SSAW Pipe (Spiral Submerged Arc Welded Pipe) is a high-strength, large-diameter steel pipe

manufactured by spirally welding steel coils using submerged arc welding. Known for its cost-effectiveness

and versatility, SSAW pipes are widely used in oil and gas pipelines, water transmission,

structural construction, petrochemical industries, piling, and abrasive material transport, meeting

standards like API 5L, ASTM A252, and GB/T9711.

The spiral welding process involves forming steel coils into a helical shape, followed by double-sided

submerged arc welding to create a continuous spiral seam. This method allows for larger diameters (up to 100

inches or 2540 mm) and wall thicknesses from 5.0 to 25.4 mm, making SSAW pipes ideal for

low to medium-pressure applications and large-scale projects. Protective coatings like 3LPE or FBE enhance

corrosion-resistant SSAW pipe performance in harsh environments, such as underwater or

underground systems.

SSAW pipes undergo rigorous testing, including ultrasonic, hydrostatic, and X-ray

inspections, to ensure weld integrity and compliance with industry standards. Their cost-effective

production and ability to handle large diameters make them suitable for water transmission, piling, and

low-pressure fluid transport.

Compared to LSAW or ERW pipes, SSAW pipes offer a cost advantage and greater flexibility in

diameter range, though they are better suited for lower-pressure applications due to the spiral weld. Their

robust construction ensures reliability in structural and fluid transport systems.

SSAW pipes address challenges like corrosion, large-scale fluid transport, and structural

demands, providing engineers with affordable large-diameter SSAW pipe solutions for oil,

gas, water, construction, and petrochemical applications, ensuring efficiency and durability.

SSAW pipes in stock

What Are

SSAW Steel Pipes?

Spiral Submerged Arc Welded (SSAW) steel pipes are produced using double-sided

submerged arc welding, offering cost-effective solutions for large-diameter pipelines.

SSAW pipes are formed by spirally welding narrower sheets or hot-rolled coils, reducing

production costs while enabling large diameters suitable for transporting oil, gas, and

water. The double-sided submerged arc welding process uses a filler wire

and conductive flux to create a robust spiral seam, ensuring strength and reliability for

high-volume fluid transport applications.

SSAW steel pipe, also known as spiral submerged arc welded steel pipe, is a type of steel

pipe made by rolling and welding steel strips in a spiral or helical pattern, resulting in a

spiral weld seam. This manufacturing process allows for the production of large diameter

pipes, making it suitable for various applications, including oil and gas pipelines, water

distribution, and construction.

SSAW pipes combine cost efficiency with durability, making them

ideal for large-scale infrastructure projects requiring large-diameter, high-capacity

pipelines.

Standard

SSAW mill line used for making Grade A, B, ~X70 steel coil with thickness 5.0mm to 25.4mm, width 400mm to

2000 mm into Spiral welding pipe with outer diameter from 219 mm to 3020mm through uncoiling, leveling, edge

milling, forming and welding. The processing can satisfy producing spiral pipes according to standard

API-5L, ASTM A53,GB/T9711-2011.

Steel Pipe Classification, Standards and Main Products

| Classification |

Standard |

Main Products |

| Steel Pipe for

Fluid Service |

GB/T 14291 |

Welded pipe for mine fluid service |

| GB/T 3091 |

Welded pipe for low pressure fluid service |

| SY/T 5037 |

Spirally submerged arc welded steel pipe for pipelines for low

pressure fluid service |

| ASTM A53 |

Black and hot-dipped galvanized welded and seamless steel pipe

|

| BS EN10217-2 |

Welded steel tubes for pressure purposes - delivery technical

conditions - part2: Electric welded non-alloy and alloy steel tubes with specified

elevated temperature properties |

| BS EN10217-5 |

Welded steel tubes for pressure purposes - delivery technical

conditions - part5: submerged arc welded non-alloy and alloy steel tubes with specified

elevated temperature properties |

| Steel Pipe for

Ordinary Structure |

GB/T 13793 |

Longitudinally electric resistance welded steel pipe |

| SY/T 5040 |

Spirally submerged arc welded steel pipe piles |

| ASTM A252 |

Welded and seamless steel pipe piles |

| BS EN10219-1 |

Cold formed welded structural hollow sections of non-alloy and

fine grain steels - part1: Technical delivery conditions |

| BS EN10219-2 |

Cold formed welded structural hollow sections of non-alloy and

fine grain steels - part2: tolerances, dimensions and sectional properties |

| Line Pipe |

GB/T 9711.1 |

Steel pipe for pipeline transportation system of petroleum and

natural gas industries (Class A steel pipe) |

| GB/T 9711.2 |

Steel pipe for pipeline transportation system of petroleum and

natural gas industries (Class B steel pipe) |

| API 5L PSL1/2 |

Line pipe |

| Casing |

API 5CT/ ISO 11960 PSL1 |

Steel pipe for use as casing or tubing for wells of petroleum and

natural gas industries |

The chemical composition ensures weldability, strength, and corrosion resistance for

SAW pipe in demanding applications.

SSAW is not stocked rather can easily be sourced for projects across the below range

| NOMINAL SIZE DN |

IMPERIAL SIZE |

OUTSIDE DIAMETER MM (Ø) |

WALL THICKNESS MM (t) |

TYPE |

LENGTH |

MASS KG/METRE |

| 350 |

14" |

355.6 |

6.4 |

SSAW |

12 |

55.12 |

| 350 |

14" |

355.6 |

9.5 |

SSAW |

9 |

81.09 |

| 350 |

14" |

355.6 |

9.5 |

SSAW |

12 |

81.09 |

| 350 |

14" |

355.6 |

12.7 |

SSAW |

12 |

107.4 |

| 350 |

14" |

355.6 |

15.9 |

SSAW |

12 |

133.2 |

| 350 |

14" |

406.4 |

25.4 |

SSAW |

12 |

206.46 |

| 400 |

16" |

406.4 |

6.4 |

SSAW |

12 |

63.13 |

| 400 |

16" |

406.4 |

9.5 |

SSAW |

12 |

92.99 |

| 400 |

16" |

406.4 |

12.7 |

SSAW |

12 |

123.31 |

| 400 |

16" |

406.4 |

15.9 |

SSAW |

12 |

153.12 |

| 450 |

18" |

457 |

6.4 |

SSAW |

12 |

71.12 |

| 450 |

18" |

457 |

9.5 |

SSAW |

12 |

104.84 |

| 450 |

18" |

457 |

12.7 |

SSAW |

12 |

139.16 |

| 450 |

18" |

457 |

15.9 |

SSAW |

12 |

172.96 |

| 500 |

20" |

508 |

6.4 |

SSAW |

12 |

79.17 |

| 500 |

20" |

508 |

9.5 |

SSAW |

12 |

116.79 |

| 500 |

20" |

508 |

12.7 |

SSAW |

12 |

155.13 |

| 500 |

20" |

508 |

15.9 |

SSAW |

12 |

192.96 |

| 500 |

20" |

508 |

16 |

SSAW |

13 |

194.14 |

| 550 |

22" |

559 |

12.5 |

SSAW |

12 |

168.47 |

| 550 |

22" |

559 |

16 |

SSAW |

12 |

214.26 |

| 600 |

24" |

610 |

6.4 |

SSAW |

12 |

95.27 |

| 600 |

24" |

610 |

9.5 |

SSAW |

12 |

140.69 |

| 600 |

24" |

610 |

12.7 |

SSAW |

12 |

187.07 |

| 600 |

24" |

610 |

15.9 |

SSAW |

12 |

232.96 |

| 600 |

24" |

610 |

17.48 |

SSAW |

12 |

255.43 |

| 600 |

24" |

610 |

20 |

SSAW |

12 |

291.01 |

| 600 |

24" |

610 |

25.4 |

SSAW |

12 |

366.19 |

| 600 |

24" |

610 |

31 |

SSAW |

12 |

442.65 |

| 650 |

26" |

660 |

10 |

SSAW |

12 |

160.3 |

| 650 |

26" |

660 |

12.7 |

SSAW |

12 |

202.74 |

| 650 |

26" |

660 |

20 |

SSAW |

12 |

315.67 |

| 700 |

28" |

711 |

9.5 |

SSAW |

12 |

164.35 |

| 700 |

28" |

711 |

12.7 |

SSAW |

12 |

218.71 |

| 700 |

28" |

711 |

15.9 |

SSAW |

12 |

272.56 |

| 700 |

28" |

711 |

20 |

SSAW |

13 |

340.82 |

| 750 |

30" |

762 |

9.5 |

SSAW |

12 |

176.3 |

| 750 |

30" |

762 |

12.7 |

SSAW |

12 |

234.68 |

| 750 |

30" |

762 |

15.9 |

SSAW |

12 |

292.56 |

| 750 |

30" |

762 |

20 |

SSAW |

12 |

365.9 |

| 800 |

32" |

813 |

9.5 |

SSAW |

12 |

188.25 |

| 800 |

32" |

813 |

12.7 |

SSAW |

12 |

250.66 |

| 800 |

32" |

813 |

16 |

SSAW |

12 |

314.48 |

| 800 |

32" |

813 |

20 |

SSAW |

12 |

391.13 |

| - |

- |

820 |

16 |

SSAW |

11.9 |

317.25 |

| 850 |

34" |

864 |

7.9 |

SSAW |

8 |

166.79 |

| 900 |

36" |

914 |

9.5 |

SSAW |

12 |

211.91 |

| 900 |

36" |

914 |

12.7 |

SSAW |

12 |

282.29 |

| 900 |

36" |

914 |

15.9 |

SSAW |

12 |

352.16 |

| - |

- |

900 |

20 |

SSAW |

12 |

434.04 |

| 900 |

36" |

914 |

20 |

SSAW |

12 |

440.95 |

| 950 |

38" |

965 |

9.5 |

SSAW |

6.2 |

223.86 |

| 1000 |

40" |

1016 |

10 |

SSAW |

12 |

248.09 |

| 1000 |

40" |

1016 |

16 |

SSAW |

12 |

394.58 |

| - |

- |

1032 |

20 |

SSAW |

7.2 |

499.15 |

| 1050 |

42" |

1067 |

9.5 |

SSAW |

12 |

247.76 |

| 1050 |

42" |

1067 |

12.7 |

SSAW |

12 |

330.21 |

| 1050 |

42" |

1067 |

15.9 |

SSAW |

12 |

412.16 |

| 1200 |

48" |

1219 |

9.5 |

SSAW |

12 |

283.37 |

| 1200 |

48" |

1219 |

12.7 |

SSAW |

12 |

377.81 |

| 1200 |

48" |

1219 |

15.9 |

SSAW |

12 |

471.76 |

| 1200 |

48" |

1219 |

20 |

SSAW |

12 |

591.38 |

Note:

Pipes can be sourced conforming to AS/NZS3678 Grade 350 L0 & manufactured to AS/NZS1163 tolerances & to grade C350 L0.

Pipes/piles can be sourced at longer lengths or with piling shoes spliced/welded to AS1554.1.

Chemical Composition and Mechanical Properties of Various Pipe Standards

| Standard |

Grade |

Chemical Composition (max %) |

Mechanical Properties (min) |

| C |

Si |

Mn |

P |

S |

Tensile Strength (MPa) |

Yield Strength (MPa) |

| API 5CT |

H40 |

- |

- |

- |

- |

0.030 |

417 |

417 |

| J55 |

- |

- |

- |

- |

0.030 |

517 |

517 |

| K55 |

- |

- |

- |

- |

0.300 |

655 |

655 |

| API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

| B |

0.26 |

- |

1.20 |

0.030 |

0.030 |

415 |

415 |

| X42 |

0.26 |

- |

1.30 |

0.030 |

0.030 |

415 |

415 |

| X46 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

435 |

435 |

| X52 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

460 |

460 |

| X56 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

490 |

490 |

| X60 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

520 |

520 |

| X65 |

0.26 |

- |

1.45 |

0.030 |

0.030 |

535 |

535 |

| X70 |

0.26 |

- |

1.65 |

0.030 |

0.030 |

570 |

570 |

| API 5L PSL2 |

B |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

415 |

415 |

| X42 |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

415 |

415 |

| X46 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

435 |

435 |

| X52 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

460 |

460 |

| X56 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

490 |

490 |

| X60 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

520 |

520 |

| X65 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

535 |

535 |

| X70 |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

570 |

570 |

| X80 |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

625 |

625 |

| ASTM A53 |

A |

0.25 |

0.10 |

0.95 |

0.050 |

0.045 |

330 |

330 |

| B |

0.30 |

0.10 |

1.20 |

0.050 |

0.045 |

415 |

415 |

| ASTM A252 |

1 |

- |

- |

- |

0.050 |

- |

345 |

345 |

| 2 |

- |

- |

- |

0.050 |

- |

414 |

414 |

| 3 |

- |

- |

- |

0.050 |

- |

455 |

455 |

| EN10217-1 |

P195TR1 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P195TR2 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P235TR1 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P235TR2 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265TR1 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| P265TR2 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10217-2 |

P195GH |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10217-5 |

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10219-1 |

S235JRH |

0.17 |

- |

1.40 |

0.040 |

0.040 |

360 |

360 |

| S275JOH |

0.20 |

- |

1.50 |

0.035 |

0.035 |

410 |

410 |

| S275J2H |

0.20 |

- |

1.50 |

0.030 |

0.030 |

410 |

410 |

| S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

470 |

470 |

| S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

| S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

Comparison of SSAW Pipes with LSAW and ERW Pipes

| Feature |

SSAW Pipe |

LSAW Pipe |

ERW Pipe |

| Welding Process |

Spiral SAW |

Longitudinal SAW |

Electric Resistance |

| Diameter Range |

20–100 inches |

16–72 inches |

1/8–24 inches |

| Wall Thickness |

5.0–25.4 mm |

6.0–40.0 mm |

1.5–20 mm |

| Applications |

Water, piling, low-pressure systems |

Oil/gas, construction, high-pressure |

Water, gas, low-pressure |

| Weld Quality |

Moderate (Spiral Weld) |

High (Double-Sided SAW) |

Moderate |

| Cost |

Low to Moderate |

Moderate to High |

Low |

SSAW Pipes offer cost-effective, large-diameter solutions compared to LSAW and ERW

pipes, ideal for water, piling, and low-pressure applications. Below is a comparison of key features.

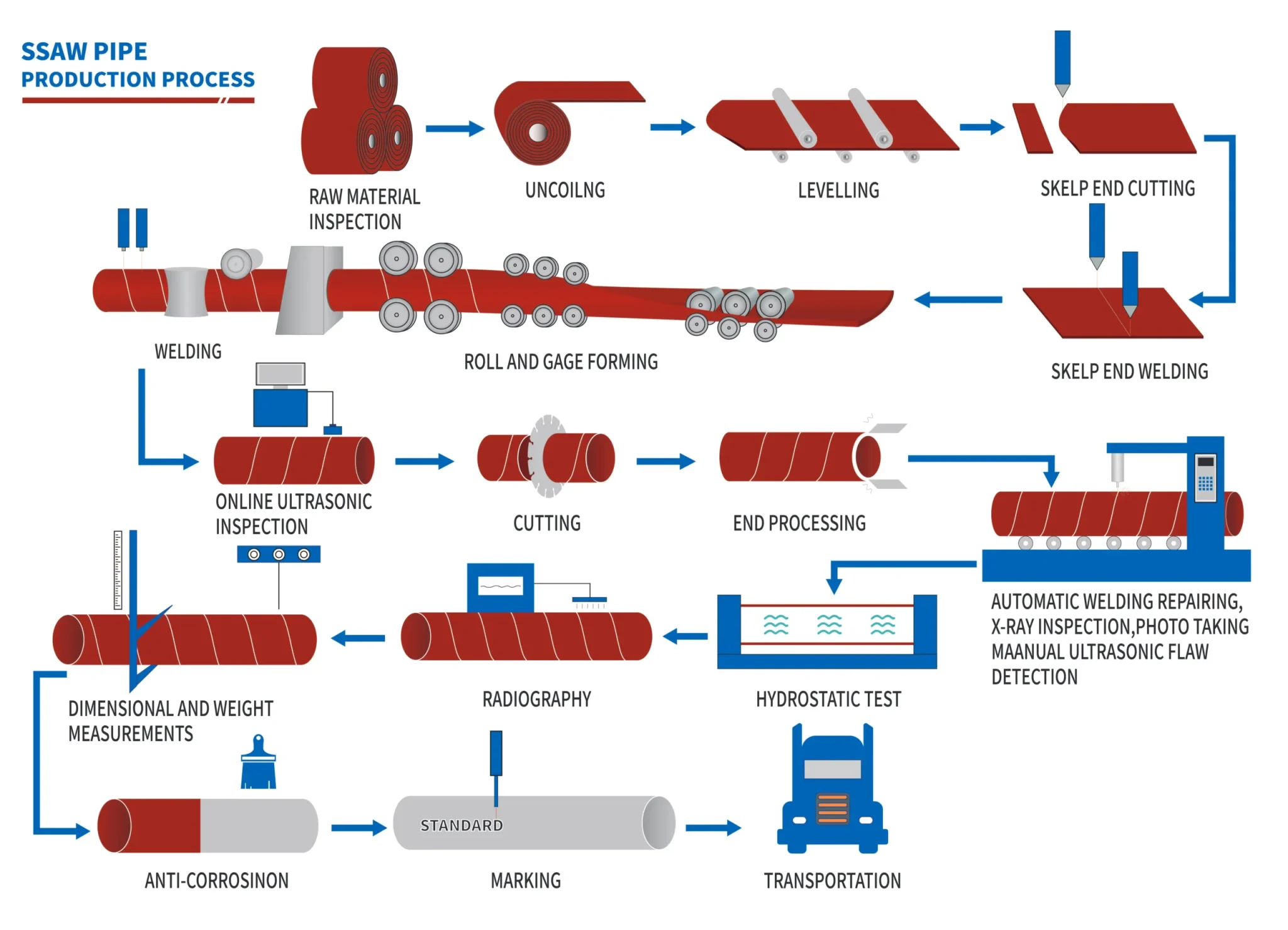

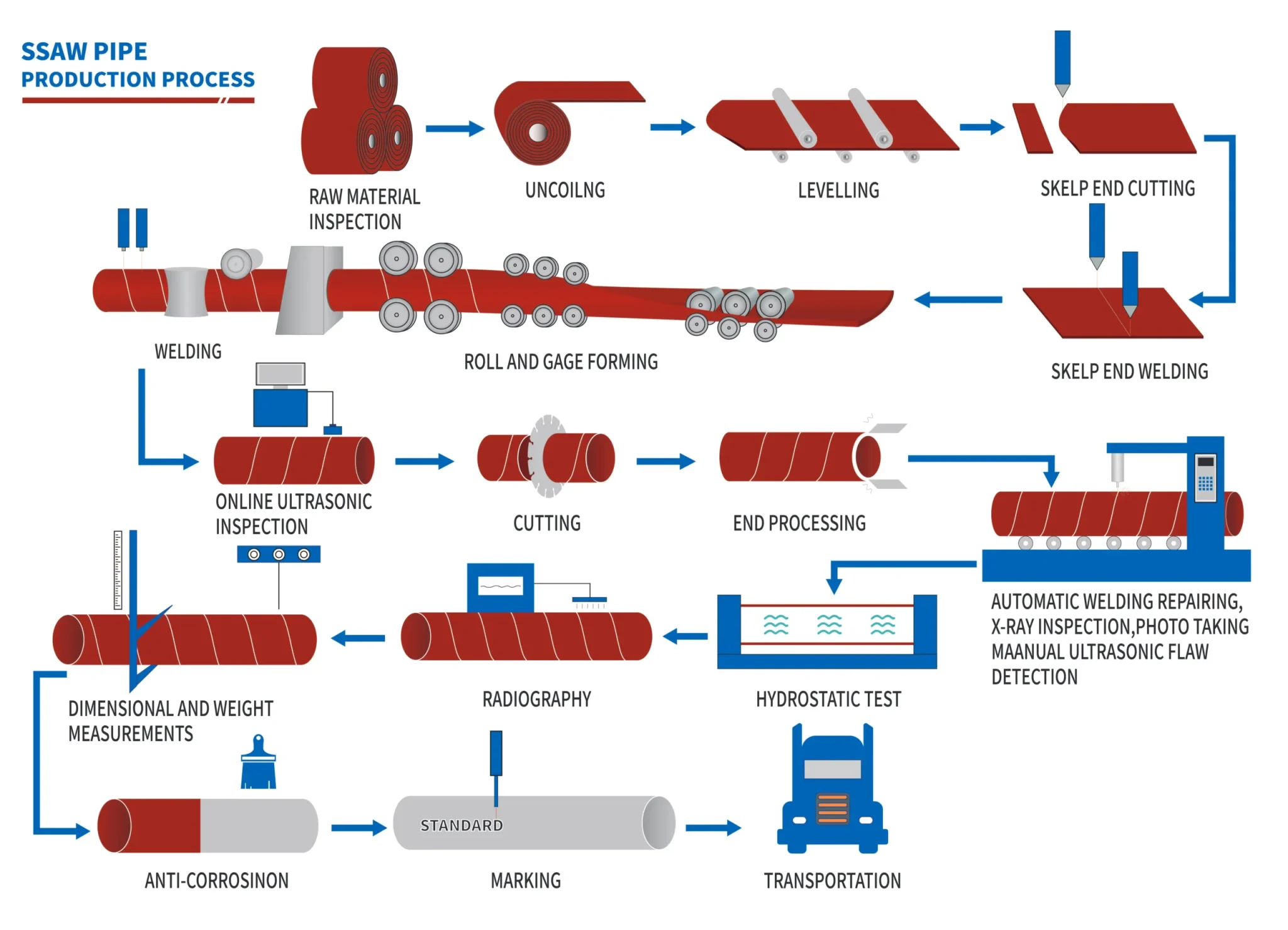

Spiral Submerged-arc Welded steel pipe technological process

Spiral welded pipe production by submerged arc method is based on using tandem welding technique for joining inside and outside coil edges, which have been trimmed and beveled by carbide milling for high quality weld structure.

Thermatool designs and manufactures Spiral Seam Annealing systems for producers of SAW (submerged arc welded) API line pipe.

Offering all the basic features and benefits of Thermatool seam annealing systems designed for operation on longitudinally welded API pipe, Thermatool Spiral Seam Annealing systems, however, require the installation of specially “shaped” inductors.

These are custom designed on CAD systems in order to precisely follow the helix angle for a specific pipe diameter.

The manufacturing process of the spiral steel tube (SSAW):

- The raw materials are strip coil, welding wire and flux. They must undergo strict physical and chemical inspections before being put into use.

- The head and tail of the strip are butted by single wire or double wire submerged arc welding, and automatic submerged arc welding is used for repair welding after rolling into a steel pipe.

- Before forming, the strip is leveled, trimmed, planed, surface cleaned and conveyed and pre-bending.

- The electric contact pressure gauge is used to control the pressure of the cylinder on both sides of the conveyor to ensure the smooth conveying of the strip.

- Adopt external control or internal control roll forming.

- The weld gap control device is used to ensure that the weld gap meets the welding requirements, and the pipe diameter, the amount of misalignment and the weld gap are strictly controlled.

- Both internal welding and external welding use the American Lincoln welding machine for single wire or double wire submerged arc welding, so as to obtain stable welding specifications.

- The welded seams are all inspected by an online continuous ultrasonic automatic flaw tester, which ensures 100% non-destructive testing coverage of the spiral welds. If there is a defect, it will automatically alarm and spray the mark, and the production workers can adjust the process parameters at any time accordingly to eliminate the defect in time.

- Use an air plasma cutting machine to cut the steel pipe into single pieces.

- After cutting into a single steel pipe, each batch of steel pipes must undergo a strict first inspection system to check the mechanical properties, chemical composition, fusion condition of the weld, the surface quality of the steel pipe and non-destructive testing to ensure that the pipe making process is qualified. Only then can it be officially put into production.

- The parts with continuous sonic flaw detection marks on the welds shall be re-examined by manual ultrasonic wave and X-ray. If they are indeed defective, they shall be repaired and subjected to non-destructive inspection again until it is confirmed that the defects have been eliminated.

- The tube where the strip butt welding seam and the T-joint intersecting with the spiral welding seam are located shall all be inspected by X-ray television or filming.

- Each steel pipe is tested by hydrostatic pressure, and the pressure is radially sealed. The test pressure and time are strictly controlled by the water pressure microcomputer detection device of the steel pipe. The test parameters are automatically printed and recorded.

- The pipe end is machined so that the verticality of the end face, the bevel angle and the blunt edge are accurately controlled.

Listing some notes You must know

- Oiled marking: Steel after passing wrer oiled to prevent corrosion,and according to user requirements for making.

- Leveling Milling: The flat steel anvil machine so that the origal curl,and then thouth the edge milling machine for two-sided steel milling,so as to meet the requirements of the plate width,plate edge parallelism and groove shape.

- Shear molding: The steel plate production line along the outer edge of the spiral curl into a tube.

- Butt cut: Double-sided submerged arc welding using advanced technology to pre-welding,internal welding,outside wilding.The welded steel pipe using a plasma-foot cut to specification length.

Why Choose our spiral welded pipe?

Quality Assurance

Our Spiral Welded Pipes undergo meticulous quality checks at every stage of production.

Customization Services

Our Spiral Welded Pipes are customizable to meet your unique project requirements.

Robust Technical Support

Contact us online or send an email to sales@sunnysteel.com to find our professional technical support team.

Competitive Pricing

Experience the perfect balance of quality and affordability. Our Pipes are cost-effective. They do not compromise on the durability and performance you need.

Timely Delivery

We have 20,000 tons of steel pipes in stock, and we have more than 20 years of steel pipe export experience. We take pride in our fast supply chain.

Standards Compliance

Meets API 5L, ASTM A252, and GB/T9711 standards.