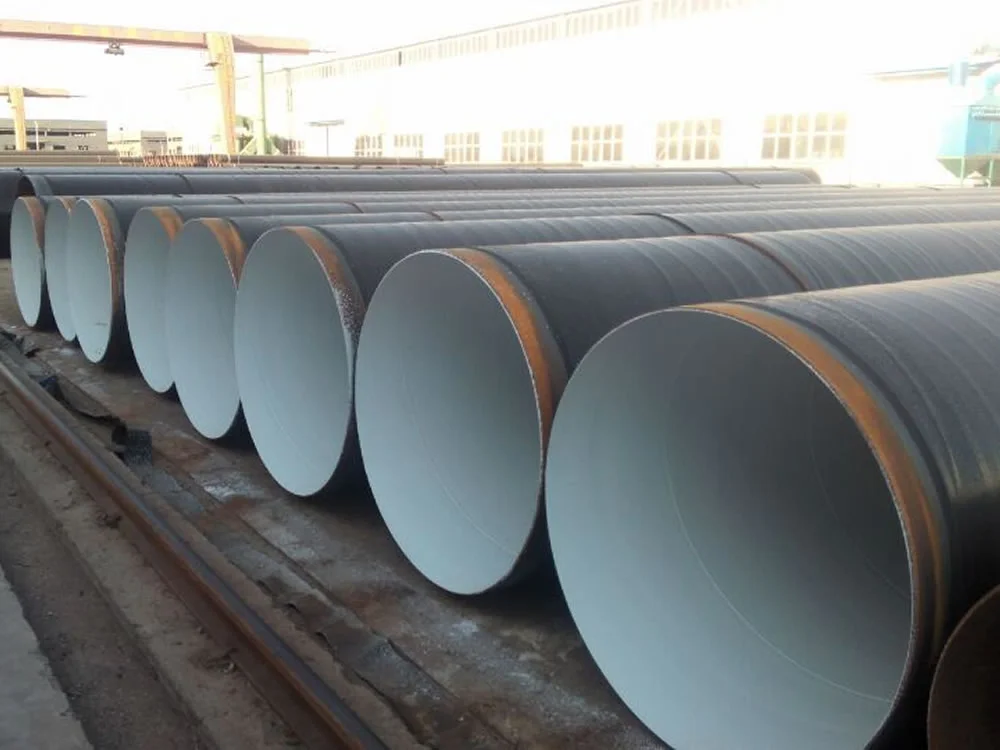

Anticorrosion Steel Pipes For Water And Industrial Use

Ipn 8710 coating consists of polyurethane resin and modified epoxy resin and asphalt, anti-rust pigments and additives such as grinding precision filtration.

Anticorrosion Steel Pipes For Water And Industrial Use

Ipn 8710 coating consists of polyurethane resin and modified epoxy resin and asphalt, anti-rust pigments and additives such as grinding precision filtration.

IPN8710 Pipes are advanced steel pipes coated with a specialized interpenetrating polymer network (IPN) system, combining polyurethane resin, modified epoxy resin, asphalt, non-toxic anti-rust pigments, and additives for superior corrosion resistance. This coating, compliant with AWWA C210 and C213 standards, integrates the benefits of epoxy and polyurethane coatings while overcoming their limitations, making it ideal for potable water pipelines, oil and gas transmission, and industrial fluid transport.

IPN8710 anti-corrosion steel pipe is composed of two-component, high-solid paint with epoxy resin as the main agent, divided into primer and top coat. The primer is composed of polyurethane polyethylene, modified epoxy resin, etc. It is cured at room temperature to form an interpenetrating network, with dense coating film structure, acid, alkali and salt resistance, excellent rustproof performance and strong adhesion; the top coat is composed of epoxy, rubber resin modified, etc., with excellent chemical resistance, non-toxicity, and resistance to microbial erosion.

The IPN8710 coating consists of a primer (40-60 µm) for adhesion and corrosion protection, and a finish layer (40-60 µm) for mechanical strength and impermeability, with a total thickness of ≥200 µm for standard applications and ≥250 µm for enhanced conditions. The epoxy component ensures strong bonding to the steel surface, excellent cathodic disbondment, and low water absorption, while the polyurethane enhances flexibility and resistance to hydrolysis. The asphalt and additives improve impermeability and durability, forming a dense, non-toxic coating safe for potable water.

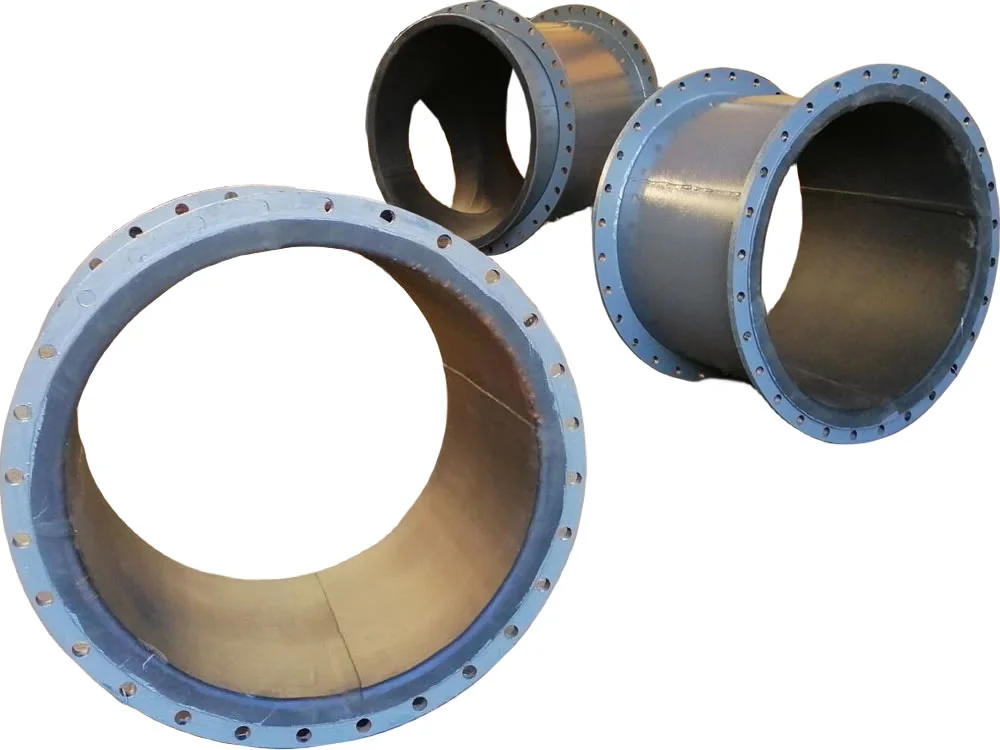

Manufactured via ERW, SAW, or seamless processes, IPN8710 Pipes undergo abrasive blasting (Sa 2.5, ~30 µm profile) before coating application via spraying, brushing, or rolling. Available in diameters from 325 mm to 2220 mm, wall thicknesses from 3 mm to 15.6 mm, and lengths up to 12 meters or customized, these pipes meet diverse project needs. Rigorous testing, including adhesion (Grade 1), impact resistance (≥50 cm), and flexibility (1 mm), ensures durability in harsh environments like petrochemical plants and marine pipelines.

Compared to 3PE or FBE pipes, IPN8710 Pipes offer a cost-effective, non-toxic solution with a service life of 30-50 years, excellent thermal insulation (25% of traditional pipe heat loss), and suitability for direct burial in underground or water environments, including frozen soil, without requiring a ditch. Regular inspections are recommended in highly corrosive settings to maintain performance.

IPN8710 Pipes address pipeline corrosion, microbial erosion, and mechanical wear, providing reliable, energy-efficient solutions for critical infrastructure, with high sealing, low maintenance costs, and environmental protection.

| Component | Composition | Function |

|---|---|---|

| Polyurethane Resin | Primary component in primer and finish | Provides flexibility and hydrolysis resistance |

| Modified Epoxy Resin | Core component in primer and finish | Ensures adhesion and corrosion resistance |

| Asphalt | Additive in coating | Enhances impermeability and durability |

| Anti-Rust Pigments | Non-toxic pigments in primer and finish | Prevents oxidation and rust formation |

| Additives | Fillers and performance enhancers | Improves application and coating performance |

The IPN8710 coating forms a robust, interpenetrating network, ensuring low water permeability (<0.01%), strong adhesion, and resistance to acids, alkalis, salts, and microbial erosion, ideal for potable water and industrial applications.

| Property | Primer | Finish |

|---|---|---|

| Viscosity (25±1°C, s) | 60–80 | 60–100 |

| Fineness (µm) | ≤80 | ≤80 |

| Solids Content (%) | >70 | >75 |

| Surface Drying Time (25±1°C, h) | ≤1 | ≤1 |

| Whole Drying Time (25±1°C, h) | ≤24 | ≤24 |

| Adhesion (Grade) | 1 | 1 |

| Flexibility (mm) | 1 | 1 |

| Impact Resistance (cm) | ≥50 | ≥50 |

| Hardness | ≥0.5 | ≥0.5 |

| Coating Thickness (µm) | 40–60 | 40–60 |

These properties ensure IPN8710 Pipes deliver high corrosion resistance, mechanical strength, and durability across a wide temperature range (-40°C to 100°C).

IPN8710 Pipes combine the advantages of epoxy and polyurethane coatings, offering a cost-effective, non-toxic alternative to 3PE and FBE pipes.

| Feature | IPN8710 Pipe | 3PE Pipe | FBE Pipe |

|---|---|---|---|

| Coating Type | IPN8710 (Polyurethane + Epoxy + Asphalt) | FBE + Adhesive + Polyethylene | Single-layer FBE |

| Corrosion Resistance | Excellent, non-toxic for potable water | Superior for extreme environments | Good for mild environments |

| Cost | Cost-effective | Higher cost | Cost-effective |

| Lifespan | 30-50 years | 40-50 years | 20-30 years |

| Applications | Potable water, oil, gas, sewage | Oil, gas, water, underground | Water, HVAC, fire protection |

Why Choose IPN8710 Pipes? They offer a non-toxic, cost-effective solution with excellent corrosion resistance and versatility for potable water and industrial applications.

IPN8710 Anticorrosive Spiral Steel Pipe

The 8710 anticorrosive spiral steel pipe (SSAW steel pipe) involves applying a liquid epoxy coating, IPN8710 anticorrosion, to the inner wall of the spiral pipe.

This coating, composed of polyurethane prepolymer, epoxy resin, and other components, is commonly utilized for daily drinking water and food transportation due to its corrosion resistance, hydrolysis resistance, and other advantageous properties. This article will talk about anticorrosive spiral steel pipe.

Explore IPN8710 Pipes with targeted long-tail keywords for specifications, applications, and materials.

Note: IPN8710 Pipes meet AWWA standards, ensuring high performance and safety. Contact suppliers for detailed specifications.

IPN8710 Pipe typically refers to a type of polyethylene-coated steel pipe used in water distribution, drainage, and gas supply systems.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...

Hdpe (high-density polyethylene) lined steel pipe ...