Robust Corrosion Protection For Industrial Applications

Single-layer anti-corrosion epoxy powder pipes offer robust corrosion resistance for oil, gas, water, and chemical applications.

Robust Corrosion Protection For Industrial Applications

Single-layer anti-corrosion epoxy powder pipes offer robust corrosion resistance for oil, gas, water, and chemical applications.

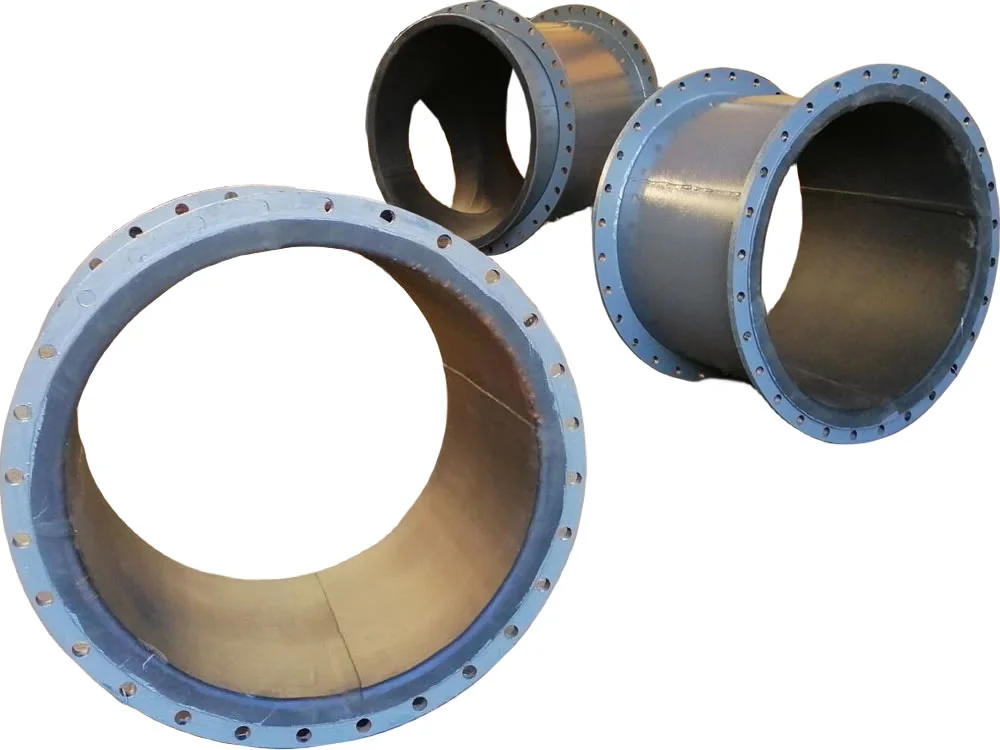

Single-Layer Anti-Corrosion Epoxy Powder Pipes are steel pipes coated with a fusion-bonded epoxy (FBE) layer, providing excellent resistance to corrosion in harsh environments. Compliant with standards like DIN 30670, ASTM A53, and AWWA C213, these pipes are ideal for oil and gas pipelines, water supply systems, and chemical processing plants, offering a minimum tensile strength of 415 MPa and an FBE coating thickness of 300-500 microns.

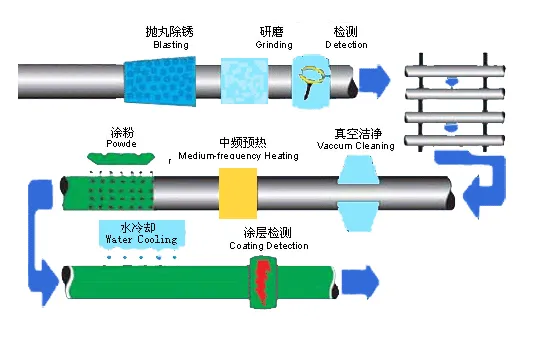

The FBE coating is applied through electrostatic spraying onto a preheated steel surface (~200-240°C), forming a hard, uniform layer with strong adhesion. Available in sizes from 20 mm to 1220 mm outer diameter, with wall thicknesses from 1 mm to 80 mm, and lengths in random, fixed, SRL, or DRL configurations, these FBE Coated Pipes meet diverse project needs. The coating process includes shot blasting and intermediate frequency preheating to ensure durability. Ends can be plain, beveled, or threaded, with protective caps or rings for installation ease.

Rigorous testing, including tensile, hydrostatic, and coating adhesion tests, ensures compliance with industry standards. The FBE layer provides superior resistance to chemicals like acids, alkalis, and salts, making Corrosion-Resistant Steel Pipes suitable for fire protection systems and wastewater treatment plants. The coating’s high mechanical strength and flexibility withstand bending and impact, ideal for HVAC systems.

Compared to multi-layer coatings like 3LPE or double-layer FBE, Single-Layer Anti-Corrosion Epoxy Powder Pipes are more cost-effective for applications with moderate corrosion risks, offering a lifespan of 20-30 years. They require periodic inspection in extreme conditions but provide reliable performance in most soil and fluid environments.

Single-Layer Anti-Corrosion Epoxy Powder Pipes address pipeline corrosion, chemical degradation, and mechanical wear, delivering durable, cost-efficient solutions for industrial piping systems.

Nearly 30 years ago, electrostatic spray epoxy powder coating was introduced, simplifying application, reducing pollution, and enhancing impact and high-temperature performance. This technology quickly gained traction in international markets.

Inspection: Hydraulic Testing, Eddy Current, Infrared Test;

The thired party, SGS, BV, can be accepted.

Certificate: Certificate: API 5L, API 5CT. ISO 9001; CE and so on.

Resistant to chemical corrosion, resistance to cathodic disbondment resistance, mechanical damage to properties.

| Feature | Single-Layer FBE Pipe | Double-Layer FBE Pipe | 3LPE Coated Pipe |

|---|---|---|---|

| Coating Type | Single-layer FBE (300-500 μm) | Double-layer FBE (≥620 μm) | Three-layer polyethylene |

| Corrosion Resistance | Excellent for moderate environments | Superior with enhanced mechanical protection | Excellent with additional insulation |

| Cost | Cost-effective | Higher cost | Highest cost |

| Lifespan | 20-30 years | 30-40 years | 40-50 years |

| Applications | Oil, gas, water, HVAC | Oil, gas, harsh environments | Buried pipelines, extreme conditions |

Single-Layer Anti-Corrosion Epoxy Powder Pipes offer distinct advantages over other coated and uncoated pipes.

FBE coating resists acids, alkalis, and salts effectively.

Up to 30 years with minimal maintenance.

Tensile strength up to 415 MPa for robust performance.

Threaded or beveled ends for seamless integration.

Affordable corrosion protection for moderate environments.

Meets DIN 30670, ASTM A53, and AWWA C213 standards.

| Standard | Description |

|---|---|

| GB/T3091 | Welded steel pipe for low pressure liquid delivery |

| GB/T9711 | Petroleum and natural gas industries -- Steel pipe for pipelines |

| IS: 3589 | Steel tubes for water and sewage |

| IS: 1978-1982 | Steel tubes for use in transportation of oil, gas, and petroleum products |

| ASTM A53 | Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

| DIN 2458 | Welded steel pipes and tubes |

| EN10217 | Welded steel tubes for pressure purposes. Technical delivery conditions. Non-alloy steel tubes with specified room temperature properties |

| API 5L | Line Pipe |

| SY/T5037 | Spiral submerged arc-welded steel pipe for pipelines for low pressure field fluid service |

| SY/T5040 | Spiral submerged arc-welded steel pipe piles |

| CJ/T3022 | Spiral submerged-arc welded steel pipe for municipal heat supply |

| ASTM A252 | Welded and seamless steel pipe piles |

The zinc coating (80-100 microns) enhances the corrosion resistance of Single-Layer Anti-Corrosion Epoxy Powder Pipe , protecting the carbon steel base in harsh environments. The chemical composition ensures weldability and durability for

| Standard | Description |

|---|---|

| ANSI/AWWA C104/A21.4 | American National Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water |

| ISO 21809 | Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems |

| DIN 30670 | Polyethylene coatings of steel pipes and fittings |

These standards ensure that Single-Layer Anti-Corrosion Epoxy Powder Pipe meet rigorous requirements for corrosion resistance, mechanical strength, and suitability for applications like oil and gas pipelines, water transmission, and chemical processing.

Single-Layer Anti-Corrosion Epoxy Powder Pipe typically refers to a type of polyethylene-coated steel pipe used in water distribution, drainage, and gas supply systems.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...

Hdpe (high-density polyethylene) lined steel pipe ...