UOE Pipe (U-ing, O-ing, Expanding Welded Pipe) is a premium Longitudinal Submerged Arc Welded (LSAW) pipe manufactured through the UOE process, known for its exceptional strength and precision. Ideal for oil and gas pipelines, water transmission, structural construction, petrochemical industries, piling, and abrasive material transport, UOE pipes meet standards like API 5L, ASTM A671, and GB/T3091-2008.

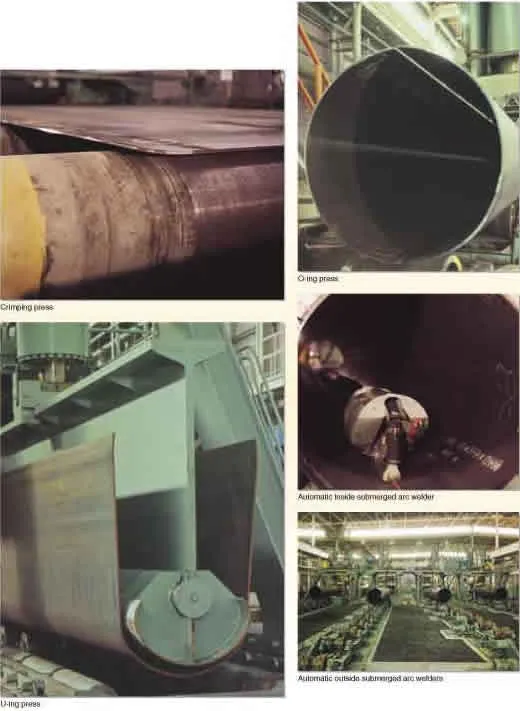

The UOE process involves forming steel plates into a U-shape, then an O-shape, followed by double-sided submerged arc welding (SAW) and mechanical expansion to ensure dimensional accuracy and stress relief. Available in diameters from 20 to 56 inches (508–1422 mm) and wall thicknesses from 6.4 to 40.0 mm, UOE pipes are designed for high-pressure and large-scale applications. Protective coatings like 3LPE or FBE enhance corrosion-resistant UOE pipe performance in harsh environments.

UOE pipes undergo rigorous testing, including ultrasonic, hydrostatic, and X-ray inspections, to ensure superior weld integrity and compliance with industry standards. The process’s high precision makes it ideal for demanding applications like offshore oil pipelines and petrochemical facilities, where reliability is critical.

Compared to JCOE or SSAW pipes, UOE pipes offer higher dimensional accuracy and weld quality, making them a preferred choice for high-pressure applications. Their robust construction ensures reliability in structural and fluid transport systems, particularly in challenging environments.

UOE pipes address challenges such as corrosion, high pressure, and structural demands, providing engineers with dependable large-diameter UOE pipe solutions for critical infrastructure, ensuring safety and longevity.

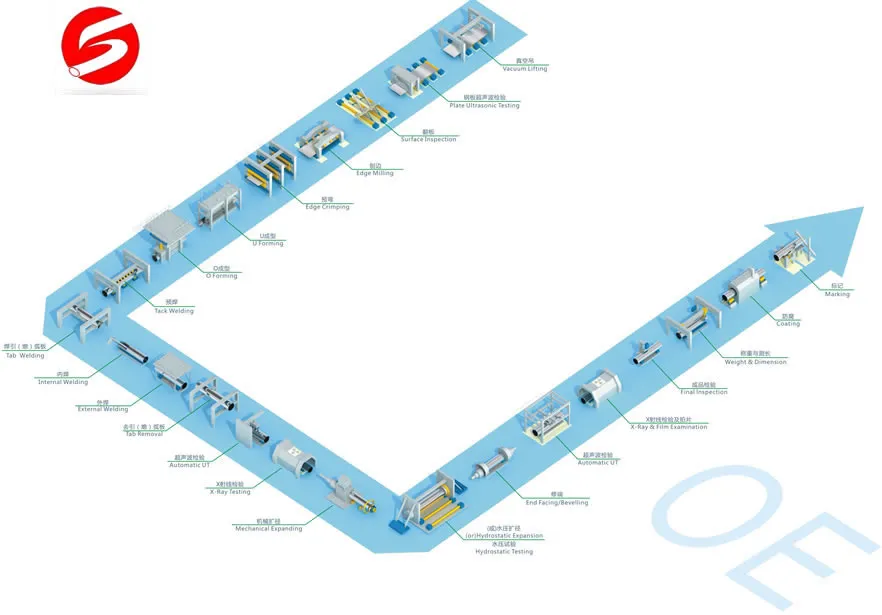

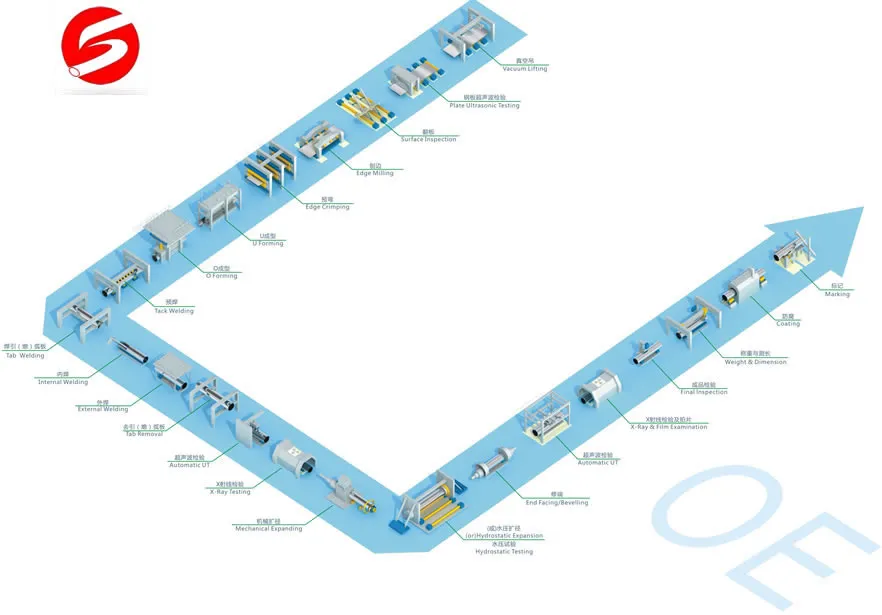

Process of UOE pipe

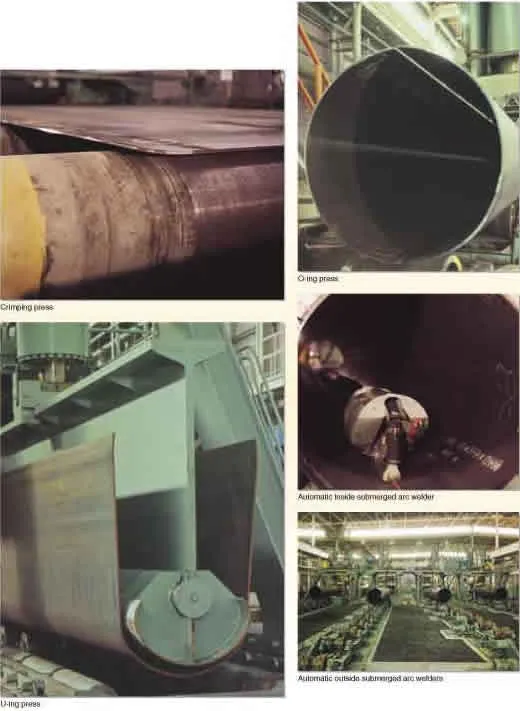

The process of producing UOE pipe involves the following main steps:

UOE manufacturing process

- Trimming: The longitudinal edges of the plate are trimmed by milling to bring the width to the required value, and the ends are beveled to form v-grooves for welding.

- Pre-bending: The edges of the plate are pre-bent to form a U shape using dedicated forming presses.

- U-forming: The U-shaped plate is then pressed using a U-forming press to form a J shape.

- O-forming: The J-shaped plate is then pressed using an O-forming press to form the final round shape.

- Welding: The edges of the plate are welded together longitudinally to form a continuous seam.

- Expanding: The welded pipe is then expanded to its final diameter using an expanding machine.

- Final processing: The UOE pipe is then subjected to various finishing processes, including trimming, end facings, weld testing, and coating, depending on the desired end-use application.

The UOE process is known for its ability to produce large-diameter pipes with high accuracy and consistency, making them suitable for use in the transportation of oil and gas, as well as in various other applications.

The UOE mill features the most advanced technology and process, achieves high production efficiency, stable product quality and is equipped with complete inspection equipments.

UOE mill adopts U & O forming, the formed pipes are welded inside through five internal welding stations with three wires, and welded outside through four external welding stations with three wires.

SSAW pipes combine cost efficiency with durability, making them

ideal for large-scale infrastructure projects requiring large-diameter, high-capacity

pipelines.

UOE Pipe Specifications

Industrial Materials

UOE Pipe Size Range and Specifications

UOE-formed Longitudinal Submerged Arc Welded (LSAW) pipes are manufactured to precise specifications, ensuring high-strength solutions for critical pipeline applications.

UOE pipes are available with an outside diameter of Φ508–1118 mm (20"–44"), wall thickness of 6.0–30.0 mm (1/4"–1"), and lengths of 9–12.3 m (30'–40'). They comply with quality standards such as API, DNV, ISO, DEP, EN, ASTM, DIN, BS, GB, and CSA, and are available in grades from API 5L A-X90 and GB/T9711 L190-L625, meeting diverse industrial requirements.

UOE pipes size range:

- Outside Diameter: Φ508mm- 1118mm (20"- 44")

- Wall Thickness: 6.0mm-30.0mm(1/4"-1")

- Length: 9m-12.3m (30'- 40')

Quality Standards: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、GB、CSA

Grades: API 5L A-X90,GB/T9711 L190-L625

In accordance with different requirements of the customers, the welded pipe can be expanded either by mechanical or hydrostatic expander to improve dimensional accuracy, and eliminate residual stress.

UOE pipes offer precise sizing and robust quality, making them ideal for high-pressure, large-scale infrastructure projects.

Steel Pipe Classification, Standards and Main Products

| Classification |

Standard |

Main Products |

| Steel Pipe for

Fluid Service |

GB/T 14291 |

Welded pipe for mine fluid service |

| GB/T 3091 |

Welded pipe for low pressure fluid service |

| SY/T 5037 |

Spirally submerged arc welded steel pipe for pipelines for low

pressure fluid service |

| ASTM A53 |

Black and hot-dipped galvanized welded and seamless steel pipe

|

| BS EN10217-2 |

Welded steel tubes for pressure purposes - delivery technical

conditions - part2: Electric welded non-alloy and alloy steel tubes with specified

elevated temperature properties |

| BS EN10217-5 |

Welded steel tubes for pressure purposes - delivery technical

conditions - part5: submerged arc welded non-alloy and alloy steel tubes with specified

elevated temperature properties |

| Steel Pipe for

Ordinary Structure |

GB/T 13793 |

Longitudinally electric resistance welded steel pipe |

| SY/T 5040 |

Spirally submerged arc welded steel pipe piles |

| ASTM A252 |

Welded and seamless steel pipe piles |

| BS EN10219-1 |

Cold formed welded structural hollow sections of non-alloy and

fine grain steels - part1: Technical delivery conditions |

| BS EN10219-2 |

Cold formed welded structural hollow sections of non-alloy and

fine grain steels - part2: tolerances, dimensions and sectional properties |

| Line Pipe |

GB/T 9711.1 |

Steel pipe for pipeline transportation system of petroleum and

natural gas industries (Class A steel pipe) |

| GB/T 9711.2 |

Steel pipe for pipeline transportation system of petroleum and

natural gas industries (Class B steel pipe) |

| API 5L PSL1/2 |

Line pipe |

| Casing |

API 5CT/ ISO 11960 PSL1 |

Steel pipe for use as casing or tubing for wells of petroleum and

natural gas industries |

The chemical composition ensures weldability, strength, and corrosion resistance for

SAW pipe in demanding applications.

SSAW is not stocked rather can easily be sourced for projects across the below range

| NOMINAL SIZE DN |

IMPERIAL SIZE |

OUTSIDE DIAMETER MM (Ø) |

WALL THICKNESS MM (t) |

TYPE |

LENGTH |

MASS KG/METRE |

| 350 |

14" |

355.6 |

6.4 |

SSAW |

12 |

55.12 |

| 350 |

14" |

355.6 |

9.5 |

SSAW |

9 |

81.09 |

| 350 |

14" |

355.6 |

9.5 |

SSAW |

12 |

81.09 |

| 350 |

14" |

355.6 |

12.7 |

SSAW |

12 |

107.4 |

| 350 |

14" |

355.6 |

15.9 |

SSAW |

12 |

133.2 |

| 350 |

14" |

406.4 |

25.4 |

SSAW |

12 |

206.46 |

| 400 |

16" |

406.4 |

6.4 |

SSAW |

12 |

63.13 |

| 400 |

16" |

406.4 |

9.5 |

SSAW |

12 |

92.99 |

| 400 |

16" |

406.4 |

12.7 |

SSAW |

12 |

123.31 |

| 400 |

16" |

406.4 |

15.9 |

SSAW |

12 |

153.12 |

| 450 |

18" |

457 |

6.4 |

SSAW |

12 |

71.12 |

| 450 |

18" |

457 |

9.5 |

SSAW |

12 |

104.84 |

| 450 |

18" |

457 |

12.7 |

SSAW |

12 |

139.16 |

| 450 |

18" |

457 |

15.9 |

SSAW |

12 |

172.96 |

| 500 |

20" |

508 |

6.4 |

SSAW |

12 |

79.17 |

| 500 |

20" |

508 |

9.5 |

SSAW |

12 |

116.79 |

| 500 |

20" |

508 |

12.7 |

SSAW |

12 |

155.13 |

| 500 |

20" |

508 |

15.9 |

SSAW |

12 |

192.96 |

| 500 |

20" |

508 |

16 |

SSAW |

13 |

194.14 |

| 550 |

22" |

559 |

12.5 |

SSAW |

12 |

168.47 |

| 550 |

22" |

559 |

16 |

SSAW |

12 |

214.26 |

| 600 |

24" |

610 |

6.4 |

SSAW |

12 |

95.27 |

| 600 |

24" |

610 |

9.5 |

SSAW |

12 |

140.69 |

| 600 |

24" |

610 |

12.7 |

SSAW |

12 |

187.07 |

| 600 |

24" |

610 |

15.9 |

SSAW |

12 |

232.96 |

| 600 |

24" |

610 |

17.48 |

SSAW |

12 |

255.43 |

| 600 |

24" |

610 |

20 |

SSAW |

12 |

291.01 |

| 600 |

24" |

610 |

25.4 |

SSAW |

12 |

366.19 |

| 600 |

24" |

610 |

31 |

SSAW |

12 |

442.65 |

| 650 |

26" |

660 |

10 |

SSAW |

12 |

160.3 |

| 650 |

26" |

660 |

12.7 |

SSAW |

12 |

202.74 |

| 650 |

26" |

660 |

20 |

SSAW |

12 |

315.67 |

| 700 |

28" |

711 |

9.5 |

SSAW |

12 |

164.35 |

| 700 |

28" |

711 |

12.7 |

SSAW |

12 |

218.71 |

| 700 |

28" |

711 |

15.9 |

SSAW |

12 |

272.56 |

| 700 |

28" |

711 |

20 |

SSAW |

13 |

340.82 |

| 750 |

30" |

762 |

9.5 |

SSAW |

12 |

176.3 |

| 750 |

30" |

762 |

12.7 |

SSAW |

12 |

234.68 |

| 750 |

30" |

762 |

15.9 |

SSAW |

12 |

292.56 |

| 750 |

30" |

762 |

20 |

SSAW |

12 |

365.9 |

| 800 |

32" |

813 |

9.5 |

SSAW |

12 |

188.25 |

| 800 |

32" |

813 |

12.7 |

SSAW |

12 |

250.66 |

| 800 |

32" |

813 |

16 |

SSAW |

12 |

314.48 |

| 800 |

32" |

813 |

20 |

SSAW |

12 |

391.13 |

| - |

- |

820 |

16 |

SSAW |

11.9 |

317.25 |

| 850 |

34" |

864 |

7.9 |

SSAW |

8 |

166.79 |

| 900 |

36" |

914 |

9.5 |

SSAW |

12 |

211.91 |

| 900 |

36" |

914 |

12.7 |

SSAW |

12 |

282.29 |

| 900 |

36" |

914 |

15.9 |

SSAW |

12 |

352.16 |

| - |

- |

900 |

20 |

SSAW |

12 |

434.04 |

| 900 |

36" |

914 |

20 |

SSAW |

12 |

440.95 |

| 950 |

38" |

965 |

9.5 |

SSAW |

6.2 |

223.86 |

| 1000 |

40" |

1016 |

10 |

SSAW |

12 |

248.09 |

| 1000 |

40" |

1016 |

16 |

SSAW |

12 |

394.58 |

| - |

- |

1032 |

20 |

SSAW |

7.2 |

499.15 |

| 1050 |

42" |

1067 |

9.5 |

SSAW |

12 |

247.76 |

| 1050 |

42" |

1067 |

12.7 |

SSAW |

12 |

330.21 |

| 1050 |

42" |

1067 |

15.9 |

SSAW |

12 |

412.16 |

| 1200 |

48" |

1219 |

9.5 |

SSAW |

12 |

283.37 |

| 1200 |

48" |

1219 |

12.7 |

SSAW |

12 |

377.81 |

| 1200 |

48" |

1219 |

15.9 |

SSAW |

12 |

471.76 |

| 1200 |

48" |

1219 |

20 |

SSAW |

12 |

591.38 |

Note:

Pipes can be sourced conforming to AS/NZS3678 Grade 350 L0 & manufactured to AS/NZS1163 tolerances & to grade C350 L0.

Pipes/piles can be sourced at longer lengths or with piling shoes spliced/welded to AS1554.1.

Chemical Composition and Mechanical Properties of Various Pipe Standards

| Standard |

Grade |

Chemical Composition (max %) |

Mechanical Properties (min) |

| C |

Si |

Mn |

P |

S |

Tensile Strength (MPa) |

Yield Strength (MPa) |

| API 5CT |

H40 |

- |

- |

- |

- |

0.030 |

417 |

417 |

| J55 |

- |

- |

- |

- |

0.030 |

517 |

517 |

| K55 |

- |

- |

- |

- |

0.300 |

655 |

655 |

| API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

| B |

0.26 |

- |

1.20 |

0.030 |

0.030 |

415 |

415 |

| X42 |

0.26 |

- |

1.30 |

0.030 |

0.030 |

415 |

415 |

| X46 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

435 |

435 |

| X52 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

460 |

460 |

| X56 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

490 |

490 |

| X60 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

520 |

520 |

| X65 |

0.26 |

- |

1.45 |

0.030 |

0.030 |

535 |

535 |

| X70 |

0.26 |

- |

1.65 |

0.030 |

0.030 |

570 |

570 |

| API 5L PSL2 |

B |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

415 |

415 |

| X42 |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

415 |

415 |

| X46 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

435 |

435 |

| X52 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

460 |

460 |

| X56 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

490 |

490 |

| X60 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

520 |

520 |

| X65 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

535 |

535 |

| X70 |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

570 |

570 |

| X80 |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

625 |

625 |

| ASTM A53 |

A |

0.25 |

0.10 |

0.95 |

0.050 |

0.045 |

330 |

330 |

| B |

0.30 |

0.10 |

1.20 |

0.050 |

0.045 |

415 |

415 |

| ASTM A252 |

1 |

- |

- |

- |

0.050 |

- |

345 |

345 |

| 2 |

- |

- |

- |

0.050 |

- |

414 |

414 |

| 3 |

- |

- |

- |

0.050 |

- |

455 |

455 |

| EN10217-1 |

P195TR1 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P195TR2 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P235TR1 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P235TR2 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265TR1 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| P265TR2 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10217-2 |

P195GH |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

| P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10217-5 |

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

| P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

| EN10219-1 |

S235JRH |

0.17 |

- |

1.40 |

0.040 |

0.040 |

360 |

360 |

| S275JOH |

0.20 |

- |

1.50 |

0.035 |

0.035 |

410 |

410 |

| S275J2H |

0.20 |

- |

1.50 |

0.030 |

0.030 |

410 |

410 |

| S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

470 |

470 |

| S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

| S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

Comparison of SSAW Pipes with LSAW and ERW Pipes

| Feature |

SSAW Pipe |

LSAW Pipe |

ERW Pipe |

| Welding Process |

Spiral SAW |

Longitudinal SAW |

Electric Resistance |

| Diameter Range |

20–100 inches |

16–72 inches |

1/8–24 inches |

| Wall Thickness |

5.0–25.4 mm |

6.0–40.0 mm |

1.5–20 mm |

| Applications |

Water, piling, low-pressure systems |

Oil/gas, construction, high-pressure |

Water, gas, low-pressure |

| Weld Quality |

Moderate (Spiral Weld) |

High (Double-Sided SAW) |

Moderate |

| Cost |

Low to Moderate |

Moderate to High |

Low |

SSAW Pipes offer cost-effective, large-diameter solutions compared to LSAW and ERW

pipes, ideal for water, piling, and low-pressure applications. Below is a comparison of key features.