Size Range and Specifications of

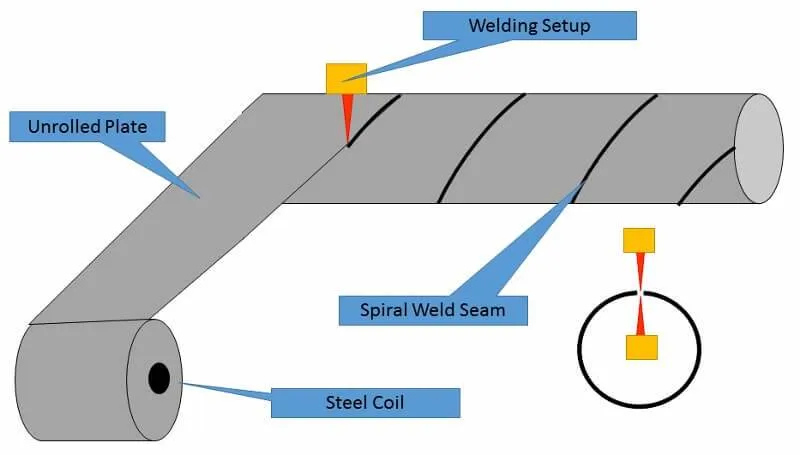

SAW Pipe

Submerged Arc Welded (SAW) pipes are manufactured in a wide range of sizes and grades, tailored to meet diverse industrial standards and customer requirements.

SAW pipes are available with an outer diameter of 219–3200 mm, wall thickness of 5–30 mm, and lengths up to 12,000 mm + 500 mm. They comply with standards such as ASTM A252-89, API SPEC 5L, GB/T9711.1, and SY/T5037, using materials like Q235-Q345, L175-L485, SS400, 16Mn, and L290-L360, or customized per customer needs. Specific tolerances, mechanical, and chemical properties can be tailored on request.

Protective coatings, including HDPE, 3PE, 3PP, and pipe cement mortar lining, enhance corrosion resistance for applications in oil and gas, water transport, and construction. Quality is ensured through Mill Test Certificates (EN 10204/3.1B) and third-party inspections by SGS, BV, or Lloyds, guaranteeing reliable performance in demanding environments.

In addition to above specification, the pipes can be produced according to customer’s requirements.

- Mill Test Certificate: EN 10204/3.1B

- Third party inspection: SGS, BV, Lloyds etc.

SAW pipes offer versatile sizing and robust quality, making them ideal for critical infrastructure projects requiring durability and customization.