High-strength Structural Steel Tubes For Versatile Applications

Rectangular hollow sections provide high-strength, corrosion-resistant solutions for structural frameworks, construction, and industrial applications.

High-strength Structural Steel Tubes For Versatile Applications

Rectangular hollow sections provide high-strength, corrosion-resistant solutions for structural frameworks, construction, and industrial applications.

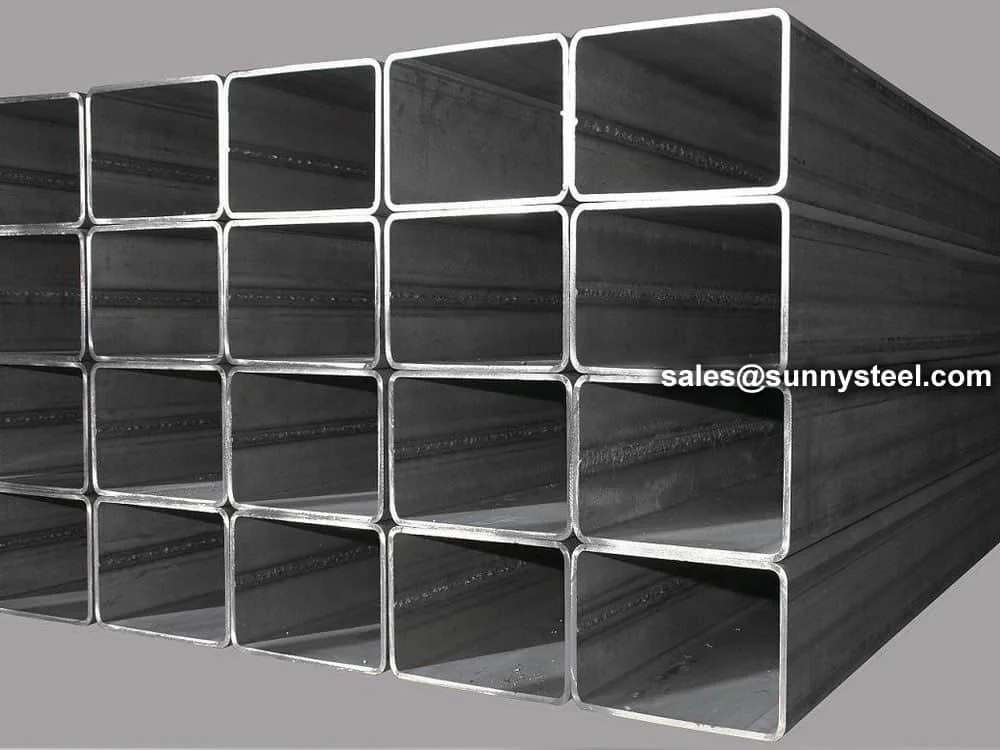

Rectangular Hollow Section stocking

Rectangular Hollow Sections (RHS) are versatile steel profiles used in structural, construction, and mechanical applications, designed for ease of welding and joining.

RHS are manufactured using Electric Resistance Welding (ERW) or similar processes, forming steel strips into rectangular shapes with minimal edge preparation required for welding and joining. These sections offer high strength-to-weight ratios and are ideal for applications in building frameworks, bridges, machinery, and structural supports, providing durability and stability.

Rigorous testing ensures compliance with industry standards, and options for surface treatments like galvanizing or coating enhance corrosion resistance, making RHS suitable for demanding construction and mechanical environments.

Rectangular Hollow Sections provide robust, cost-effective solutions for diverse structural applications, ensuring reliability and ease of use.

Rectangular Hollow Section (RHS) tubes are cold-formed, welded steel tubes with a rectangular cross-section, designed for structural and mechanical applications. Compliant with standards such as EN 10219, ASTM A500, and JIS G3466, these tubes offer high strength-to-weight ratios, with tensile strengths ranging from 355 to 630 MPa depending on the grade, making them ideal for structural frameworks, construction columns, and fencing.

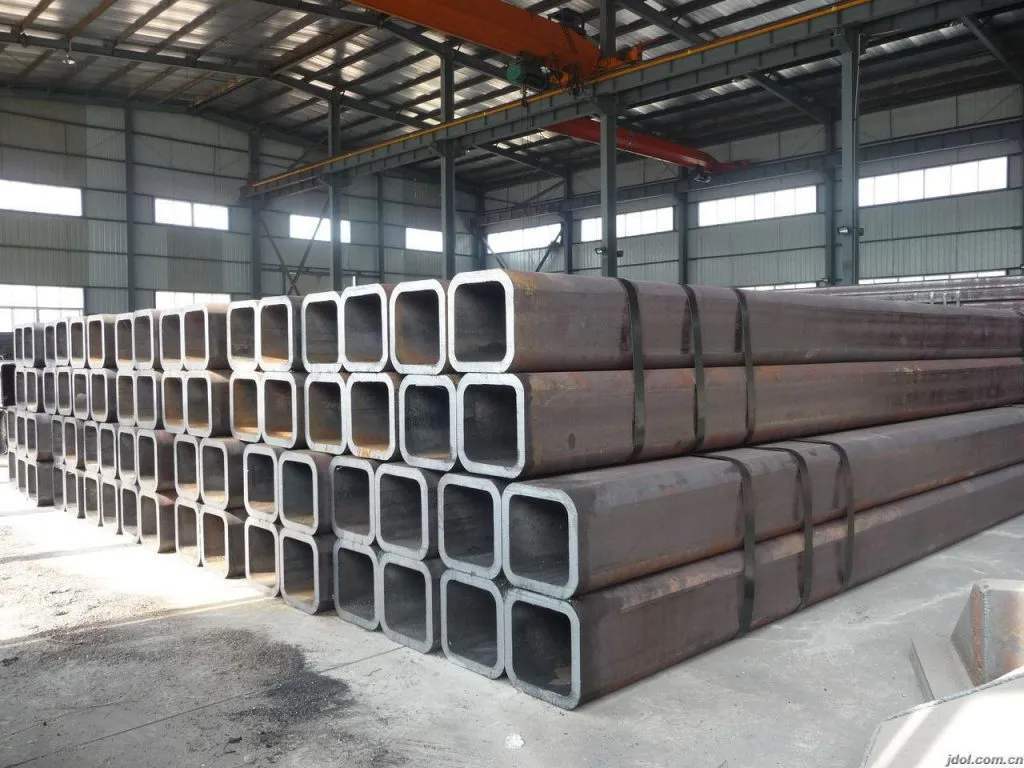

Manufactured through electric resistance welding (ERW) or seamless processes, Rectangular Hollow Sections are available in sizes from 40x20 mm to 500x300 mm, with wall thicknesses from 1.5 to 16 mm. Surface treatments like galvanizing, powder coating, or anti-rust oil enhance corrosion-resistant RHS for outdoor and harsh environments. These sections are produced in standard lengths of 6–12 meters, with customization available for specific project requirements.

Rigorous testing, including tensile, bending, and flattening tests, ensures compliance with international standards. The rectangular geometry provides excellent load-bearing capacity in specific directions, making Rectangular Hollow Sections suitable for visible structural elements in buildings, bridges, and furniture manufacturing. Their versatility supports welding, bolting, and forming, ensuring compatibility with complex designs.

Compared to square hollow sections (SHS) or I-beams, Rectangular Hollow Sections offer directional strength and aesthetic appeal, making them a cost-effective choice for structural applications. Their lightweight design reduces material costs while maintaining durability, ideal for automotive structures and agricultural equipment.

Rectangular Hollow Sections address challenges like structural stability, corrosion, and aesthetic requirements, providing reliable, high-performance solutions for construction and industrial applications.

It is commonly used in construction and structural applications due to its strength and versatility.

Rectangular and square HSS have about two-thirds the surface area of an open section of comparable capacity, resulting in cost savings. There is less surface to prepare, fewer painting materials are required, cementitious fireproofing can be reduced, and minimal labour is needed.

Rectangular Hollow Section tubes are commonly used as structural sections. They provide greater strength and solderability. Typical sizes range from 50 mm x 25 mm up to 450 mm x 250 mm, with wall thicknesses between 2 mm and 20 mm in larger sections.

Their uniformity makes them predictable to use and visually appealing, with a high weight-to-strength ratio.

We manufacture and export Rectangular Hollow Sections, Rectangular Hollow Steel Sections, and Rectangular Hollow Section Tubes as per customer requirements, with anti-rust oil coating inside and outside to ensure safe delivery.

Rectangular Tubes are commonly available in Aluminium, Stainless Steel, Black Steel, and Bright Steel. They can be purchased at Metal Supermarkets locations and cut to exact specifications.

RHS stands for Rectangular Hollow Section. Although often used interchangeably with square hollow section, the correct term for square tube is SHS (Square Hollow Section).

Square tubes and rectangular tubes are common hollow structural sections used in construction, manufacturing, and engineering. The main difference is in their cross-sectional shape:

Rectangular tubes are usually produced by cold rolling or hot rolling. Hot-rolled tubes are made by passing hot-rolled strips through the process. Cold-drawn or cold-rolled precision tubes are used in mechanical structures and hydraulic equipment, offering high dimensional accuracy and smooth surfaces.

Many defects in square tubes occur during perforation, making this step critical. High-alloy materials have low perforation performance, so selecting deformation parameters carefully is important to ensure quality.

RHS (Rectangular Hollow Section) tubing is widely used in construction and fabrication, popular for furniture, frames, and load-bearing applications.

Steel Grades: Q195, Q215, Q235, Q345, S235JR, S275JR, SS400

| Feature | Rectangular Hollow Section | Square Hollow Section | I-Beam |

|---|---|---|---|

| Shape | Rectangular | Square | I-Shaped |

| Size Range | 40x20–500x300 mm | 20x20–400x400 mm | Varies (e.g., 100–600 mm height) |

| Applications | Structural, fencing, furniture | Structural, fencing, furniture | Beams, heavy structures |

| Torsional Resistance | Moderate | High | Low |

| Cost | Cost-Effective | Cost-Effective | Higher |

Explore Rectangular Hollow Sections with targeted long-tail keywords for specifications, applications, and materials.

Note: Rectangular Hollow Sections meet international standards, ensuring high performance and reliability. Contact suppliers for detailed specifications.

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) |

|---|---|---|---|---|---|

| S235 | 0.17 | 1.40 | 0.35 | 0.040 | 0.040 |

| S355 | 0.20 | 1.60 | 0.55 | 0.035 | 0.035 |

The chemical composition ensures weldability and durability for Rectangular Hollow Section in fluid conveyance and structural applications.

| Grade | Tensile Strength (MPa) | Yield Strength (min, MPa) | Elongation (min, %) |

|---|---|---|---|

| S235 | 360–510 | 235 | 26 |

| S355 | 470–630 | 355 | 22 |

These properties ensure Rectangular Hollow Section deliver robust performance in pressure and structural applications.

| Parameter | Tolerance Range |

|---|---|

| Length | ± 50 MM |

| Wall Thickness | ± 12.5% |

| Weight | ± 8% |

| Feature | Special Welded Tubes | Seamless Tubes | ASTM A53 Grade B |

|---|---|---|---|

| Manufacturing Process | ERW, High-Frequency Welded | Hot/Cold-Drawn Seamless | Seamless/ERW/Furnace-Welded |

| Diameter Range | Ø6–2800 mm | Ø4–1219 mm | NPS 1/8–26 |

| Wall Thickness | 0.4–3.0 mm | 0.5–100 mm | Up to 12.7 mm |

| Applications | Automotive, oil/gas, hydraulic | High-pressure, critical systems | Water, gas, structural |

| Cost | Cost-Effective | Higher | Moderate |

Elliptic pipes offer corrosion resistance and aest...

Oval pipes offer corrosion resistance and aestheti...

Flat oval pipes offer corrosion resistance and aes...

Stainless hollow sections offer superior corrosion...

Stainless steel oval pipes offer corrosion resista...

Square hollow sections offer high-strength, corros...