Cost-effective And Corrosion-resistant Piping Solutions

Pre-galvanized steel pipes offer cost-effective corrosion resistance for furniture, construction, and fencing applications.

Cost-effective And Corrosion-resistant Piping Solutions

Pre-galvanized steel pipes offer cost-effective corrosion resistance for furniture, construction, and fencing applications.

Pre-Galvanized Steel Pipes are carbon steel pipes coated with a zinc layer during the manufacturing process, offering cost-effective corrosion resistance. Compliant with ASTM A53 and A123 standards, these pipes are ideal for furniture manufacturing, construction frameworks, and fencing, providing a minimum tensile strength of 330 MPa and a zinc coating thickness of 0.6-1.0 oz/ft² (183-305 g/m²).

The pre-galvanizing process involves coating steel strips with zinc before forming them into pipes via electric resistance welding (ERW). This ensures uniform zinc coverage, though thinner than hot-dip galvanizing, making Pre-Galvanized Steel Pipes suitable for less corrosive environments. Available in sizes from DN15 (1/2”) to DN150 (6”) with wall thicknesses from 0.8 to 3.0 mm, and lengths from 5.8 to 12 meters, these pipes meet diverse project requirements. Surface treatments like passivation enhance durability, and threaded or plain ends facilitate easy installation.

These pipes undergo rigorous testing, including tensile, bending, and coating thickness tests, to ensure compliance with ASTM standards. The zinc coating provides a protective barrier against rust, making Corrosion-Resistant Steel Pipes suitable for indoor and mildly corrosive outdoor applications. Their lightweight design and welded construction support applications like greenhouse structures and automotive components.

Compared to hot-dip galvanized or stainless steel pipes, Pre-Galvanized Steel Pipes are more affordable but offer less robust corrosion resistance, requiring maintenance in harsh environments. Their versatility and lifespan (20-30 years) make them a preferred choice for light structural supports and cost-sensitive projects.

Pre-Galvanized Steel Pipes address challenges like corrosion, cost constraints, and structural versatility, delivering reliable solutions for industrial, residential, and agricultural applications.

Pre-galvanized steel pipe is a type of steel pipe that has been coated with a layer of zinc before it is formed into its final shape. This process provides corrosion resistance and enhances the durability of the pipe.

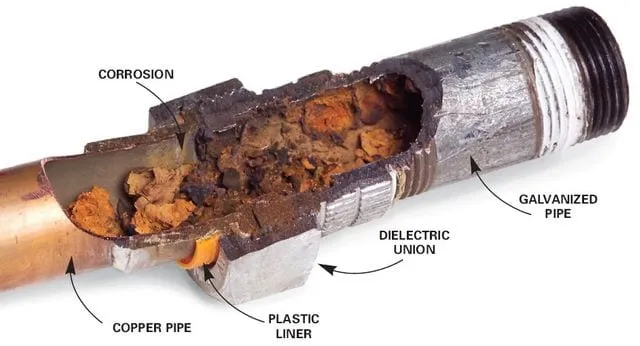

Steel tubes that are formed and galvanized afterwards are sometimes referred to as post-galvanized steel tubes, but hot-dipped steel tubes is a more commonly used expression.

Galvanized steel pipe or galvanized steel tube is the most popular type of galvanized steel tube manufacturing because the equipment required for manufacturing is relatively inexpensive and the process is highly scalable. Unlike hot-dip steel tube, the time required for galvanizing the steel sheet is short, so the alloy layer in which iron and zinc are mixed is small and the pure zinc layer is thick.

However, since the zinc applied to the steel sheet is removed by the heat upon welding the pre-galvanized steel tube, re-sealing the exposed steel on the outside surface with zinc thermal spray is a required post-treatment process. This also means that the welding seam on the inside of the steel tube is not galvanized. The sacrificial anode properties of zinc allow for leaving the inner welding seam exposed without reducing the corrosion resistance and longevity of the product.

Pre-galvanization, also known as mill galvanization, involves passing a steel sheet through molten zinc. After this process, the sheet is cut to the desired size and recoiled. During pre-galvanization, a specific thickness of zinc coating is applied to the entire sheet. For instance, pre-galvanized Z275 steel has a zinc coating of 275 grams per square meter. One notable advantage of pre-galvanized steel compared to hot-dip galvanized steel is its improved appearance. Additionally, it tends to be more cost-effective. Pre-galvanized materials find application in a wide range of products, including conduit, lip, and open channels.

As hot dipped galvanization requires dipping the whole steel/metals into the molten vat of zinc, the galvanized steel coming out from this process has a continuous coating over the surface. Pre-galvanizing is performed at the first stage before the sheets are cut into sizes and pieces so the cut edges are not coated.

Pre galvanized Rectangular tubes are the industry standard for fence framework, Contractors, architects, engineers. Architects and landscape architects have used steel fencing to design a variety of shelters, lighting standards and decorative sculptures for street-scapes, parks, bus and light rail stops, shopping centers, malls, sports stadiums, office buildings, parking lots and other facilities. Steel fence post are carefully designed with clean lines, structural integrity and ease of installation. These fences are available in variety of heights and widths in multiple configurations.

| ND | Outside Diameter (mm) | W.T. | Weight of Black Pipe (kg/m) | |||

|---|---|---|---|---|---|---|

| Nominal Size (DN) | Screw Identifiers | Maximum | Minimum | Thickness | Plain end pipe | Threaded and With Coupler |

| 15 | 1/2 | 21.4 | 21.0 | 2.0 | 0.947 | 0.956 |

| 20 | 3/4 | 26.9 | 26.4 | 2.3 | 1.38 | 1.39 |

| 25 | 1 | 33.8 | 33.2 | 2.6 | 1.98 | 2.00 |

| 32 | 11/4 | 42.5 | 41.9 | 2.6 | 2.54 | 2.57 |

| 40 | 11/2 | 48.4 | 47.8 | 2.9 | 3.23 | 3.27 |

| 50 | 2 | 60.2 | 59.6 | 2.9 | 4.08 | 4.15 |

| 65 | 21/2 | 76.0 | 75.2 | 3.2 | 5.71 | 5.83 |

| 80 | 3 | 88.7 | 87.9 | 3.2 | 6.72 | 6.89 |

| 100 | 4 | 113.9 | 113.0 | 3.6 | 9.75 | 10.0 |

The properties of galvanized steel are a unique combination that make it ideal for use in interior and exterior applications such as car bodies, appliances, nuts and bolts, roofs, and rebar.

| Grade | C (% max) | Mn (% max) | P (% max) | S (% max) | Cu (% max) |

|---|---|---|---|---|---|

| Grade A | 0.25 | 0.95 | 0.05 | 0.045 | 0.40 |

| Grade B | 0.30 | 1.20 | 0.05 | 0.045 | 0.40 |

The zinc coating (80-100 microns) enhances the corrosion resistance of Pre-Galvanized Steel Pipe , protecting the carbon steel base in harsh environments. The chemical composition ensures weldability and durability for

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) |

|---|---|---|---|

| Grade A | 330 | 205 | 28 |

| Grade B | 415 | 240 | 30 |

These properties ensure Pre-Galvanized Steel Pipe eliver robust performance in structural and high-pressure applications.

| Feature | Hot-Dip Galvanized Pipe | Pre-Galvanized Pipe | Stainless Steel Pipe |

|---|---|---|---|

| Coating | Zinc (80-100 microns) | Zinc (thinner, coil-coated) | None (inherent corrosion resistance) |

| Corrosion Resistance | Excellent (sacrificial anode) | Moderate (weaker at welds) | Superior (no coating needed) |

| Cost | Cost-effective | Lower initial cost | Higher cost |

| Lifespan | Up to 50 years | 20-30 years | 50+ years |

| Applications | Water, gas, construction | Light structural, fencing | Chemical, marine, hygienic |

Hot-Dip Galvanized Pipes offer distinct advantages over pre-galvanized and stainless steel pipes.

| Grade | C (% max) | Mn (% max) | Si (% max) | P (% max) | S (% max) | Cr (%) | Ni (%) | Mo (%) | N (% max) |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 | - | 0.10 |

| 304L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | - | 0.10 |

| 316 | 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

| 316L | 0.03 | 2.00 | 1.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10 |

The low carbon content in 304L and 316L enhances weldability, while molybdenum in 316 and 316L improves resistance to pitting and crevice corrosion, making Pre-Galvanized Steel Pipe ideal for harsh environments.

| Grade | Tensile Strength (min, MPa) | Yield Strength (min, MPa) | Elongation (min, %) | Hardness (max, HB) | Hardness (max, HRB) |

|---|---|---|---|---|---|

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

These mechanical properties make Pre-Galvanized Steel Pipe suitable for applications requiring high strength and corrosion resistance, such as architectural structures, marine environments, and chemical processing.

Galvanized seamless tubes are widely used in various industries, including construction, plumbing, automotive, and infrastructure projects.

Galvanized seamless tubes offer corrosion resistan...

Erw galvanized steel pipes offer corrosion resista...

Galvanized mild steel pipes offer corrosion resist...

Galvanized pipes for water offer corrosion resista...

Hot-dip galvanized square tubes offer corrosion re...