High-strength Structural Steel Tubes For Construction And Industry

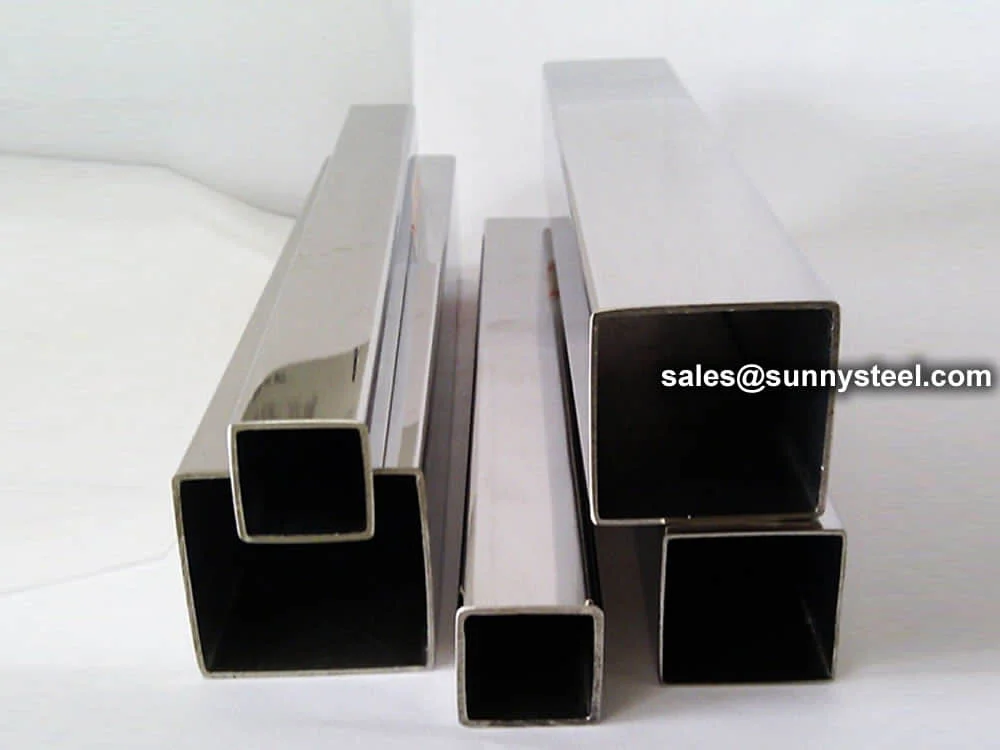

Square hollow sections offer high-strength, corrosion-resistant solutions for structural frameworks, construction, and industrial applications.

High-strength Structural Steel Tubes For Construction And Industry

Square hollow sections offer high-strength, corrosion-resistant solutions for structural frameworks, construction, and industrial applications.

Square Hollow Section Overview

Square Hollow Sections (SHS) are versatile steel profiles with symmetrical equal sides, ideal for structural, construction, and mechanical applications.

SHS are manufactured using Electric Resistance Welding (ERW) or similar processes, forming steel strips into square shapes with equal sides for a symmetrical appearance. These sections offer high strength-to-weight ratios and require minimal edge preparation for welding and joining, making them suitable for building frameworks, bridges, machinery, and structural supports.

Rigorous testing ensures compliance with industry standards, and surface treatments like galvanizing or protective coatings (e.g., 3LPE, FBE) enhance corrosion resistance, ensuring durability in demanding construction and mechanical environments.

Square Hollow Sections provide robust, aesthetically balanced solutions for diverse structural applications, ensuring reliability and ease of use.

Square Hollow Section (SHS) tubes are cold-formed, welded steel tubes with a square cross-section, designed for structural and mechanical applications. Compliant with standards like EN 10219, ASTM A500, and JIS G3466, these tubes offer high strength-to-weight ratios, with tensile strengths ranging from 355 to 630 MPa depending on the grade, making them ideal for structural frameworks, construction columns, and fencing.

Manufactured through electric resistance welding (ERW) or seamless processes, Square Hollow Sections are available in sizes from 20x20 mm to 400x400 mm, with wall thicknesses from 1.5 to 16 mm. Surface treatments such as galvanizing, powder coating, or anti-rust oil enhance corrosion-resistant SHS for outdoor and harsh environments. These sections are produced in standard lengths of 6–12 meters, with customization available for specific project needs.

Rigorous testing, including tensile, bending, and flattening tests, ensures compliance with international standards. The uniform square geometry provides excellent torsional resistance and aesthetic appeal, making Square Hollow Sections suitable for visible structural elements in buildings, bridges, and furniture manufacturing. Their versatility supports welding, bolting, and forming, ensuring compatibility with complex designs.

Compared to rectangular hollow sections (RHS) or I-beams, Square Hollow Sections offer superior load-bearing capacity in all directions due to their symmetrical shape, making them a cost-effective choice for structural applications. Their lightweight design reduces material costs while maintaining durability, ideal for automotive structures and agricultural equipment.

Square Hollow Sections address challenges like structural stability, corrosion, and aesthetic requirements, providing reliable, high-performance solutions for construction and industrial applications.

| Data | Elements(%) | ||||

|---|---|---|---|---|---|

| Material Grade | C | Mn | S | P | Si |

| Q195 | 0.06-0.12 | 0.25-0.50 | <0.05 | <0.045 | <0.30 |

| Q215 | 0.09-0.15 | 0.25-0.55 | <0.05 | <0.045 | <0.30 |

| Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.30 |

| Q345 | <0.20 | 1.0-1.6 | <0.04 | <0.04 | <0.55 |

The chemical composition ensures weldability and durability for Square Hollow Section in fluid conveyance and structural applications.

| Material Grade | Yield Point (Mpa) | Tensile Strength (Mpa) | Elongation (%) |

|---|---|---|---|

| Q195 | >195 | 315-430 | 32-33 |

| Q215 | >215 | 335-450 | 26-31 |

| Q235 | >235 | 375-500 | 24-26 |

| Q345 | >345 | 470-630 | 21-22 |

These properties ensure Square Hollow Section deliver robust performance in pressure and structural applications.

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Square Hollow Section ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Square Hollow Section suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

Square Hollow Section are engineered for high-strength and corrosion-resistant performance in automotive exhaust systems, construction frameworks, oil and gas pipelines, aerospace components, hydraulic systems, and chemical processing, meeting the demands of diverse industries including power generation and agricultural equipment.

efficient overseas shipping options

We specialize in international shipping for Square Hollow Section, ensuring safe and timely delivery worldwide.

Our clients come to us from across the globe for our unique shaped tubing and specialist tube fabrication. We can Square Hollow Section to North America and Europe in as little as soon as posible.

Our expert shipping team will meet your transit times and budget; get in touch to discuss transportation options.

Need help finding

Speak with one of our tube specialists to find out how best to integrate shaped tubing into your project. We can give you information on the best profile, metal, finish and dimensions for your application.

Our team is here to assist you in selecting the perfect size and shape for your specific needs.

Elliptic pipes offer corrosion resistance and aest...

Oval pipes offer corrosion resistance and aestheti...

Flat oval pipes offer corrosion resistance and aes...

Stainless hollow sections offer superior corrosion...

Stainless steel oval pipes offer corrosion resista...

Rectangular hollow sections provide high-strength,...