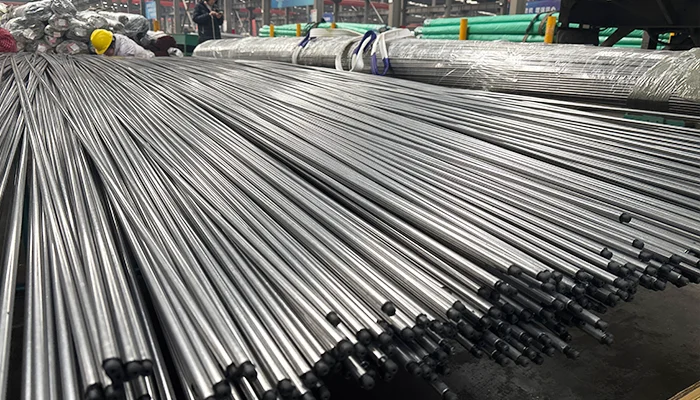

Galvanized Seamless Tubes are carbon steel tubes manufactured without welds and coated with

a zinc layer through hot-dip galvanizing, offering superior corrosion resistance and high strength.

Compliant with ASTM A53 and A123 standards, these tubes are ideal for water supply systems, oil and gas

pipelines, and structural frameworks, providing a minimum tensile strength of 415 MPa and a zinc coating

thickness of at least 1.5 oz/ft² (458 g/m²).

The seamless manufacturing process involves hot-rolling or cold-drawing steel billets, followed by immersion

in molten zinc at approximately 450°C (842°F), creating a metallurgical bond that protects against rust.

Available in sizes from DN15 (1/2”) to DN200 (8”) with wall thicknesses from SCH 40 to SCH 160, and lengths

from 5.8 to 12 meters, Galvanized Seamless Tubes meet diverse project requirements. Surface

treatments like passivation enhance longevity, and plain or threaded ends ensure easy installation.

These tubes undergo rigorous testing, including tensile, hydrostatic, and coating thickness tests, to ensure

compliance with ASTM standards. The zinc coating acts as a sacrificial anode, protecting the steel even if

scratched, making Corrosion-Resistant Seamless Tubes suitable for harsh environments like

marine and industrial settings. Their seamless construction ensures superior strength for high-pressure

applications in oil and gas pipelines and industrial piping.

Compared to welded galvanized tubes or stainless steel tubes, Galvanized Seamless Tubes

offer enhanced pressure resistance and durability, though they are more expensive than welded alternatives.

Their versatility and lifespan (up to 50 years) make them a preferred choice for structural and

high-pressure applications.

Galvanized Seamless Tubes address challenges like pipeline corrosion, high-pressure

demands, and environmental exposure, delivering reliable, long-lasting solutions for industrial and

residential applications.

EN 10305 Galvanized Hydraulic Seamless Steel Tube

Galvanized Hydraulic Tube

Galvanized hydraulic tube is a type of pipe commonly used for industrial

applications. The interior of the tube, as well as its ends, are typically coated in zinc.

This zinc coating helps to prevent corrosion from occurring which can damage the tube. While

many different types of tube exist, galvanized tube is one of the most common. The zinc

coating on the interior of the tube is an important factor to take into consideration when

choosing the right tube for your next application. Not all tubes are created equal and each

one offers its own unique benefits and flaws.

If you’re not familiar with the types of tubes that are available,

it can be difficult to know which one will be best suited for your application.

Why is Galvanized Tube Used?

Galvanized tube is used in many industrial applications due to its corrosion-resistant properties. Hydraulic

systems are particularly susceptible to corrosion due to the presence of oil and other fluids. This

corrosion can lead to serious system issues as well as breakdowns. Corrosion is a natural process that

occurs when certain materials come into contact with one another. When a product is placed within a

hydraulic system, it comes into contact with oil. If this oil is not kept clean, it can lead to corrosion.

The presence of rust and corrosion in a hydraulic system can lead to serious problems. Rust can build up

within the system and cause blockages. In more severe cases, it can lead to complete system failure.

Other Advantages of Galvanized Tubes

While corrosion resistance is the biggest advantage of using galvanized tubes, there are other benefits

associated with this type of tube that should be considered as well. One of the most common reasons to use

galvanized tubes is for the added strength that is offered. There are multiple different types of tubes that

are available. Some of these offer more strength than others. If you’re designing a new system or replacing

old components, it is important to consider the strength of each tube. If you’re designing a system that

needs to be able to withstand a significant amount of pressure, you will want to choose a stronger tube.

There are tubes that are designed to be stronger than others. If you’re looking for strength, it is

important to consider stronger tubes.

Drawbacks of Using Galvanized Tubes

There are many different types of tubes available for hydraulic systems; however, not all tubes are created

equal. Each tube has its own unique properties and features that make it suitable for certain applications

over others. When picking out the right tube, it is important to consider the benefits and drawbacks of each

type of tube to know which one is best suited for your application. While there are many different types of

tubes, it is important to note that not all of them will be suitable for all applications. If you’re in need

of a tube that can withstand a significant amount of pressure, galvanized tubes will not be suitable. If you

are not careful, galvanized tubes can be susceptible to corrosion, which can lead to serious issues in your

system. If you are in need of a tube that is corrosion-resistant, you will want to avoid galvanized tubes.

Conclusion

When it comes to choosing the right materials for your industrial applications, there are a number of

different factors to take into consideration. Whether you’re designing new machinery or replacing old

components, there are a number of details that must be evaluated when choosing the right materials. The type

and quality of material can have a significant impact on how an application performs, as well as its overall

longevity. When picking out the right materials, it is important to consider the benefits and drawbacks of

each type of material. The best materials are those that are corrosion-resistant and able to withstand a

significant amount of pressure without showing signs of weakness. When choosing materials for your next

project, it is important to pick out the right type of tube to ensure your system performs as intended.

Tube Color

The color of galvanized tube is typically a dull gray or silver. This is due to the zinc coating that is

applied to the interior of the tube.

Galvanized White Zinc Tube

Galvanized Yellow Zinc Tube

OD and Thickness Specifications (mm)

| OD (mm) |

Thickness (mm) |

| 1 |

1.5 |

2 |

2.5 |

3 |

3.5 |

4 |

4.5 |

5 |

6 |

8 |

| 6 |

6*1 |

6*1.5 |

6*2 |

|

|

|

|

|

|

|

|

| 8 |

8*1 |

8*1.5 |

8*2 |

|

|

|

|

|

|

|

|

| 10 |

10*1 |

10*1.5 |

10*2 |

|

|

|

|

|

|

|

|

| 12 |

12*1 |

12*1.5 |

12*2 |

12*2.5 |

|

|

|

|

|

|

|

| 14 |

14*1 |

14*1.5 |

14*2 |

14*2.5 |

14*3 |

|

|

|

|

|

|

| 15 |

15*1 |

15*1.5 |

15*2 |

15*2.5 |

15*3 |

|

|

|

|

|

|

| 16 |

16*1 |

16*1.5 |

16*2 |

16*2.5 |

16*3 |

|

|

|

|

|

|

| 18 |

|

18*1.5 |

18*2 |

18*2.5 |

18*3 |

18*3.5 |

18*4 |

|

|

|

|

| 20 |

|

20*1.5 |

20*2 |

20*2.5 |

20*3 |

20*3.5 |

20*4 |

|

|

|

|

| 22 |

|

22*1.5 |

22*2 |

22*2.5 |

22*3 |

22*3.5 |

22*4 |

|

|

|

|

| 25 |

|

|

25*2 |

25*2.5 |

25*3 |

25*3.5 |

25*4 |

|

|

|

|

| 28 |

|

|

28*2 |

28*2.5 |

28*3 |

28*3.5 |

28*4 |

|

|

|

|

| 30 |

|

|

30*2 |

30*2.5 |

30*3 |

30*3.5 |

30*4 |

30*4.5 |

30*5 |

|

|

| 32 |

|

|

32*2 |

32*2.5 |

32*3 |

32*3.5 |

32*4 |

32*4.5 |

32*5 |

|

|

| 34 |

|

|

34*2 |

34*2.5 |

34*3 |

34*3.5 |

34*4 |

34*4.5 |

34*5 |

34*6 |

|

| 35 |

|

|

35*2 |

35*2.5 |

35*3 |

35*3.5 |

35*4 |

35*4.5 |

35*5 |

35*6 |

|

| 38 |

|

|

38*2 |

38*2.5 |

38*3 |

38*3.5 |

38*4 |

38*4.5 |

38*5 |

38*6 |

|

| 40 |

|

|

|

40*2.5 |

40*3 |

40*3.5 |

40*4 |

40*4.5 |

40*5 |

40*6 |

|

| 42 |

|

|

|

42*2.5 |

42*3 |

42*3.5 |

42*4 |

42*4.5 |

42*5 |

42*6 |

|

| 45 |

|

|

|

45*2.5 |

45*3 |

45*3.5 |

45*4 |

45*4.5 |

45*5 |

45*6 |

|

| 46 |

|

|

|

46*2.5 |

46*3 |

46*3.5 |

46*4 |

46*4.5 |

46*5 |

46*6 |

|

| 48 |

|

|

|

48*2.5 |

48*3 |

48*3.5 |

48*4 |

48*4.5 |

48*5 |

48*6 |

|

| 50 |

|

|

|

50*2.5 |

50*3 |

50*3.5 |

50*4 |

50*4.5 |

50*5 |

50*6 |

|

| 54 |

|

|

|

|

54*3 |

54*3.5 |

54*4 |

54*4.5 |

54*5 |

54*6 |

|

| 60 |

|

|

|

|

60*3 |

60*3.5 |

60*4 |

60*4.5 |

60*5 |

60*6 |

60*8 |

Hot-Dip Galvanized Pipes offer distinct advantages over

pre-galvanized and stainless steel pipes. Below is a comparison of key features.

Outer Diameter Tolerance Specifications

| Outer Diameter |

Allowable Tolerance |

Special Tolerance |

| GB/T3639 |

DIN2391 |

OD |

WT |

| 4mm-20mm |

±0.10mm |

±0.08mm |

±0.05mm |

±0.05mm |

| 20mm-30mm |

±0.10mm |

±0.08mm |

±0.08mm |

±0.08mm |

| 31mm-40mm |

±0.15mm |

±0.15mm |

±0.10mm |

±0.08mm |

| 41mm-60mm |

±0.20mm |

±0.20mm |

±0.15mm |

±0.15mm |

| 61mm-80mm |

±0.30mm |

±0.30mm |

±0.20mm |

±0.20mm |

| 81mm-120mm |

±0.45mm |

±0.45mm |

±0.30mm |

±0.30mm |

Key Benefits

Corrosion Resistance

High chromium and molybdenum content for harsh environments.

Aesthetic Appeal

Polished or brushed finishes for decorative applications.

High Strength

Tensile strength up to 515 MPa for structural integrity.

Space Efficiency

Oval shape for tight spaces and better maneuverability.

Weldability

Easily welded for complex designs and installations.

Standards Compliance

Meets ASTM A554, A269, and A312 standards.