Three-layer Polypropylene Coated Pipes For Extreme Environments

3pp pipes offer superior corrosion and temperature resistance for oil, gas, water, and industrial applications, ensuring durability in harsh environments.

Three-layer Polypropylene Coated Pipes For Extreme Environments

3pp pipes offer superior corrosion and temperature resistance for oil, gas, water, and industrial applications, ensuring durability in harsh environments.

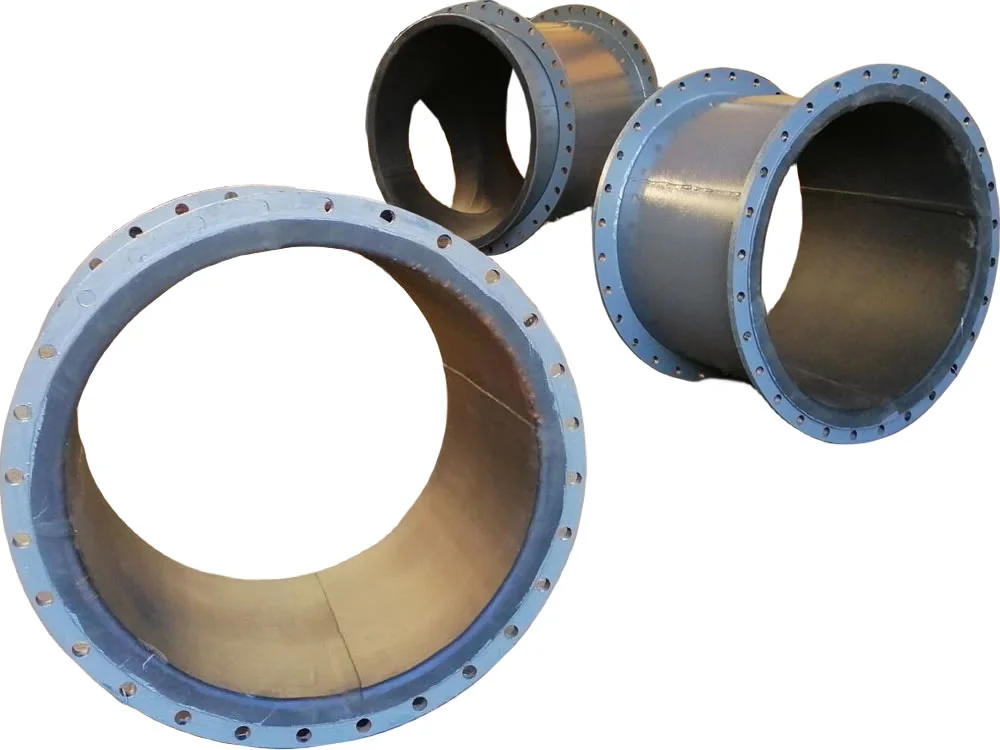

3PP Pipes, also known as Three-Layer Polypropylene Coated Pipes, are advanced steel pipes with a multilayer coating system designed for superior corrosion resistance and mechanical protection in high-temperature environments. Comprising a fusion-bonded epoxy (FBE) primer, a copolymer adhesive, and a high-density polypropylene (PP) topcoat, these pipes comply with standards like DIN 30678, ISO 21809-1, and CSA Z245.21, making them ideal for oil and gas pipelines, water infrastructure, and chemical industries.

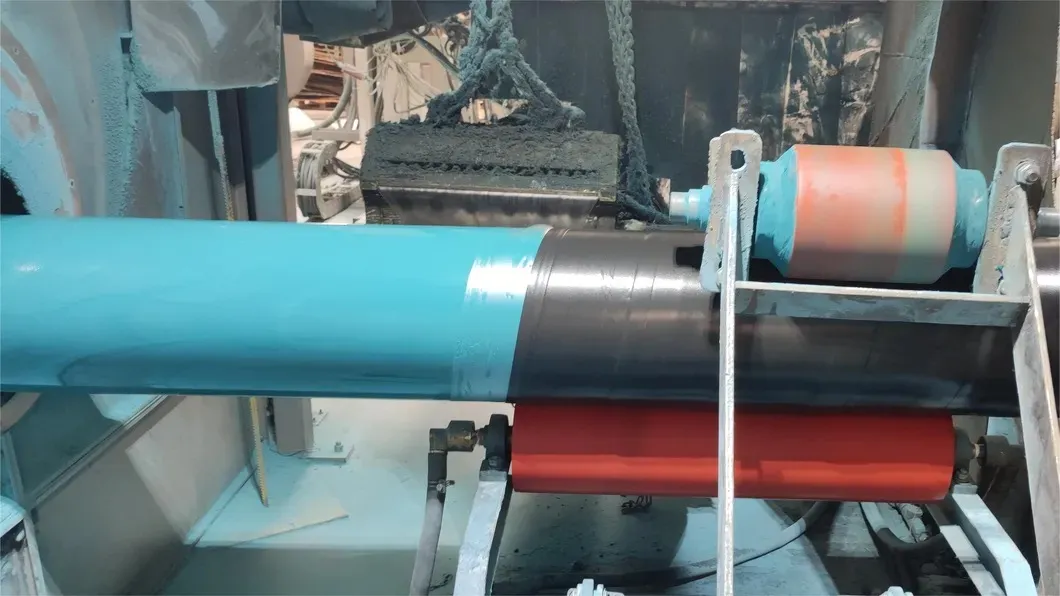

The 3PP coating is applied after abrasive blasting (Sa 2.5, ~30 µm profile) to ensure optimal adhesion. The FBE primer (10 mils minimum) provides corrosion protection, the adhesive layer (8 mils minimum) ensures bonding, and the polypropylene topcoat (40 mils minimum) offers exceptional mechanical strength and temperature resistance up to 140°C. Available in diameters from 114.3 mm to 3020 mm, wall thicknesses from 5 mm to 60 mm, and lengths up to 12 meters or customized, 3PP Pipes meet diverse project requirements.

These Anticorrosion Steel Pipes excel in harsh conditions, such as offshore pipelines, deepwater applications, and high-temperature fluid transport, due to their resistance to abrasion, chemical attack, and cathodic disbondment. Rigorous testing, including impact strength (>7 J/mm), peel strength (≥18 N/mm at 23°C), and cathodic disbondment (≤5 mm at 23°C), ensures compliance with international standards. The coating’s UV resistance and low maintenance requirements enhance longevity, with a service life exceeding 75 years in optimal conditions.

Compared to 3PE pipes, 3PP Pipes offer superior temperature resistance (up to 140°C vs. 80°C for 3PE) and mechanical protection, making them suitable for extreme environments like rocky terrains or deep-sea pipelines. Their eco-friendly, non-toxic properties also support applications in water supply systems, reducing environmental risks from leaks.

3PP Pipes address critical challenges like pipeline corrosion, mechanical wear, and thermal stress, providing reliable, cost-effective solutions for long-distance oil and gas transmission, water distribution, and industrial fluid transport.

The polypropylene outer layer provides superior mechanical protection, resisting impact, abrasions, and other external stresses.

The epoxy primer and adhesive ensure excellent corrosion protection, making 3PP pipes suitable for environments exposed to moisture, chemicals, or soil corrosion.

Polypropylene is highly resistant to UV radiation, making these pipes ideal for aboveground applications where exposure to sunlight could otherwise degrade the material.

3PP pipes can last more than 50 years, even in harsh environmental conditions, ensuring reliable long-term performance.

3PP pipes can handle a wide range of temperatures, ensuring reliable performance in both cold and hot climates.

With their superior protection against corrosion and mechanical damage, 3PP pipes last longer than many other types of pipes, reducing replacement and maintenance costs.

The polypropylene outer layer provides enhanced protection from impacts and environmental stress, making these pipes suitable for both underground and aboveground applications.

The epoxy primer and adhesive layers provide excellent protection from corrosion, ensuring the long-term durability of the pipeline.

3PP pipes can handle extreme temperatures and exposure to UV radiation, making them versatile in a variety of climates and environments.

While the initial cost may be higher, the longer lifespan and reduced maintenance requirements of 3PP pipes result in overall cost savings over time.

| Layer | Material | Function |

|---|---|---|

| Fusion-Bonded Epoxy (FBE) Primer | Epoxy powder | Provides corrosion protection and adhesion to steel |

| Copolymer Adhesive | Polymeric adhesive | Bonds FBE to polypropylene topcoat |

| Polypropylene Topcoat | High-density polypropylene | Ensures mechanical strength, temperature resistance, and UV protection |

The 3PP coating forms a robust, multilayer system with a total thickness of 2.0–4.7 mm, depending on pipe mass, ensuring excellent resistance to corrosion, abrasion, and high temperatures.

| Property | Value | Test Condition |

|---|---|---|

| Total Coating Thickness | 1.3–4.7 mm | Depends on pipe mass (Pm ≤15 to >300 kg/m) |

| Strain at Break | ≥400% | 23°C ± 3°C |

| Stress at Yield | ≥15.0 MPa | 23°C ± 3°C |

| Impact Strength | >7 J/mm | 23°C ± 3°C |

| Peel Strength | ≥18 N/mm | 23°C |

| Cathodic Disbondment | ≤5.0 mm | 23°C, 28 days, -1.38V |

| Indentation Resistance | ≤0.2 mm | 23°C |

| Flexibility | No cracking | 2.0° per pipe diameter length |

| UV Resistance | △MFR ≤35% | Standard exposure |

| Temperature Range | -40°C to 140°C | Design operating conditions |

These properties ensure 3PP Pipes provide exceptional durability, mechanical protection, and corrosion resistance in extreme conditions.

3PP Pipes offer distinct advantages over 3PE and FBE pipes, particularly in high-temperature and mechanically demanding environments.

| Feature | 3PP Pipe | 3PE Pipe | FBE Pipe |

|---|---|---|---|

| Coating Type | FBE + Adhesive + Polypropylene | FBE + Adhesive + Polyethylene | Single-layer FBE |

| Temperature Range | -40°C to 140°C | -40°C to 80°C | -40°C to 85°C |

| Corrosion Resistance | Excellent, high chemical resistance | Excellent, good for humid environments | Good for mild environments |

| Mechanical Protection | Superior, ideal for rocky terrains | Good, suitable for general use | Moderate, less abrasion-resistant |

| Cost | Higher cost, justified by performance | Cost-effective | Most cost-effective |

| Lifespan | >75 years | 40-50 years | 20-30 years |

Why Choose 3PP Pipes? They provide unmatched temperature and mechanical resistance, ideal for extreme conditions, with a longer lifespan than 3PE or FBE pipes.

| Nominal Diameter (mm) | Inner Coating Layer (mm) | Outer Coating Layer (mm) | |

|---|---|---|---|

| Ordinary Level | Strengthen Level | ||

| DN ≤ 65 | > 0.3 | > 0.6 | > 0.8 |

| 65 ≤ DN ≤ 150 | > 0.35 | > 0.8 | > 1.0 |

| 150 ≤ DN ≤ 300 | > 0.35 | > 0.8 | > 1.2 |

| 300 ≤ DN ≤ 800 | > 0.4 | > 1.0 | > 1.3 |

| 800 ≤ DN ≤ 1200 | > 0.45 | > 1.2 | > 1.8 |

| 1200 ≤ DN ≤ 3600 | > 0.45 | > 1.5 | > 1.8 |

| Note: Can be customized according to customer requirements. | |||

3PP Anticorrosive Steel Pipe with Polypropylene Anticorrosive Coating

3PP coating is mainly used as anti-corrosion pipeline for conveying higher temperature media and as anti-corrosion layer for pipeline in desert areas with high surface temperature and long sunshine time, so it has been more and more widely used in buried water, gas and oil pipelines in areas with high surface temperature and long sunshine time.

Explore 3PP Pipes with targeted long-tail keywords for specifications, applications, and materials.

Note: 3PP Pipes meet international standards for high-performance applications. Contact suppliers for detailed specifications.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

Pipe cement mortar lining provides durable corrosi...

Hdpe (high-density polyethylene) lined steel pipe ...