EFW Pipe (Electric Fusion Welded Pipe) is a high-quality welded steel pipe produced using electric fusion welding, a process that employs electric arcs or electron beams to create strong, reliable welds. Designed for high-pressure and corrosive environments, EFW pipes are widely used in industries like oil and gas, petrochemical, and power generation, meeting standards such as ASTM A312, ASME B36.10, and API 5L.

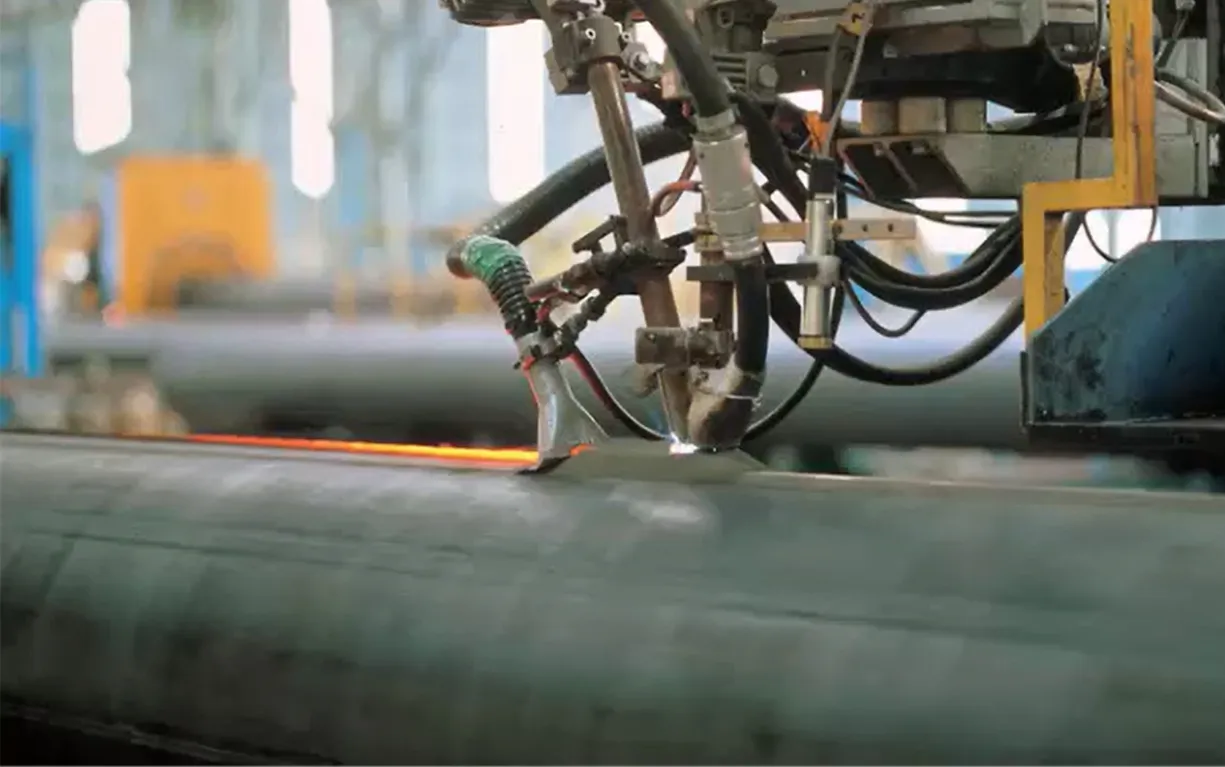

The manufacturing process involves forming steel plates or coils into a cylindrical shape, followed by welding the longitudinal seam using electric fusion techniques, often with filler material. The weld is smoothed using scarfing blades, and post-weld heat treatment may be applied to enhance strength and reduce residual stresses. EFW pipes are available in diameters from 6 inches to 100 inches (152 mm to 2540 mm) and wall thicknesses from Schedule 10 to Schedule 160, offering versatility for various project requirements.

EFW pipes undergo rigorous quality control, including ultrasonic, hydrostatic, and X-ray testing, to ensure defect-free welds and compliance with industry standards. Protective coatings such as 3LPE, Fusion Bonded Epoxy (FBE), or galvanizing enhance corrosion-resistant EFW pipe performance in harsh environments like offshore pipelines or chemical processing plants. Their ability to handle high pressures and corrosive fluids makes them a cost-effective alternative to seamless pipes.

Compared to Electric Resistance Welded (ERW) or Double Submerged Arc Welded (DSAW) pipes, EFW pipes excel in applications requiring thick walls and corrosion resistance, particularly when made from stainless steel (e.g., 304, 316L) or high-nickel alloys. The precise welding process ensures minimal deformation, maintaining dimensional accuracy and structural integrity for critical piping systems.

EFW pipes address challenges like corrosion, high pressure, and thermal stress, making them a reliable choice for engineers seeking durable industrial piping solutions. Their high weld quality and material versatility ensure long-term performance in demanding applications across oil, gas, and chemical industries.

Chemical Composition of EFW Pipes (Typical Grades)

Chemical Composition of API 5L Grade B, ASTM A312 Grade 304, and ASTM A671| Grade | C (% max) | Si (% max) | Mn (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) |

|---|

| API 5L Grade B | 0.28 | 0.45 | 1.20 | 0.03 | 0.03 | - | - |

| ASTM A312 Grade 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-11.0 |

| ASTM A671 | 0.24 | 0.13-0.45 | 0.98 | 0.035 | 0.035 | - | - |

The chemical composition ensures weldability, strength, and corrosion resistance for EFW pipe in demanding applications.

Mechanical Properties of EFW Pipes (Typical Grades)

Mechanical Properties of API 5L Grade B, ASTM A312 Grade 304, and ASTM A671| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|

| API 5L Grade B | 415 | 245 | 23 |

| ASTM A312 Grade 304 | 515 | 205 | 40 |

| ASTM A671 | 450 | 240 | 22 |

These properties ensure EFW pipes provide reliable performance in high-pressure and corrosive environments.

Comparison with Other Welded Pipes

EFW Pipes offer distinct advantages over ERW and DSAW pipes, particularly in high-pressure and corrosive applications. Below is a comparison of key features.

Comparison of EFW Pipes with ERW and DSAW Pipes| Feature | EFW Pipe | ERW Pipe | DSAW Pipe |

|---|

| Welding Process | Electric Fusion Welding (arc/electron beam) | Electric Resistance Welding | Double Submerged Arc Welding |

| Diameter Range | 6–100 inches | 1/8–24 inches | 4–167 inches |

| Wall Thickness | Sch 10–160 | 1.5–20 mm | 2.1–100 mm |

| Applications | High-pressure, corrosive environments | Low to medium-pressure systems | Oil/gas pipelines, structural piles |

| Weld Quality | High (deep penetration) | Moderate | High (100% penetration) |

| Cost | Moderate to high | Lower | Higher |

Why Choose EFW Pipes? Their high weld strength, corrosion resistance, and suitability for thick-walled applications make them ideal for critical industries compared to ERW or DSAW pipes.

ASTM and API Steel Pipe Standards Overview| Standard | Grades | Applications | Characteristics |

|---|

| ASTM A358 | 304, 304L, 316, 316L, and other stainless steel grades. | Chemical processing, food processing, marine environments. | High corrosion resistance for welded stainless steel pipes. |

| ASTM A671 | CA55, CB60, CB65, CB70, and other carbon steel grades. | Low-temperature environments like cryogenic systems. | Toughness and reliability in sub-zero conditions. |

| ASTM A672 | A45, A50, B60, B65, B70, and other carbon/alloy steel grades. | Medium-temperature systems like power generation. | Balances strength and ductility for moderate temperatures. |

| ASTM A691 | CM65, CM70, CM75, and other alloy steel grades. | High-pressure systems like boilers and pressure vessels. | Enhanced strength for high-pressure conditions. |

| API 5L | Grade B, X42, X52, X60, X65, X70, and other carbon steel grades. | Long-distance oil and gas pipelines. | High strength and durability, with increasing yield strength by grade. |

Key Benefits

Superior Weld Strength

Electric fusion welding ensures robust, reliable joints.

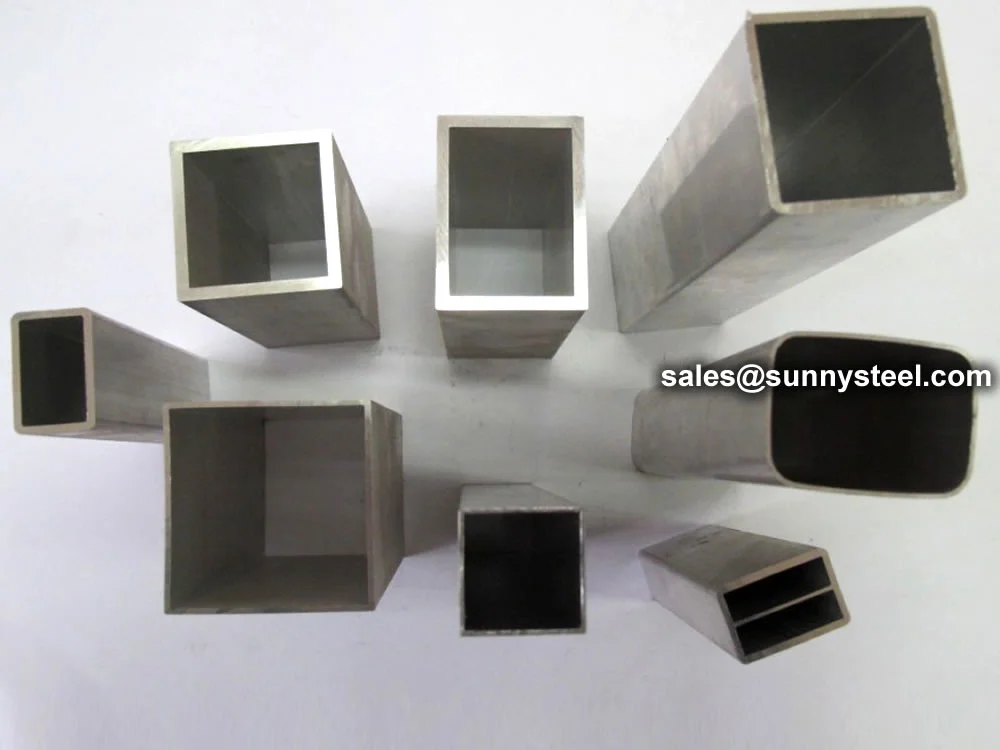

Wide Size Range

Available from 6 to 100 inches for diverse projects.

Corrosion Resistance

Enhanced by 3LPE, FBE, or stainless steel materials.

High Pressure Capability

Ideal for high-pressure pipelines and systems.

Dimensional Accuracy

Precise manufacturing for seamless installation.

Standards Compliance

Meets ASTM A312, ASME B36.10, and API 5L standards.