In LSAW pipe mills, processing is done by cold forming of heavy carbon steel plates. Among the available

forming processes, we focuses on the JCO technology. We supply the equipment for all important process steps

from plate preparation to forming, welding, testing, and finishing. Including not only the core machines,

but also all the upstream and downstream process steps required for the production of large-diameter pipes.

Our plants stand for high product quality at medium to high output, flexible and cost-effective processes,

precise dimensions, and close pipe tolerances.

LSAW Pipe (Longitudinal Submerged Arc Welded Pipe) is a high-strength, large-diameter steel

pipe manufactured using longitudinal submerged arc welding, often through processes like JCOE or UOE.

Renowned for its precision and durability, LSAW pipes are ideal for oil and gas pipelines,

construction, water supply, and petrochemical applications, meeting standards such as API 5L, ASTM A671, and

GB/T3091-2008.

The manufacturing process involves forming steel plates into a cylindrical shape using methods like JCOE

(J-ing, C-ing, O-ing, Expanding) or UOE, followed by double-sided submerged arc welding (SAW) to create a

robust longitudinal seam. Cold expansion ensures dimensional accuracy and stress relief. Available in

diameters from 16 to 72 inches (406–1829 mm) and wall thicknesses from 6.0 to 40.0 mm, LSAW

pipes are designed for high-pressure and large-scale projects.

LSAW pipes undergo rigorous testing, including ultrasonic, hydrostatic, and X-ray

inspections, to ensure weld integrity and compliance with industry standards. Protective coatings like 3LPE

or FBE enhance corrosion-resistant LSAW pipe performance in harsh environments, such as

offshore pipelines or petrochemical facilities. The process supports high-volume production while

maintaining precision for critical applications.

Compared to SSAW or ERW pipes, LSAW pipes offer superior weld quality and strength, making

them a preferred choice for high-pressure applications like oil and gas transport. Their ability to handle

large diameters and thick walls ensures reliability in structural and fluid transport systems.

LSAW pipes address challenges such as corrosion, high pressure, and structural demands,

providing engineers with dependable large-diameter LSAW pipe solutions for critical

infrastructure, ensuring safety and longevity in demanding environments.

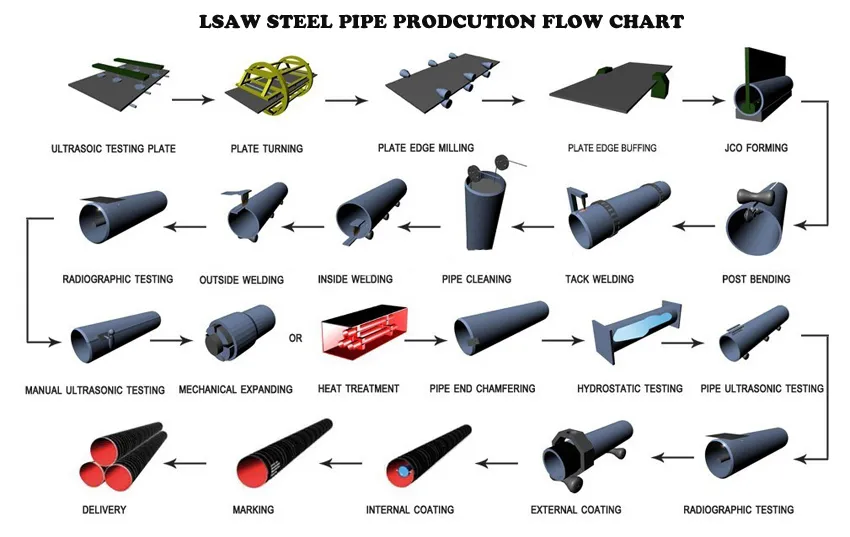

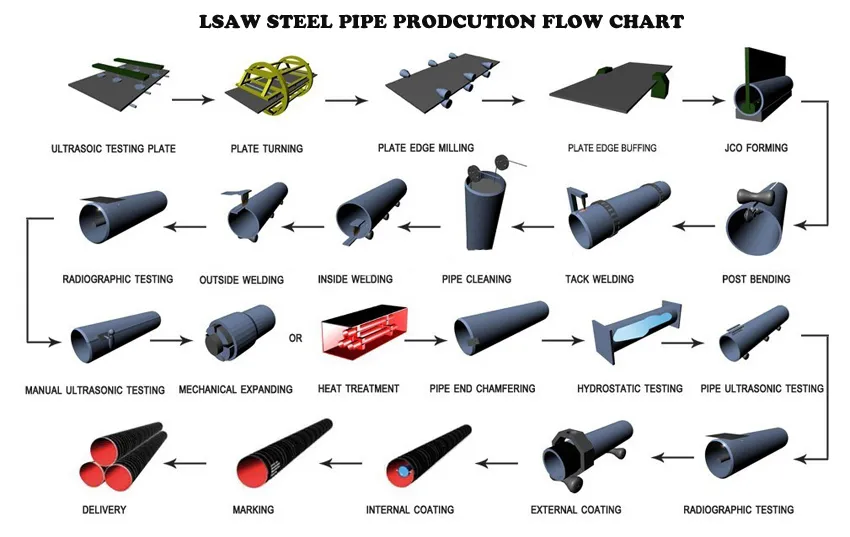

LSAW Pipe Manufacturing Process

Longitudinal Submerged Arc Welded (LSAW) pipes are produced through a precise process, ensuring durability and reliability for demanding industrial applications.

The process begins with uncoiling and leveling a steel coil, followed by trimming to the required size. The steel strip is formed into a cylindrical shape through bending operations, then welded using submerged arc welding, where a continuous electrical arc melts the plate edges under a granular flux shield to create a high-quality longitudinal seam. This ensures a clean and efficient weld for robust performance.

For UOE LSAW pipes, the welded pipe undergoes U-ing, O-ing, and expansion to achieve precise dimensions and mechanical properties. Similarly, JCOE LSAW pipes involve J-ing, C-ing, O-ing, and expansion for enhanced shaping and strength. Final steps include inspection, testing (e.g., ultrasonic, hydrostatic), and coating (e.g., 3LPE, FBE) to ensure compliance with standards like API 5L, ASTM A671, and GB/T3091-2008, guaranteeing longevity in oil, gas, water, and petrochemical applications.

The meticulous LSAW manufacturing process delivers high-strength, large-diameter pipes, ideal for critical infrastructure projects requiring precision and durability.

Steel Standards: Chemical Composition and Mechanical Properties

| Standard |

Grade |

Chemical Composition (max)% |

Mechanical Properties (min) |

| C |

Mn |

Si |

S |

P |

Yield Strength |

Tensile Strength |

| (Mpa) |

(Mpa) |

| GB/T700-2006 |

A |

0.22 |

1.4 |

0.35 |

0.05 |

0.045 |

235 |

370 |

| B |

0.2 |

1.4 |

0.35 |

0.045 |

0.045 |

235 |

370 |

| C |

0.17 |

1.4 |

0.35 |

0.04 |

0.04 |

235 |

370 |

| D |

0.17 |

1.4 |

0.35 |

0.035 |

0.035 |

235 |

370 |

| GB/T1591-2009 |

A |

0.2 |

1.7 |

0.5 |

0.035 |

0.035 |

345 |

470 |

| B |

0.2 |

1.7 |

0.5 |

0.03 |

0.03 |

345 |

470 |

| C |

0.2 |

1.7 |

0.5 |

0.03 |

0.03 |

345 |

470 |

| BS En10025 |

S235JR |

0.17 |

1.4 |

- |

0.035 |

0.035 |

235 |

360 |

| S275JR |

0.21 |

1.5 |

- |

0.035 |

0.035 |

275 |

410 |

| S355JR |

0.24 |

1.6 |

- |

0.035 |

0.035 |

355 |

470 |

| DIN 17100 |

ST37-2 |

0.2 |

- |

- |

0.05 |

0.05 |

225 |

340 |

| ST44-2 |

0.21 |

- |

- |

0.05 |

0.05 |

265 |

410 |

| ST52-3 |

0.2 |

1.6 |

0.55 |

0.04 |

0.04 |

345 |

490 |

| JIS G3101 |

SS400 |

- |

- |

- |

0.05 |

0.05 |

235 |

400 |

| SS490 |

- |

- |

- |

0.05 |

0.05 |

275 |

490 |

| API 5L PSL1 |

A |

0.22 |

0.9 |

- |

0.03 |

0.03 |

210 |

335 |

| B |

0.26 |

1.2 |

- |

0.03 |

0.03 |

245 |

415 |

| X42 |

0.26 |

1.3 |

- |

0.03 |

0.03 |

290 |

415 |

| X46 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

320 |

435 |

| X52 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

360 |

460 |

| X56 |

0.26 |

1.1 |

- |

0.03 |

0.03 |

390 |

490 |

| X60 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

415 |

520 |

| X65 |

0.26 |

1.45 |

- |

0.03 |

0.03 |

450 |

535 |

| X70 |

0.26 |

1.65 |

- |

0.03 |

0.03 |

585 |

570 |

The chemical composition ensures weldability, strength, and corrosion resistance for

LSAW pipe in demanding applications.

Tolerance of Outside Diameter and Wall Thickness

| Types |

Standard |

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

| Tube end OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

| Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm<T<15.0mm, ±0.11mm |

| D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

HQW11s-120X3200 Technical Parameters

| Number |

Technical Parameter |

Unit |

HQW11s-120X3200 |

| 1 |

Material yield limit |

Mpa |

245 |

345 |

345 |

| 2 |

Wall thickness |

mm |

120 |

100 |

110 |

| 3 |

Maximum pre-bending thickness |

mm |

110 |

90 |

100 |

| 4 |

Maximum width of steel plate |

mm |

3200 |

3200 |

3200 |

| 5 |

Minimum diameter of fully loaded rolling steel plate |

mm |

2500 |

1600 |

1600 |

LSAW Pipes offer superior strength and weld quality compared to SSAW and ERW pipes,

making them ideal for large-diameter, high-pressure applications. Below is a comparison of key features.

Key Benefits

Superior Weld Quality

Double-sided SAW ensures robust, reliable joints.

Large Diameter Range

Available from 16 to 72 inches for diverse projects.

Corrosion Resistance

3LPE or FBE coatings protect against harsh environments.

High Strength

Handles high-pressure and structural demands effectively.

Dimensional Precision

Cold expansion ensures accurate sizing and straightness.

Standards Compliance

Meets API 5L, ASTM A671, and GB/T3091-2008 standards.