Corrosion-resistant And Aesthetic Tubing Solutions

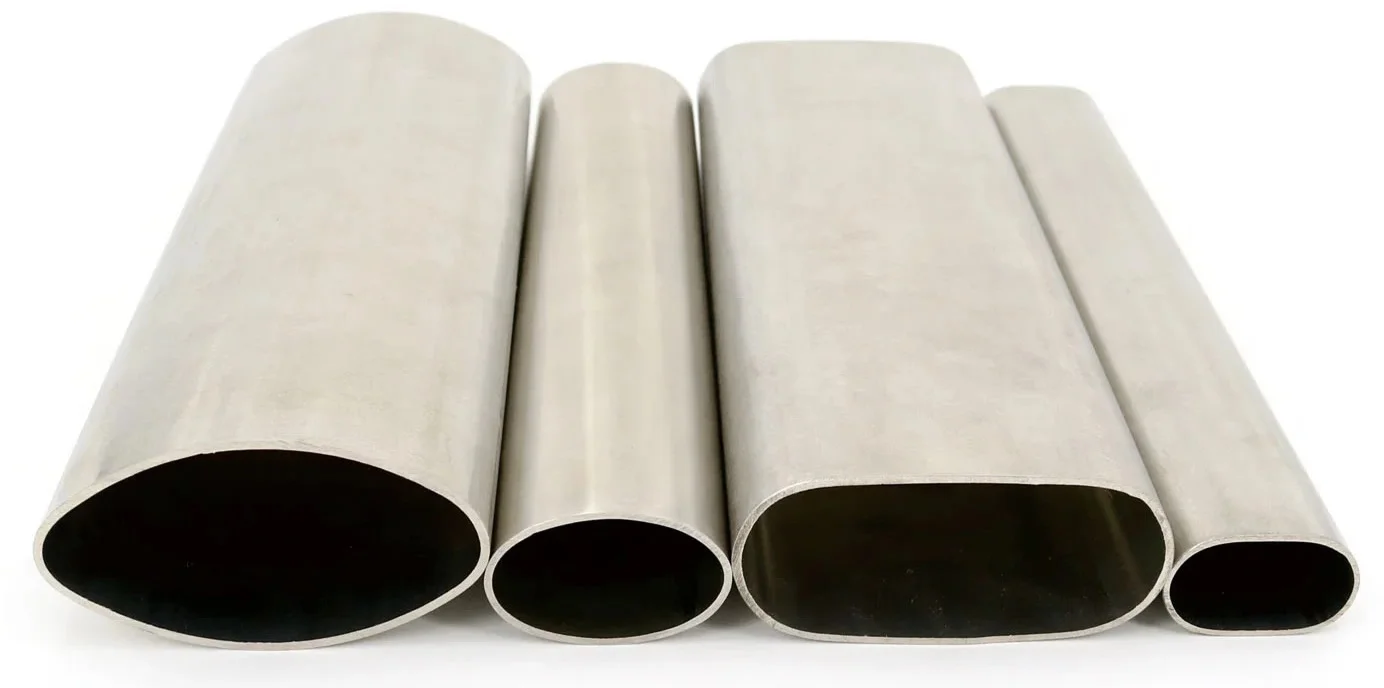

Stainless steel oval pipes offer corrosion resistance and aesthetic appeal for architectural, marine, and industrial applications.

Corrosion-resistant And Aesthetic Tubing Solutions

Stainless steel oval pipes offer corrosion resistance and aesthetic appeal for architectural, marine, and industrial applications.

D-shaped tube

Shaped tube railings, including oval, D-shaped, and radius square profiles, enhance aesthetics and ergonomics for handrails in various applications.

Oval tube handrails, available in sizes like 47 x 25 x 1.5mm and 61 x 37 x 2mm, and D-shaped tube handrails, typically in 50 x 18 x 1.5mm or 65 x 28 x 2mm, are crafted from stainless steel for a sophisticated appearance and ergonomic grip. The D-shaped profile, with its curved topside, is designed for comfortable and secure grasping, outperforming standard round tubes in both function and style.

Radius square tube, with gently contoured corners, serves as an elegant alternative for grab rails and boat railings on super yachts and tenders. These stainless steel profiles, compliant with standards like ASTM A554 and EN10219-1, offer corrosion resistance and durability. Surface finishes such as polished or mirror enhance their aesthetic appeal, making them ideal for architectural, marine, and structural applications.

Shaped tube railings combine style, comfort, and durability, providing premium solutions for modern handrail and railing systems.

Stainless Steel Oval Pipes are specialized stainless steel tubes with an elliptical cross-section, designed for both functional and decorative applications. Compliant with standards like ASTM A554, A269, and A312, these pipes are typically made from austenitic grades such as 304 and 316, offering tensile strengths of 485–515 MPa and exceptional corrosion resistance. They are ideal for architectural design, marine applications, and automotive exhaust systems.

Produced through seamless or welded processes like TIG or laser welding, Stainless Steel Oval Pipes are available in sizes with outer diameters from 9.5 mm to 108 mm and wall thicknesses from 0.5 to 2.0 mm. Surface finishes, including polished, brushed, or mirror finishes, enhance their aesthetic appeal and corrosion resistance, making them suitable for food processing equipment and furniture manufacturing. Standard lengths range from 5.8 to 12 meters, with custom lengths available.

Rigorous testing, including tensile, flattening, and corrosion tests, ensures compliance with standards. The high chromium (16–20%) and molybdenum (2–3% in 316 grades) content provides superior resistance to pitting and crevice corrosion, ideal for chemical processing and marine environments. Their oval shape offers better maneuverability in tight spaces compared to round pipes, supporting applications like railings and structural supports.

Compared to round stainless steel pipes, Stainless Steel Oval Pipes provide enhanced aesthetic appeal and directional strength, though they may have slightly lower pressure resistance. Their versatility, biocompatibility, and low maintenance make them a preferred choice for hygienic and high-corrosion environments, offering a balance of performance and cost-effectiveness.

Stainless Steel Oval Pipes address challenges like corrosion, space constraints, and aesthetic requirements, delivering reliable, high-performance solutions for diverse industrial and decorative applications.

Stainless steel and aluminium oval tube profiles are crafted to precise sizes and tolerances, ideal for specialized applications requiring unique shapes.

Can’t see the tube sizes you need in the table? Contact us about custom-sized tubing; we may able to fabricate a new size to meet your project requirements. Or download our brochure, which contains sizing information for existing aluminium and brass tubing too, as well as all stainless steel sizes.

Wall thickness tolerances are typically minimal, with variations that do not impact further fabrication or end use in most cases. However, for applications where precise tolerances are critical—such as when tubes must fit inside or house other components—customers should specify requirements before ordering. Compliance with standards like ASTM A554 and rigorous testing ensures durability and performance in demanding environments, such as construction or marine applications.

The oval tube profiles offer customized sizing and high precision, delivering aesthetic and functional solutions for specialized industrial needs.

The image above shows how dimensions are detailed (for example, 17mm x 17mm x 1.5mm)

Sizes given are for stainless steel.

| NOMINAL PIPE SIZE | OD (inches) | SCH 80 | SCH 5 | SCH 40 | SCH 10 |

|---|---|---|---|---|---|

| 3" | 3.5 | 0.3 | 0.083 | 0.216 | 0.12 |

| 1/2" | 0.84 | 0.147 | 0.065 | 0.109 | 0.083 |

| 2" | 2.375 | 0.218 | 0.083 | 0.154 | 0.109 |

| 3/4" | 1.05 | 0.154 | 0.065 | 0.113 | 0.083 |

| 3-1/2" | 4 | 0.318 | 0.083 | 0.226 | 0.12 |

| 1" | 1.315 | 0.179 | 0.065 | 0.133 | 0.109 |

| 2-1/2" | 2.875 | 0.276 | 0.083 | 0.203 | 0.12 |

| 1-1/4" | 1.66 | 0.191 | 0.065 | 0.14 | 0.109 |

| 4" | 4.5 | 0.337 | 0.083 | 0.237 | 0.12 |

| 1-1/2" | 1.9 | 0.2 | 0.065 | 0.145 | 0.109 |

Explore Stainless Steel Oval Pipes with targeted long-tail keywords for specifications, applications, and materials.

Note: Stainless Steel Oval Pipes meet international standards, ensuring high performance and reliability. Contact suppliers for detailed specifications.

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Stainless Steel Oval Pipe ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Stainless Steel Oval Pipe suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China (GB) | Japan (JIS) | American | Korea (KS) | EU (BS EN) | India (IS) | Australia (AS) | Taiwan (CNS) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New (07.10) | SUS | ASTM | UNS | STS | EN | IS | AS | CNS | |

| Austenitic Stainless Steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | — | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | — | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | — | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | — | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | — | — | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | — | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | — | — | STS316J1 | — | — | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | — | — | STS316J1L | — | — | — | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | — | — | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | — | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic-Ferritic Stainless Steel (Duplex) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | — | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | — | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | — | S31803 | STS329J3L | 1.4462 | — | 329J3L | 329J3L |

| Ferritic Stainless Steel | ||||||||||

| 25 | 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | — | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | — | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | — | — | STS410L | — | — | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | — | 434 | 434 |

| 30 | — | 022Cr18NbTi | — | — | S43940 | — | 1.4509 | — | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | — | 444 | 444 |

| Martensitic Stainless Steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | — | — | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | — | — | STS420J2 | 1.4028 | 30Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | — | — | 440A | 440A |

Stainless Steel Oval Pipe are engineered for high-strength and corrosion-resistant performance in automotive exhaust systems, construction frameworks, oil and gas pipelines, aerospace components, hydraulic systems, and chemical processing, meeting the demands of diverse industries including power generation and agricultural equipment.

efficient overseas shipping options

We specialize in international shipping for Stainless Steel Oval Pipe, ensuring safe and timely delivery worldwide.

Our clients come to us from across the globe for our unique shaped tubing and specialist tube fabrication. We can Stainless Steel Oval Pipe to North America and Europe in as little as soon as posible.

Our expert shipping team will meet your transit times and budget; get in touch to discuss transportation options.

Need help finding

Speak with one of our tube specialists to find out how best to integrate shaped tubing into your project. We can give you information on the best profile, metal, finish and dimensions for your application.

Our team is here to assist you in selecting the perfect size and shape for your specific needs.

Elliptic pipes offer corrosion resistance and aest...

Oval pipes offer corrosion resistance and aestheti...

Flat oval pipes offer corrosion resistance and aes...

Stainless hollow sections offer superior corrosion...

Rectangular hollow sections provide high-strength,...

Square hollow sections offer high-strength, corros...