ERW Pipe

Cost-effective Welded Pipe For Versatile Applications

Erw pipe offers cost-effective, high-quality solutions for oil, gas, and water pipelines, ensuring durability and precision in medium-pressure applications.

Cost-effective Welded Pipe For Versatile Applications

Erw pipe offers cost-effective, high-quality solutions for oil, gas, and water pipelines, ensuring durability and precision in medium-pressure applications.

ERW Pipe

Electric Resistance Welded (ERW) pipes are high-quality welded steel pipes produced using high-frequency electric currents, ideal for medium to low-pressure applications in various industries.

ERW pipes are manufactured by forming steel coils into a cylindrical shape, with edges heated and fused using high-frequency electric resistance welding, eliminating the need for filler material. The weld seam is normalized to ensure uniformity and strength. Available in diameters from 1/8 inch to 24 inches (3 mm to 610 mm) and wall thicknesses from 1.5 mm to 20 mm, they meet standards like API 5L, ASTM A53, and ASME B36.10, suitable for oil and gas, water transmission, and construction.

Rigorous testing, including ultrasonic, hydrostatic, and flattening tests, ensures weld integrity. Protective coatings like galvanizing, 3LPE, or Fusion Bonded Epoxy (FBE) enhance corrosion resistance for applications in water pipelines or chemical plants. Compared to EFW or DSAW pipes, ERW pipes are more economical, ideal for smaller diameters and thinner walls, and available in carbon steel (e.g., API 5L Grade B) and stainless steel grades.

ERW pipes offer cost-effectiveness and high weld quality, making them a reliable choice for water supply lines, structural frameworks, and industrial piping systems.

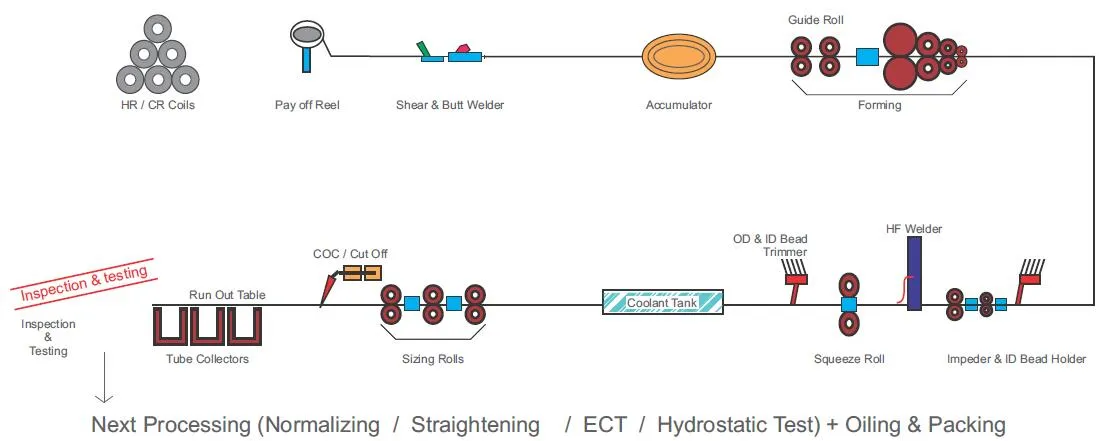

ERW Pipe and Tube Production Process

Electric Resistance Welded (ERW) pipes and tubes are manufactured through a precise process involving high-frequency welding, ensuring durability and quality for various industrial applications.

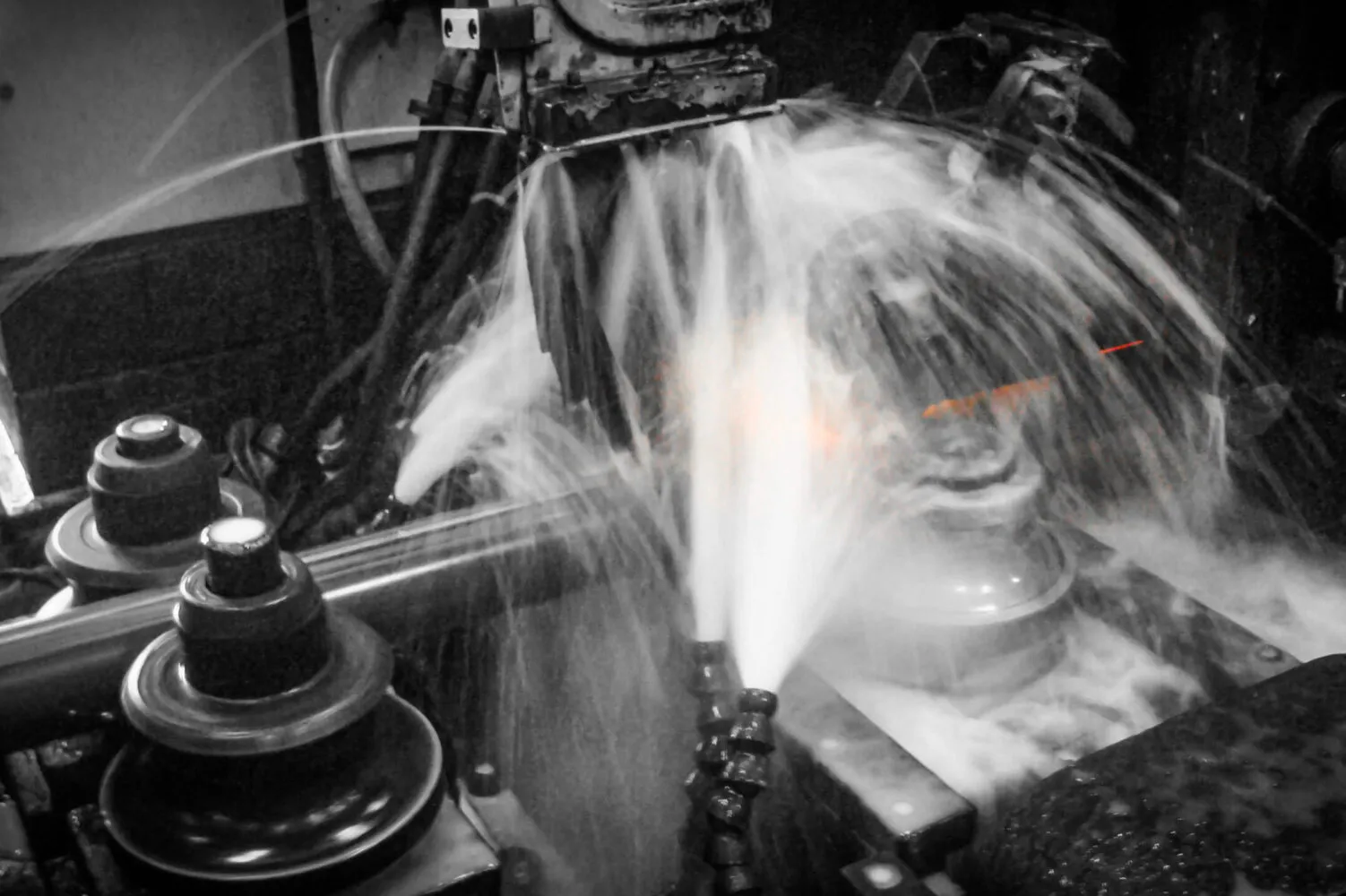

The diligent process of ERW pipe and tube production starts by slitting a Hot-Rolled Steel Coil into narrow strips suitable for pipe formation. These strips are uncoiled, welded, and shaped into a tube via forming rollers. The longitudinal edges of this cylindrical tube are fused using high-frequency electric resistance welding, creating a seamless seam.

Depending on needs, some pipes are annealed to improve mechanical properties. They are cooled, sized to specification, cut to length, and given a surface finish – like oiling, painting, or galvanizing – and an end finish – such as bevelling or threading, before being bundled for shipping.

The meticulous ERW production process delivers cost-effective, durable pipes with reliable weld integrity, ideal for a wide range of industrial and structural applications.

Strategies to Enhance Electric Resistance Welded Pipe Quality

From the analysis data of ERW steel pipe scrapping, it can be seen that the roll adjustment process plays a very important role in the production of welded pipes.

In short, during the welding process of the welded pipe, when the welder is running at a low speed, the welder must pay close attention to the rotation of the rollers of each part of the welded pipe, and adjust the rollers at any time. Ensure that the welding quality and process size of the welded pipe meet the specification requirements.

ERW Mill Tension Roll

ERW Mill Welding Squeezing Roll

ERW Pipe Mill Cleaning Burr

Cutting

Electrical Resistance Welding

Large Steel Pipe Welding

The quality assessment process for Electric Resistance Welded (ERW) pipes includes online non-destructive testing, metallographic inspection, destructive tests (flattening and flaring), and hydrostatic testing.

The detection arm of the rotary flaw detection station is positioned on the longitudinal welded pipe production line. The weld seam is observed via a camera, and the probe's position is adjusted using an operating lever to align the weld seam with the laser, saving the parameters. The steel strip coil number is input through DATASERVR and DACQ computers. The waveform display on the flaw detection interface is monitored. If the waveform exceeds the alarm line, it is compared with thickness measurement data to determine if it is a defect or interference signal. A visual check confirms if the pipeline waveform exceeds the alarm line, triggering an alarm. If an alarm occurs, the process is halted, and welding parameters are readjusted.

Evaluate whether the coarse structure in the heat-affected zone of the weld is eliminated post-heat treatment, ensuring it aligns with the base metal's structure. Check for the absence of inclusions or microcracks in the weld and verify a clear organizational structure, indicating a quality weld mesh.

In high-frequency welding, the proximity and skin effects cause the strip edges to reach a molten or semi-molten state. Under the squeeze roller's pressure, the weld metal flows, forming a streamline angle (α) of 40° to 70° with the base metal on both sides. If the angle exceeds this range, welding process parameters must be adjusted.

Cut a 100mm section of welded pipe and place it under a hydraulic press, with the weld seam perpendicular to the press direction. Press down until the pipe is compressed to 3/4 of its diameter. Inspect the weld for cracks. If no cracks are present, the weld passes; otherwise, adjust welding parameters.

Cut a 100mm section of welded pipe and place it on a conical top core under an oil press. Press down until the flaring reaches 8%. Check the weld for cracks. If no cracks are present, the weld passes; otherwise, adjust welding parameters.

Seal both ends of the welded pipe with flanges, inject water, and gradually increase pressure to the required standard. After holding for a specified duration, visually inspect the weld seam for leaks. If no leaks are detected, the weld passes; otherwise, adjust welding parameters. This is the final step in the quality inspection process.

| Grade | C (% max) | Si (% max) | Mn (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) |

|---|---|---|---|---|---|---|---|

| API 5L Grade B | 0.28 | 0.45 | 1.20 | 0.03 | 0.03 | - | - |

| ASTM A53 Grade B | 0.30 | - | 1.20 | 0.05 | 0.045 | - | - |

| ASTM A312 Grade 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-11.0 |

These standards ensure the mechanical properties and chemical composition of the pipes, providing strength and durability for various applications.

| Parameters | Metric | Imperial |

|---|---|---|

| Rounds | 21.3 to 323.9 mm | 0.50 to 12.00" |

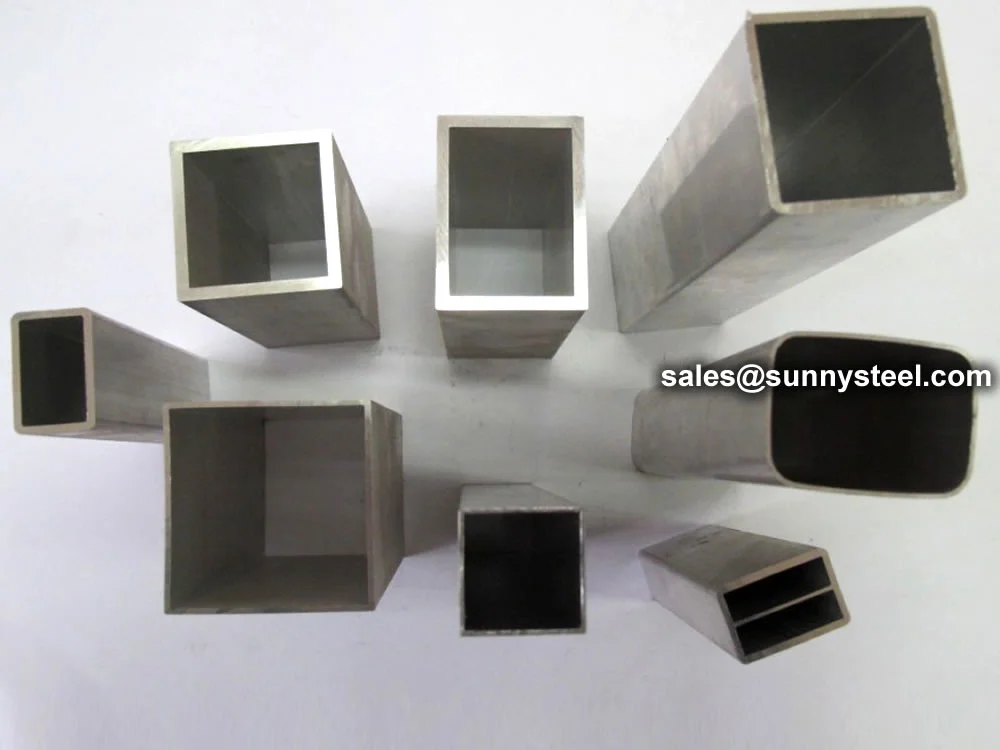

| Squares | 19x19 to 250x250 mm | 1x1 to 10x10" |

| Rectangles | 40x20 to 300x200 mm | 2x1 to 12x8" |

| Thickness | 1.0 to 12.7 mm | 0.0394 to 0.500" |

| Length | 3.0 to 18.3 m | 10 to 60' |

| Surface Finish | Bare, Oiled, Painted, Galvanized | |

| Edge Finish | Plain Ends, Bevelled, Grooved, Swaged, Threaded, Threaded and Coupled | |

| Annual Capacity (Pipe Making) | 410,000 tons | 903,895,275 lbs |

| Annual Capacity (Galvanizing) | 40,000 tons | 88,184,904 lbs |

| Feature | ERW Pipe | EFW Pipe | DSAW Pipe |

|---|---|---|---|

| Welding Process | Electric Resistance Welding | Electric Fusion Welding (arc/electron beam) | Double Submerged Arc Welding |

| Diameter Range | 1/8–24 inches | 6–100 inches | 4–167 inches |

| Wall Thickness | 1.5–20 mm | Sch 10–160 | 2.1–100 mm |

| Applications | Water, gas, low to medium-pressure systems | High-pressure, corrosive environments | Oil/gas pipelines, structural piles |

| Weld Quality | Moderate | High (deep penetration) | High (100% penetration) |

| Cost | Lower | Moderate to high | Higher |

ERW Pipes are cost-effective and versatile compared to EFW and DSAW pipes, particularly for smaller diameters and thinner walls. Below is a comparison of key features.

| Standard | Applications | Characteristics |

|---|---|---|

| API 5L | Gas and water transport in the oil and gas industry, including seamless and welded steel pipes with common ports, pipe socket ports, direct stream tubes (TFL), and specialized connection tubes. | High strength and durability for long-distance pipelines. |

| ASTM A53 B | Mechanical and pressure applications, suitable for steam, water, gas, and air lines. | Versatile for general-purpose piping with good weldability. |

| ASTM A178 | Minimum-wall-thickness ERW tubes made of carbon steel and carbon-manganese steel for boiler tubes, boiler flues, superheater flues, and safe ends. | Designed for high-temperature boiler applications. |

| ASTM A500/501 | Cold-formed welded and seamless carbon steel round, square, rectangular, or special-shape structural tubing for bridges, buildings, and general structural purposes. | Suitable for welded, riveted, or bolted construction. |

| ASTM A691 | Carbon and alloy steel pipes, electric-fusion-welded with filler metal, for high-pressure service at high temperatures. | High strength for pressure vessels and high-temperature environments. |

| ASTM A252 | Nominal wall cylindrical steel pipe piles, used as load-carrying members or shells for cast-in-place concrete piles. | Robust for structural pile applications. |

| ASTM A672 | Electric-fusion-welded steel pipe for high-pressure service at moderate temperatures. | Balances strength and ductility for moderate-temperature systems. |

| Specifications | Steel Grades |

|---|---|

| ASTM A-210 / ASME SA-210 | Gr. A1; C |

| BS 3059-1 | Gr. 320 |

| BS 3059-2 | Gr. 360; 440; 620; 622 |

| EN 17175 | 16Mo3 |

| EN 10216/1 | P235TR1; P235TR2; P265TR1; P265TR2 |

| EN 10216/2 | P235GHTC1; P235GHTC2; P265GHTC1; P265GHTC2 |

| ASTM A-209 ASTM A-213 ASME SA-213 |

Gr. T1; T11; T12; T22; T5; T9; T91; T92 |

| ASTM A-335 / ASME SA-335 | Gr. P1; P11; P12; P22; P5; P9; P91; P92 |

ERW Pipes provide cost-effective, versatile solutions for critical applications across construction, mining, and industrial sectors. Their high weld quality and wide size range make them ideal for bearing piles, structural sections, and more, ensuring durability in demanding environments.

Used in deep foundations to transfer loads to stronger soil layers, resisting loads via skin friction and point bearing.

Paired with sheet piles in combi-walls to handle high bending loads in retaining structures.

Symmetrical design resists buckling in long, unsupported structural applications.

Supports small-diameter piles for foundation support, seismic retrofits, and slope stabilization.

Resists bending loads in sign poles, towers, and transmission lines with customizable sizes.

Used in vertical shafts for personnel, equipment, and air, with prepped ends for splicing.

Transports crude oil and refined products in medium-pressure pipelines.

Supports natural gas transportation in pipelines.

Used in urban and agricultural water supply systems.

Why Choose ERW Pipes? Their cost-effectiveness, high weld quality, and versatility make ERW pipes ideal for construction, mining, oil, gas, and water transmission applications, ensuring reliable performance.

Hfi pipe offers high-quality, cost-effective solut...

Anti-corrosion steel pipes provide robust protecti...

Jcoe pipe offers high-strength, large-diameter sol...

Dsaw pipe offers high-strength, durable solutions ...

special welded tubes are engineered to meet specif...

Ssaw pipe offers cost-effective, large-diameter so...