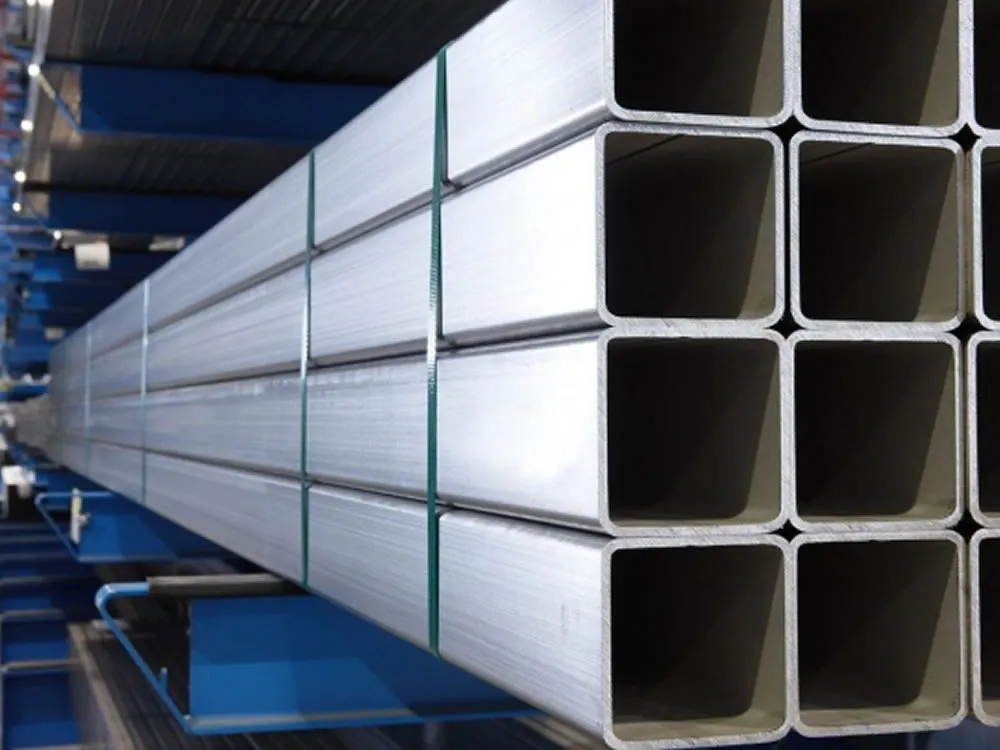

304 Stainless Hollow Section

SHS

Stainless Hollow Sections

Stainless Hollow Sections, including square and rectangular tubes, are durable stainless steel components designed for structural and industrial applications.

Type:Stainless Steel Square Tube, Stainless Steel rectangular Tube, Square Hollow Section, Rectangular Hollow Section

Standard:ASTM A554,ASTM A249,ASTM A312,DIN11850,JIS G3459,JIS G3448,GB/T12770,GB/T12771

Steel Grades: 304/304L,316/316L,301,202,201,409,410,430

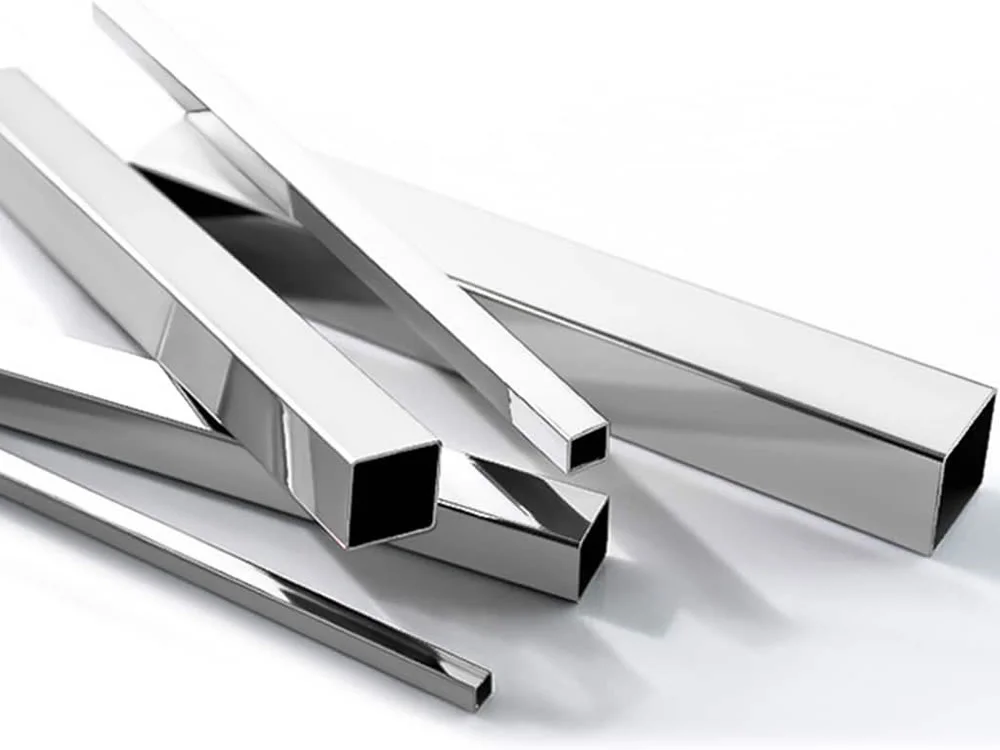

Surface: Pickled, Bright, Matt, Polished, Mirror.

Stainless Hollow Sections provide versatile, corrosion-resistant solutions for structural and decorative applications, meeting stringent industry standards.

Stainless Hollow Sections are precision-welded or seamless stainless steel tubes with square or rectangular cross-sections, designed for structural and aesthetic applications. Compliant with standards like ASTM A554, EN 10296, and ASTM A312, these sections are typically made from austenitic grades like 304 and 316, offering tensile strengths of 515–690 MPa and exceptional corrosion resistance for architectural structures, marine environments, and chemical processing.

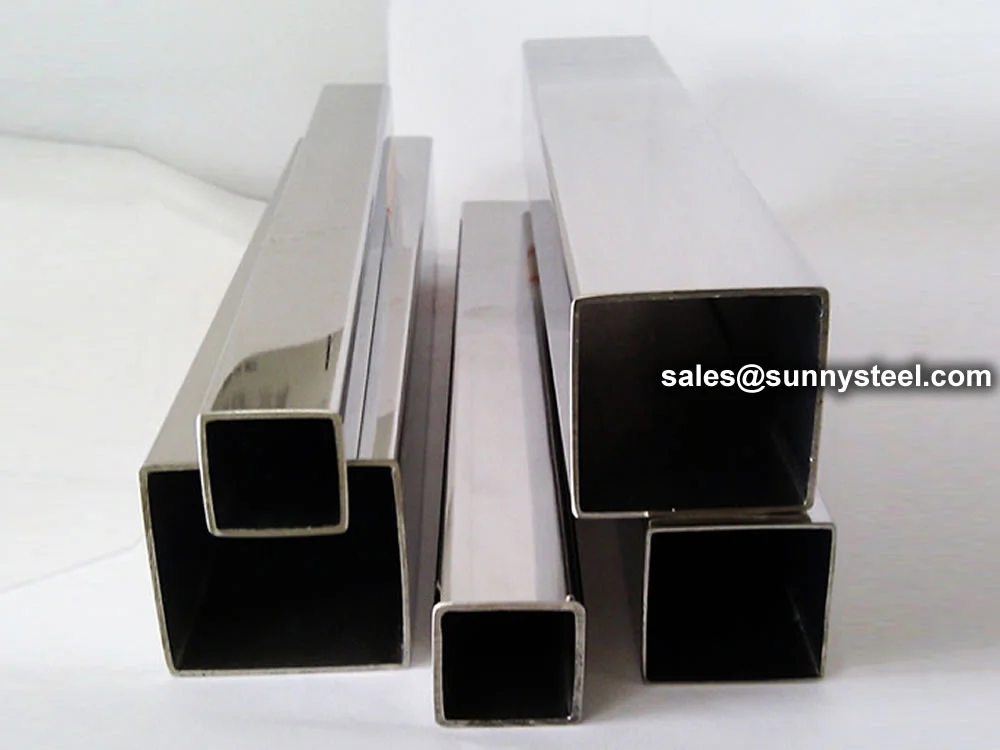

Manufactured through electric resistance welding (ERW) or seamless processes, Stainless Hollow Sections are available in sizes from 20x20 mm to 300x200 mm for square and rectangular profiles, with wall thicknesses from 1.0 to 12 mm. Surface finishes such as polished, brushed, or pickled enhance corrosion-resistant hollow sections for demanding environments. Standard lengths range from 6 to 12 meters, with customization available for specific project needs.

Rigorous testing, including tensile, hardness, and corrosion tests, ensures compliance with international standards. The high chromium and nickel content in grades like 316 provides superior resistance to pitting and crevice corrosion, making Stainless Hollow Sections ideal for harsh conditions in marine and food processing applications. Their aesthetic appeal and weldability support use in visible structures and medical equipment.

Compared to carbon steel hollow sections, Stainless Hollow Sections offer enhanced corrosion resistance and longevity, though at a higher cost. Their lightweight design and high strength-to-weight ratio make them suitable for automotive components and agricultural equipment, balancing performance and cost-effectiveness.

Stainless Hollow Sections address challenges like corrosion, structural integrity, and aesthetic requirements, providing reliable, high-performance solutions for diverse industrial and architectural applications.

Stainless Steel Square Box Section

Comparison of Stainless Hollow Sections with Carbon Steel SHS and Aluminum Profiles

| Feature |

Stainless Hollow Section |

Carbon Steel SHS |

Aluminum Profile |

| Material |

Stainless Steel (304/316) |

Carbon Steel (S235/S355) |

Aluminum (6061/6063) |

| Size Range |

20x20–300x200 mm |

20x20–400x400 mm |

10x10–300x200 mm |

| Corrosion Resistance |

Excellent |

Moderate (with coating) |

Good |

| Tensile Strength (MPa) |

515–690 |

360–630 |

200–310 |

| Cost |

Higher |

Cost-Effective |

Moderate |

Stainless Hollow Sections offer superior corrosion resistance compared to carbon steel hollow sections and aluminum profiles. Below is a comparison of key features.

Key Benefits

Superior Corrosion Resistance

High chromium and nickel content for harsh environments.

High Strength

Tensile strength up to 690 MPa for structural integrity.

Aesthetic Appeal

Polished or brushed finishes for architectural designs.

Versatile Sizes

Sizes from 20x20 to 300x200 mm for diverse applications.

Weldability

Easily welded for complex structural designs.

Standards Compliance

Meets ASTM A554, EN 10296, and ASTM A312 standards.