HFI Pipe (High-Frequency Induction Welded Pipe) is a premium welded steel pipe manufactured using high-frequency induction welding, a process that employs electromagnetic induction to heat and fuse steel edges. Known for its superior weld quality and efficiency, HFI pipes are widely used in industries such as oil and gas, construction, and water transmission, meeting standards like API 5L, ASTM A53, and ASME B36.10.

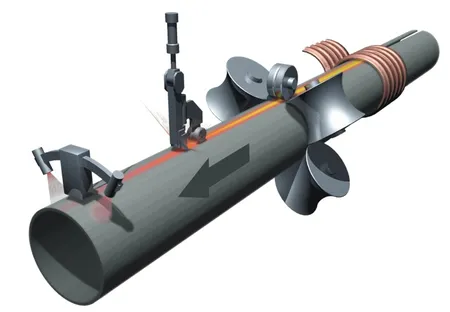

The manufacturing process involves forming steel coils into a cylindrical shape, with the edges heated by high-frequency induction currents and pressed together to form a strong, seamless weld without filler material. The weld seam is normalized to ensure uniformity and strength. HFI pipes are available in diameters from 1/8 inch to 24 inches (3 mm to 610 mm) and wall thicknesses from 1.5 mm to 20 mm, offering versatility for various project requirements.

HFI pipes undergo stringent testing, including ultrasonic, hydrostatic, and flattening tests, to ensure weld integrity and compliance with industry standards. Protective coatings such as galvanizing, 3LPE, or Fusion Bonded Epoxy (FBE) enhance corrosion-resistant HFI pipe performance in harsh environments like oil pipelines or water systems. Their high production efficiency and consistent weld quality make them a cost-effective choice for large-scale projects.

Compared to Electric Resistance Welded (ERW) or Electric Fusion Welded (EFW) pipes, HFI pipes offer improved weld consistency due to the induction heating process, making them ideal for applications requiring high precision and reliability. Available in carbon steel (e.g., API 5L Grade B, ASTM A53 Grade B) and stainless steel grades, they provide flexibility for diverse applications, including structural and fluid transport systems.

HFI pipes address challenges like corrosion, mechanical stress, and buckling, making them a reliable choice for engineers seeking high-quality industrial piping solutions. Their precision manufacturing and adaptability ensure durability in oil and gas pipelines, construction, and mining applications.