Three-layer Polyethylene Coated Steel Pipes

3pe pipes offer superior corrosion resistance for oil, gas, water, and chemical applications in extreme environments.

Three-layer Polyethylene Coated Steel Pipes

3pe pipes offer superior corrosion resistance for oil, gas, water, and chemical applications in extreme environments.

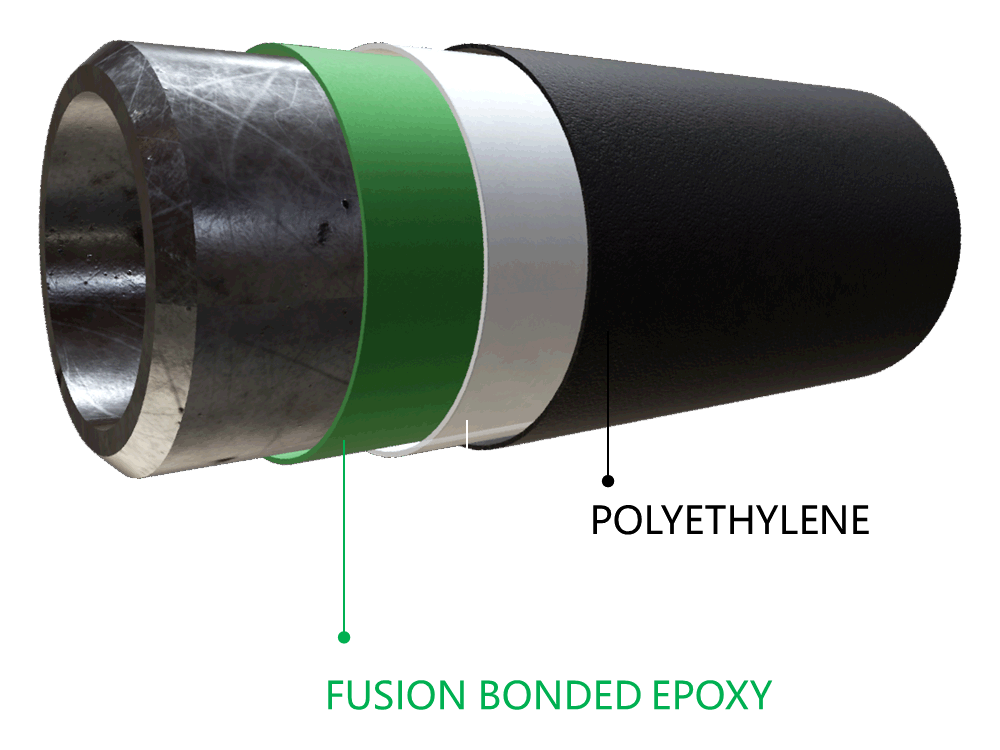

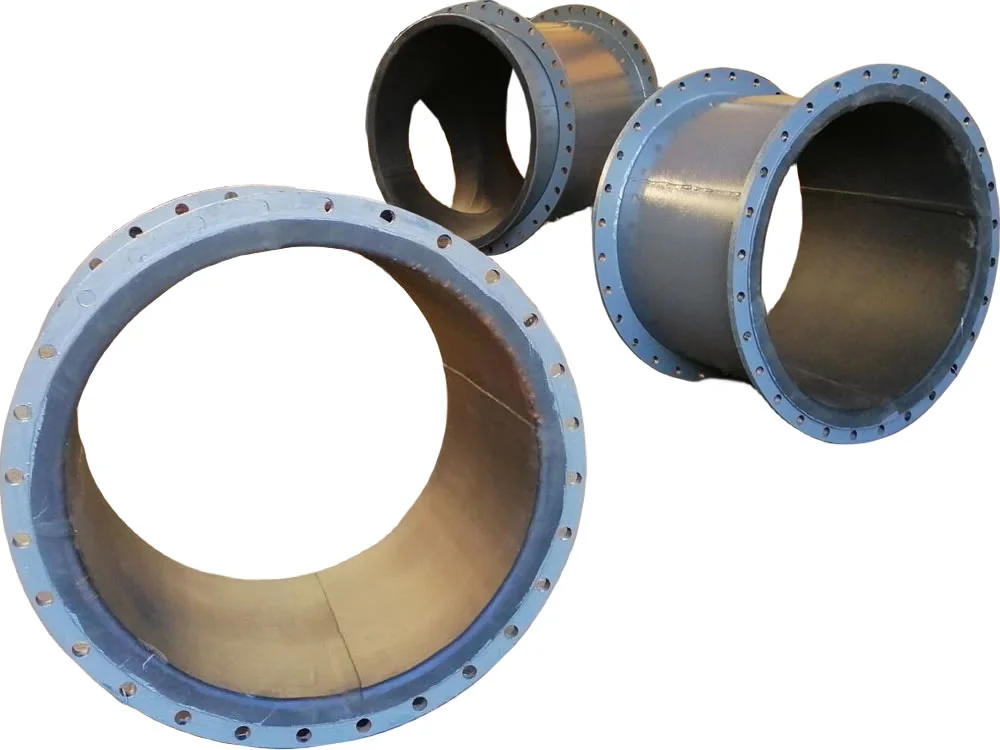

3PE Pipes are steel pipes coated with a three-layer polyethylene system, consisting of a fusion-bonded epoxy (FBE) base (150-300 µm), an adhesive layer (170-250 µm), and a polyethylene outer layer (1.8-3.7 mm), designed for superior corrosion resistance in extreme environments. Compliant with DIN 30670, ISO 21809-1, and SY/T0413-2002 standards, these pipes are ideal for oil and gas pipelines, water transmission systems, and chemical processing plants, offering a minimum tensile strength of 415 MPa.

The coating process involves surface preparation via shot blasting (Sa 2.5 cleanliness), followed by FBE application, adhesive extrusion, and polyethylene coating at ~200-240°C. Available in sizes from OD 159 mm to 2020 mm, wall thicknesses from 5 mm to 25 mm, and lengths of 6 m, 12 m, or customized up to 18 m, Three-Layer Polyethylene Pipes meet diverse project needs. Ends are plain, beveled, or threaded, with protective caps or rings for transport and installation.

Rigorous testing, including peel strength (≥100 N/cm at 20°C), impact resistance (≥7 J/mm coating thickness), and holiday detection (25 kV), ensures compliance with industry standards. The FBE layer provides chemical resistance, the adhesive ensures strong bonding, and the polyethylene offers mechanical protection against abrasion and corrosion, making Corrosion-Resistant Pipes suitable for underground and marine pipelines.

Compared to 2PE or single-layer FBE pipes, 3PE Pipes offer enhanced protection for severe conditions, with a lifespan of 40-50 years. They are ideal for buried pipelines and industrial fluid transport but may have higher costs due to the multi-layer coating. Regular inspections are recommended in highly abrasive environments.

3PE Pipes address pipeline corrosion, mechanical wear, and environmental degradation, delivering robust, long-lasting solutions for critical infrastructure and industrial applications.

3PE Pipes offer superior protection compared to other coated and uncoated pipes. Below is a comparison of key features.

| Feature | 3PE Pipe | 2PE Pipe | Single-Layer FBE Pipe |

|---|---|---|---|

| Coating Type | FBE + Adhesive + Polyethylene (2.2-4.5 mm) | Adhesive + Polyethylene (2-4.5 mm) | Single-layer FBE (300-500 μm) |

| Corrosion Resistance | Superior for extreme environments | Excellent for moderate conditions | Good for mild environments |

| Cost | Higher cost | Moderate cost | Cost-effective |

| Lifespan | 40-50 years | 30-40 years | 20-30 years |

| Applications | Oil, gas, water, underground pipelines | Oil, gas, sewage, marine | Water, HVAC, fire protection |

3PE (Three-Layer Polyethylene) coating is an advanced anti-corrosion technology for steel pipes, comprising three layers:

3PE coated pipes are widely used in industries like oil and gas, water supply, and chemical pipelines due to their exceptional durability and performance.

The 3PE coating provides excellent protection against corrosion, preventing rust and extending the lifespan of steel pipes, even in aggressive environments such as underground or underwater installations.

3PE pipes withstand mechanical stress, abrasion, and impact. The coating provides extra protection during transportation, installation, and operation, making them ideal for harsh conditions.

The polyethylene coating can handle temperatures from -40°C to +80°C, making 3PE pipes suitable for both low and high-temperature environments.

The 3PE coating resists acids, alkalis, and other aggressive substances, making these pipes ideal for chemical and industrial applications.

3PE pipes are environmentally friendly and meet safety standards, preventing leaks and ensuring contaminants do not pollute the surrounding environment.

These pipes are easy to install and require minimal maintenance due to their durable, long-lasting coating, reducing maintenance costs over time.

While offering superior protection, 3PE pipes are relatively affordable, providing long-term savings by reducing the need for frequent repairs and replacements.

3PE pipes are versatile and can be used in water pipelines, oil and gas transportation, and chemical industry systems.

The polyethylene coating provides excellent thermal insulation, preventing heat loss during fluid transport and ensuring energy efficiency in high-temperature applications.

3PE pipes are highly resistant to mechanical stress, abrasion, and impact, making them ideal for harsh environments where physical damage is a concern. The coating provides extra protection against external forces during transportation, installation, and operation.

Explore 3PE Pipes with targeted long-tail keywords for specifications, applications, and materials.

Note: 3PE Pipes meet international standards, ensuring high performance and durability. Contact suppliers for detailed specifications.

| Standard | Description |

|---|---|

| GB/T3091 | Welded steel pipe for low pressure liquid delivery |

| GB/T9711 | Petroleum and natural gas industries -- Steel pipe for pipelines |

| IS: 3589 | Steel tubes for water and sewage |

| IS: 1978-1982 | Steel tubes for use in transportation of oil, gas, and petroleum products |

| ASTM A53 | Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

| DIN 2458 | Welded steel pipes and tubes |

| EN10217 | Welded steel tubes for pressure purposes. Technical delivery conditions. Non-alloy steel tubes with specified room temperature properties |

| API 5L | Line Pipe |

| SY/T5037 | Spiral submerged arc-welded steel pipe for pipelines for low pressure field fluid service |

| SY/T5040 | Spiral submerged arc-welded steel pipe piles |

| CJ/T3022 | Spiral submerged-arc welded steel pipe for municipal heat supply |

| ASTM A252 | Welded and seamless steel pipe piles |

The zinc coating (80-100 microns) enhances the corrosion resistance of 3PE pipe , protecting the carbon steel base in harsh environments. The chemical composition ensures weldability and durability for

| Standard | Description |

|---|---|

| ANSI/AWWA C104/A21.4 | American National Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water |

| ISO 21809 | Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems |

| DIN 30670 | Polyethylene coatings of steel pipes and fittings |

These standards ensure that 3PE pipe meet rigorous requirements for corrosion resistance, mechanical strength, and suitability for applications like oil and gas pipelines, water transmission, and chemical processing.

3PE pipe typically refers to a type of polyethylene-coated steel pipe used in water distribution, drainage, and gas supply systems.

Rubber lined pipes offer superior abrasion and cor...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...

Hdpe (high-density polyethylene) lined steel pipe ...