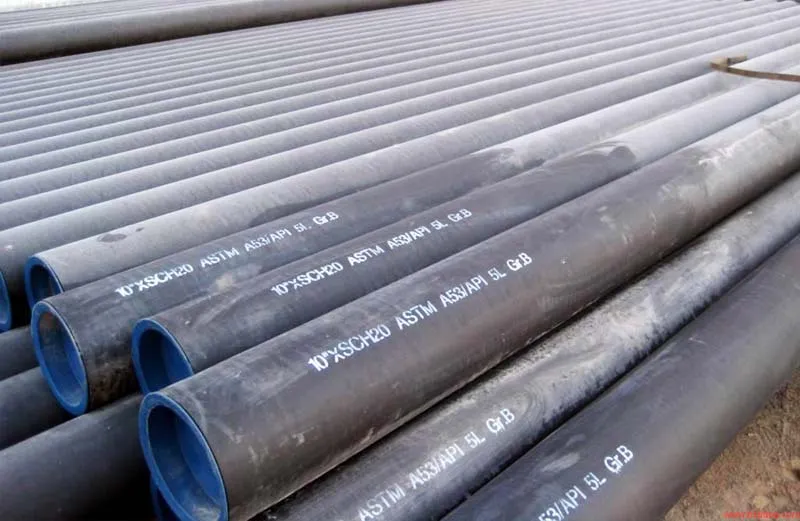

High-strength Carbon Steel Pipes For Fluid And Structural Applications

Astm a53 grade b pipes offer high-strength, corrosion-resistant solutions for water, gas, oil, and structural applications.

High-strength Carbon Steel Pipes For Fluid And Structural Applications

Astm a53 grade b pipes offer high-strength, corrosion-resistant solutions for water, gas, oil, and structural applications.

ASTM A53 Grade B Pipes, compliant with ASME SA53, are carbon steel pipes designed for mechanical and pressure applications, including water, gas, oil, and air conveyance. Available in seamless, electric-resistance-welded (ERW), and furnace-welded types, these pipes offer a minimum tensile strength of 415 MPa and yield strength of 240 MPa, making them ideal for demanding applications in water supply, oil and gas pipelines, and fire sprinkler systems.

Manufactured through seamless, ERW, or furnace-welded processes, ASTM A53 Grade B Pipes come in sizes from NPS 1/8 to 26 [DN 6–650] with wall thicknesses ranging from SCH 10 to SCH 160. The pipes can be black or hot-dipped galvanized, with galvanization providing enhanced corrosion-resistant steel pipes for prolonged durability in harsh environments. The ERW pipes undergo heat treatment post-welding to ensure weld integrity, eliminating untempered martensite.

Rigorous testing, including tensile, flattening, hydrostatic, and nondestructive electric tests, ensures compliance with ASTM A53 standards. These pipes are suitable for welding, coiling, bending, and flanging, with specific qualifications for continuous-welded pipes. Available in standard lengths (16–22 ft for single random, 22–35 ft for double random) or customized, they meet diverse project requirements.

Compared to ASTM A106 Grade B, ASTM A53 Grade B Pipes are optimized for low to medium-pressure applications, offering cost-effective solutions with excellent strength and versatility. Their galvanized variants resist corrosion, making them suitable for outdoor and high-moisture environments like water distribution and HVAC systems.

ASTM A53 Grade B Pipes address challenges like pipeline corrosion, wear, and pressure demands, providing reliable, durable solutions for fluid conveyance and structural applications in industrial and construction settings.

Heat treatment:

After welding,all tubes shall be heat treated at a temperature of 1650°F(900℃) or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace,Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F(650℃)or higher.

Surface Condition:

Finished tubes shall be free of scale,A slight amount of oxidation will not be considered as scale.

Mechanical Tests Required:

Flattenting Test/Flaring test/Flange test/Crush test/Tension test/Reverse Flattening test/Hydrostatic or Nondestructive Electric Test

ASTM A53 Grade B Pipe Overview

ASTM A53 Grade B pipe is a carbon steel pipe, either seamless or welded, designed for mechanical and pressure applications, including water, gas, and steam transport.

ASTM A53 Grade B pipe, part of the ASTM A53 standard, is manufactured using either seamless or electric resistance welded (ERW) processes. It is a carbon steel pipe with higher strength than Grade A, suitable for mechanical, pressure, and structural applications. Commonly used for conveying water, gas, steam, and air, it is widely applied in industries like construction, oil and gas, and plumbing, meeting standards such as ASTM A53 and ASME B36.10.

Grade B pipes typically have a minimum tensile strength of 60,000 psi and a minimum yield strength of 35,000 psi. Available with coatings like galvanized, black, or anti-corrosion (e.g., 3LPE), they undergo rigorous testing, including hydrostatic, non-destructive, and flattening tests, to ensure weld integrity and durability for applications like pipelines, structural supports, and fire protection systems.

ASTM A53 Grade B pipes offer reliable, high-strength solutions for fluid transport and structural applications, ensuring performance and longevity.

Minimum tensile strength of 415 MPa for demanding applications.

Galvanized coatings enhance durability in harsh environments.

Available in seamless, ERW, and furnace-welded types.

NPS 1/8–26 with customizable lengths for diverse projects.

Affordable solution for low to medium-pressure systems.

Meets ASTM A53 and ASME SA53 standards.

Explore ASTM A53 Grade B Pipes with targeted long-tail keywords for specifications, applications, and materials.

Note: ASTM A53 Grade B Pipes meet international standards, ensuring high performance and reliability. Contact suppliers for detailed specifications.

| Element | Composition (% max) |

|---|---|

| Carbon (C) | 0.30 |

| Manganese (Mn) | 1.20 |

| Phosphorus (P) | 0.05 |

| Sulfur (S) | 0.045 |

| Copper (Cu) | 0.40 |

| Nickel (Ni) | 0.40 |

| Chromium (Cr) | 0.40 |

| Molybdenum (Mo) | 0.15 |

| Vanadium (V) | 0.08 |

The chemical composition ensures weldability and durability for ASTM A53 Grade B Pipes in fluid conveyance and structural applications.

| Property | Value |

|---|---|

| Tensile Strength (min, ksi [MPa]) | 60 [415] |

| Yield Strength (min, ksi [MPa]) | 35 [240] |

| Elongation (min, %) | 30 |

These properties ensure ASTM A53 Grade B Pipes deliver robust performance in pressure and structural applications.

| Feature | ASTM A53 Grade B | ASTM A106 Grade B | ASTM A135 Grade B |

|---|---|---|---|

| Manufacturing Process | Seamless/ERW/Furnace-Welded | Seamless | ERW |

| Diameter Range | NPS 1/8–26 | NPS 1/8–48 | NPS 2–30 |

| Applications | Water, gas, oil, structural | High-temperature services | Fire sprinklers, fluid conveyance |

| Tensile Strength (min, MPa) | 415 | 415 | 415 |

| Corrosion Resistance | Galvanized option | Not typically galvanized | Galvanized option |

| Cost | Moderate | High | Moderate |

ASTM A53 Grade B Pipes are engineered for high-strength performance in water supply systems, gas and oil pipelines, fire sprinkler systems, HVAC systems, low-pressure fluid conveyance, and structural applications.

Durable pipes for municipal and industrial water distribution.

High-strength pipes for safe gas and oil transportation.

Reliable pipes for fire protection in buildings.

Efficient piping for heating and cooling applications.

Cost-effective pipes for low-pressure liquid transport.

High-strength pipes for structural support in construction.

Why Choose ASTM A53 Grade B Pipes? Their high-strength, corrosion-resistant design ensures reliable performance in critical fluid conveyance and structural applications.

Hot-dip galvanized pipes provide superior corrosio...

Astm a135 grade b erw pipe offers high-strength so...

Astm a178 tubes offer reliable, cost-effective erw...

Astm a214 erw boiler tubes offer high-strength, co...