JCOE Pipe (Longitudinal Submerged Arc Welded Pipe) is a high-strength, large-diameter

steel pipe produced using the JCOE (J-ing, C-ing, O-ing, Expanding) process. Renowned for its precision and

robustness, JCOE pipes are widely used in gas transport, oil pipelines, hot-water pipes, potable

water distribution, sewer piping, and construction projects, meeting standards like API 5L, ASTM A671, and

GB/T3091-2008.

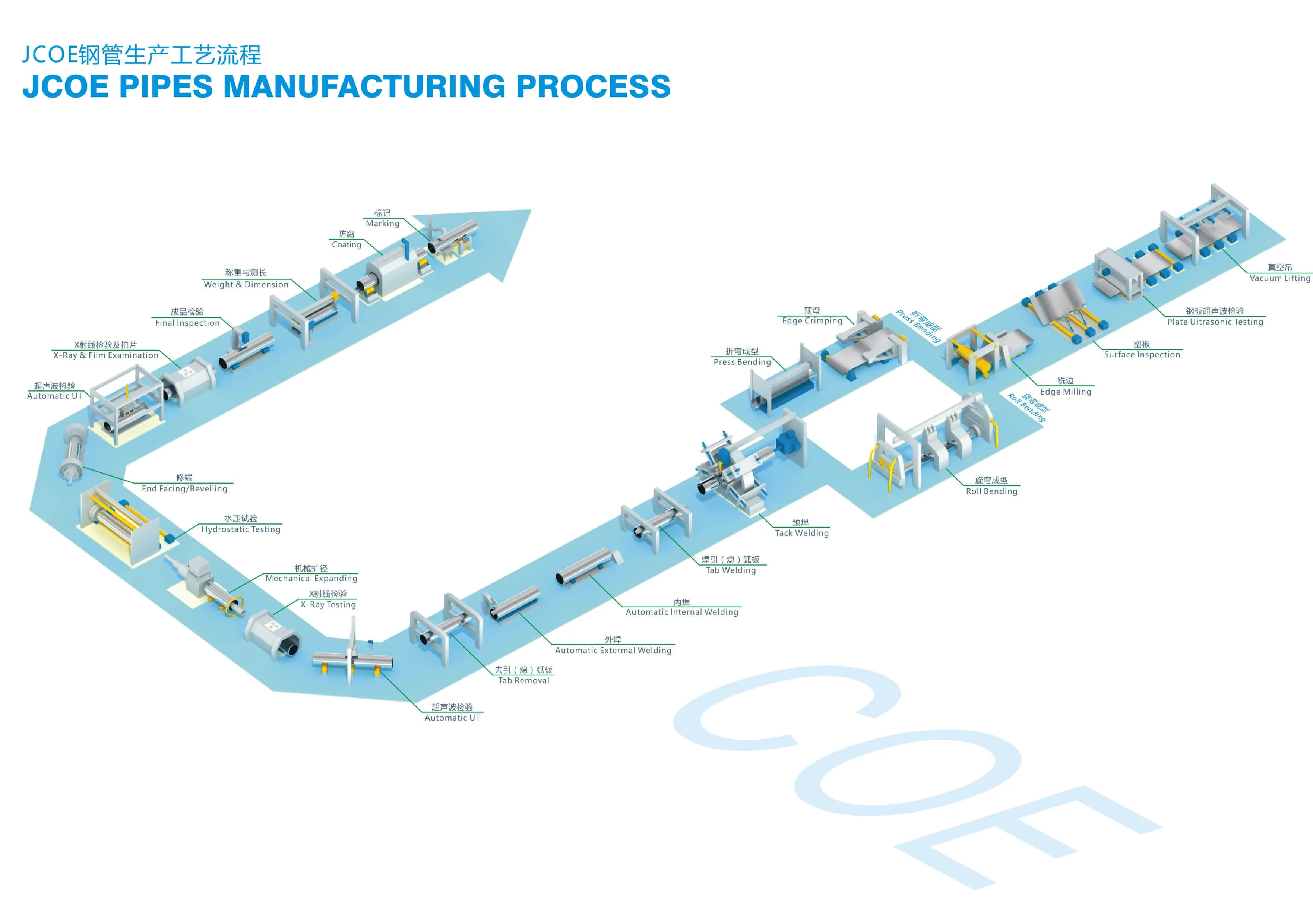

The JCOE process involves shaping steel plates through progressive pressing into J, C, and O forms, followed by

double-sided submerged arc welding (SAW) and cold expansion to ensure dimensional accuracy and stress relief.

Available in diameters from 16 to 72 inches (406–1829 mm) and wall thicknesses from 6.0 to 25.4 mm, JCOE

pipes are designed for high-pressure and large-scale applications. Protective coatings like 3LPE or FBE

enhance corrosion-resistant JCOE pipe performance in harsh environments.

JCOE pipes undergo rigorous testing, including ultrasonic, hydrostatic, and X-ray inspections, to

ensure weld integrity and compliance with industry standards. The process’s flexibility supports both high-volume

and small-batch production, making it cost-effective for diverse project requirements, from urban water systems to

offshore oil pipelines.

Compared to UOE or SSAW pipes, JCOE pipes offer a balance of cost-efficiency and high-quality

welds, making them ideal for medium to large-scale infrastructure projects. Their uniform deformation and robust

construction ensure reliability in demanding applications like gas transport and sewer systems.

JCOE pipes address challenges such as corrosion, high pressure, and structural demands, providing

engineers with dependable large-diameter JCOE pipe solutions for critical infrastructure, ensuring

safety and longevity.

Chemical Composition of API 5L Grade B, Q345, and ASTM A671 CC60

| Grade |

C (% max) |

Si (% max) |

Mn (% max) |

P (% max) |

S (% max) |

Cr (% max) |

| API 5L Grade B |

0.28 |

0.45 |

1.20 |

0.03 |

0.03 |

- |

| Q345 |

0.20 |

0.50 |

1.70 |

0.035 |

0.035 |

0.30 |

| ASTM A671 CC60 |

0.21 |

0.13-0.45 |

0.55-1.30 |

0.035 |

0.035 |

- |

The chemical composition ensures weldability, strength, and corrosion resistance for JCOE

pipe in demanding applications.

Mechanical Properties of API 5L Grade B, Q345, and ASTM A671 CC60

| Grade |

Tensile Strength (MPa min) |

Yield Strength (MPa min) |

Elongation (% min) |

| API 5L Grade B |

415 |

245 |

23 |

| Q345 |

470 |

345 |

21 |

| ASTM A671 CC60 |

415 |

220 |

25 |

These properties ensure JCOE pipes provide robust performance in high-pressure and structural

applications.

Comparison of JCOE Pipes with UOE and SSAW Pipes

| Feature |

JCOE Pipe |

UOE Pipe |

SSAW Pipe |

| Forming Process |

J-C-O-E (Progressive Multi-Step) |

U-O-E (Three-Step) |

Spiral Welding |

| Diameter Range |

16–72 inches |

20–44 inches |

20–100 inches |

| Wall Thickness |

6.0–25.4 mm |

6.4–25.4 mm |

5.0–25.4 mm |

| Applications |

Gas, oil, water, sewer, construction |

Offshore pipelines, high-pressure |

Water, low-pressure |

| Weld Quality |

High (Double-Sided SAW) |

Very High |

Moderate (Spiral Weld) |

| Cost |

Moderate |

High |

Low |

Why Choose JCOE Pipes? Their cost-efficiency, high weld quality, and flexibility make them ideal

for gas, oil, water, sewer, and construction applications.

Key Benefits

Superior Weld Quality

Double-sided SAW ensures strong, reliable joints.

Large Diameter Range

Available from 16 to 72 inches for diverse projects.

Corrosion Resistance

3LPE or FBE coatings protect against harsh environments.

Production Flexibility

Supports small-batch and multi-specification production.

Dimensional Precision

Cold expansion ensures accurate sizing and straightness.

Standards Compliance

Meets API 5L, ASTM A671, and GB/T3091-2008 standards.