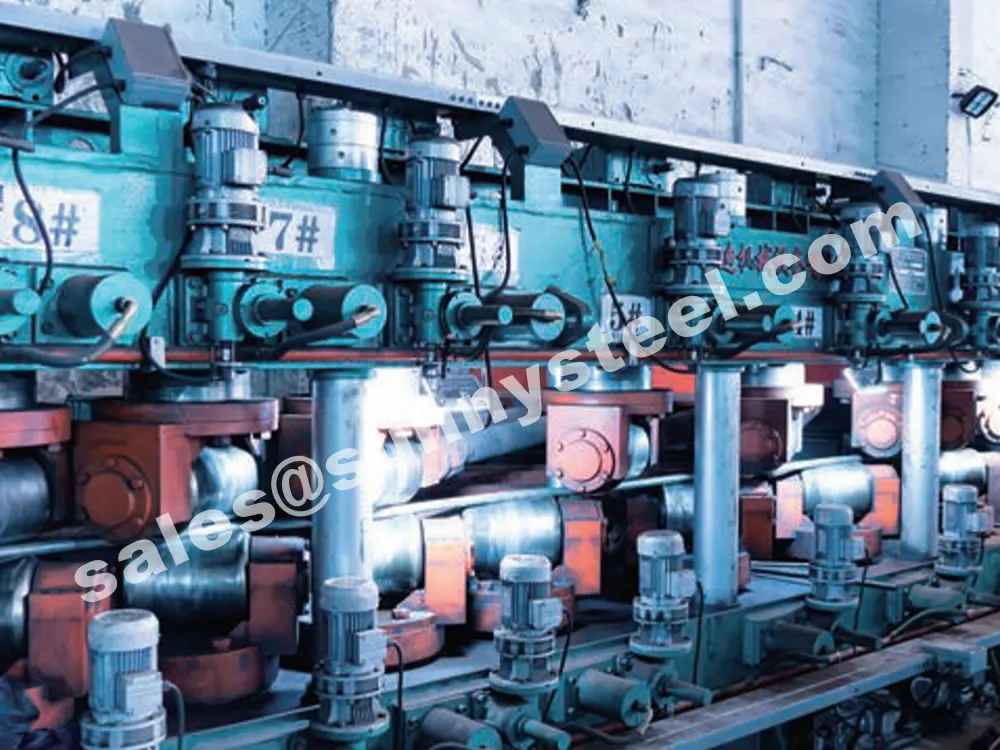

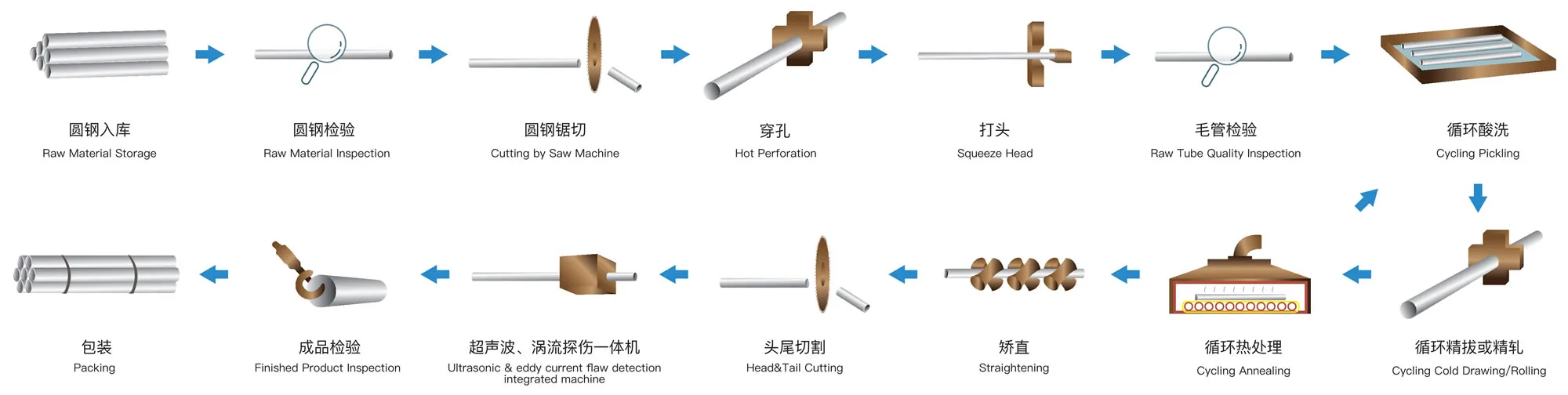

Raw material storage

Hot perforation

Cycling pickling

Cycling annealing

Ultrasonic & eddy current flaw

Straightening

Cold rolling

Cold drawing

Explore common defects encountered in the production process of seamless steel tubes, along with potential causes and solutions.

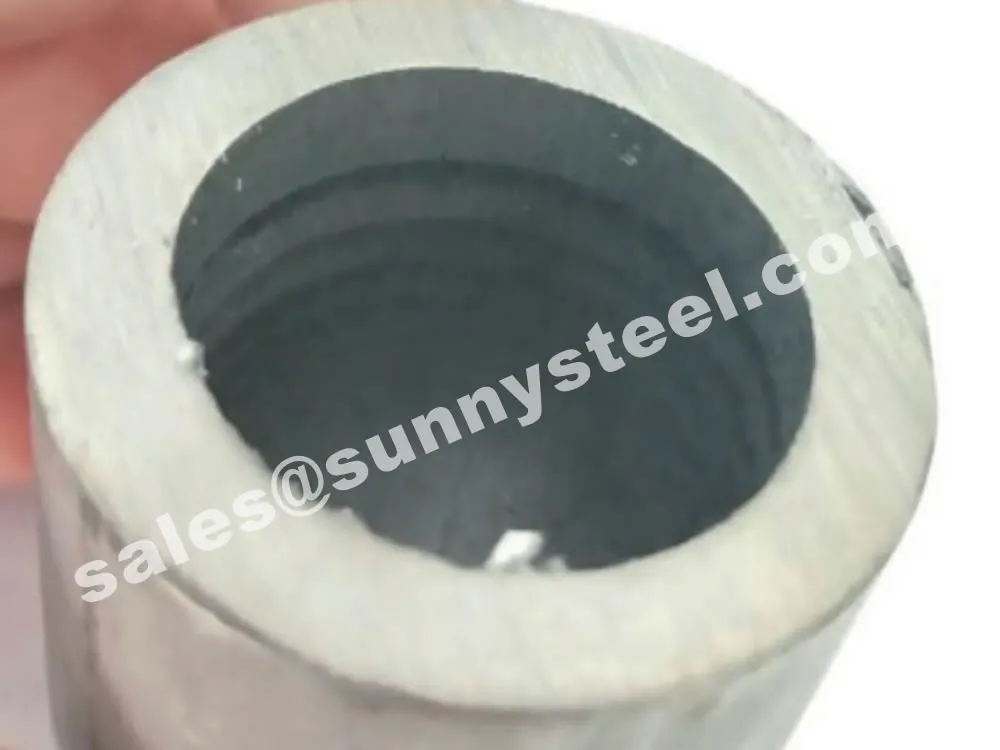

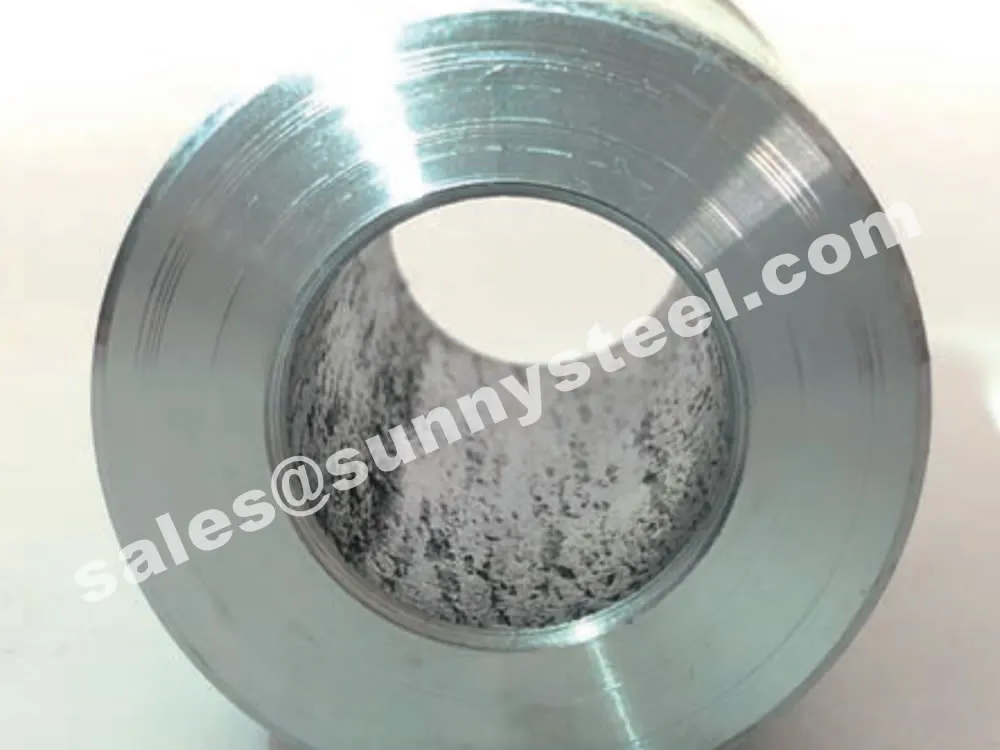

Tube cracking

In&Out Peeling

In&Out Scratch

Bad straightness

Eccentricity

Imperfections

Internal trembling marks

Internal pits

Precision Steel Tubes are critical for high-precision applications requiring tight tolerances and smooth surfaces, serving industries like automotive, hydraulic systems, and mechanical engineering with unmatched reliability.

Hydraulic System

Fire Fighting Accessories

Fastener - High Strength Nut

Triangular Drill Pipe

Agricultural Drive Shaft

Pre-stressed Anchoring Nut

Why Choose Precision Steel Tubes? Their high dimensional accuracy, smooth surfaces, and robust construction ensure reliable performance in demanding applications requiring precision and durability.

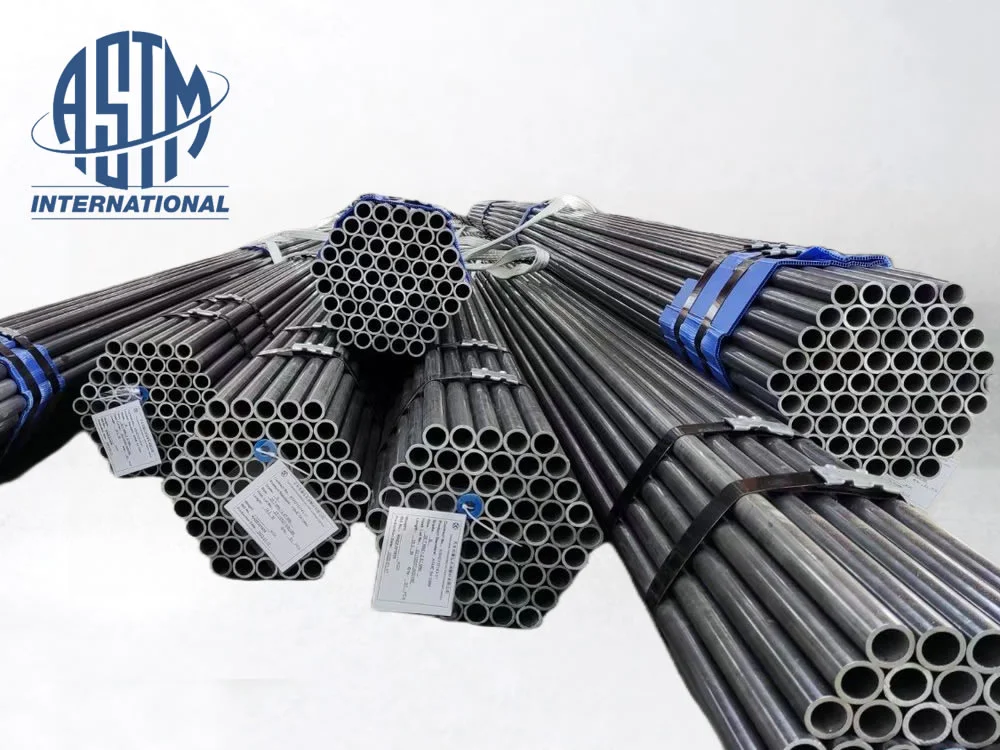

Astm seamless pipes offer high strength, corrosion...

Din en steel pipes offer seamless and welded solut...

High-quality steel pipes manufactured to Chinese G...

Jis seamless pipes, compliant with japanese indust...

Carbon steel seamless pipes offer high strength an...