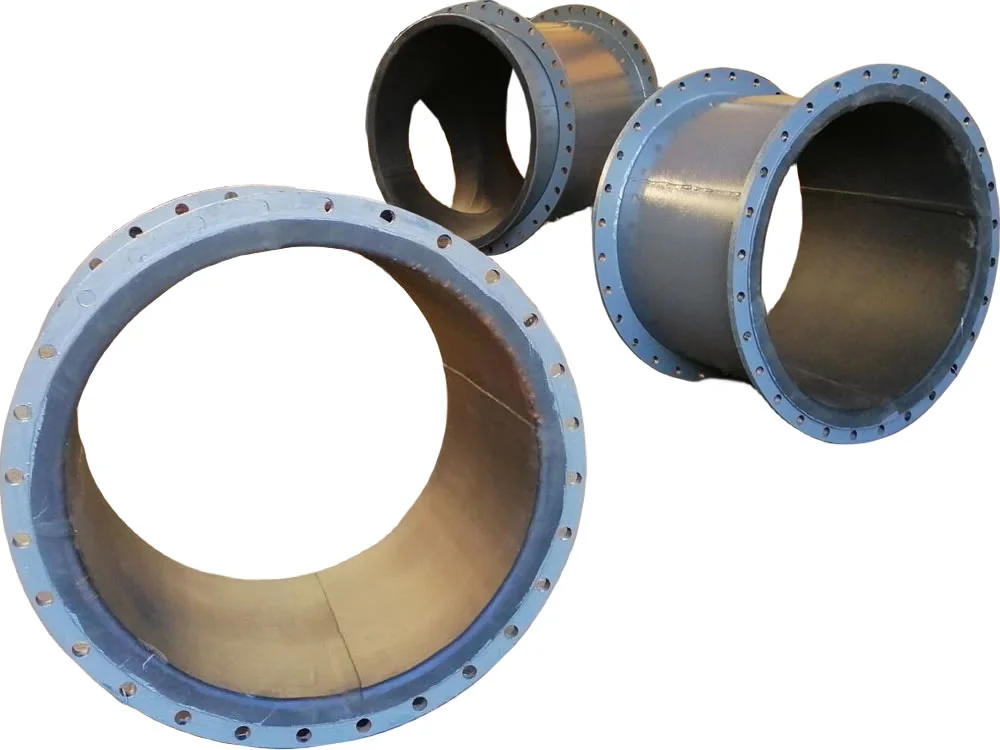

Corrosion-resistant Lining For Water And Sewage Pipelines

Pipe cement mortar lining provides durable corrosion protection and hydraulic efficiency for water, sewage, and industrial pipelines, extending service life up to 100 years.

Corrosion-resistant Lining For Water And Sewage Pipelines

Pipe cement mortar lining provides durable corrosion protection and hydraulic efficiency for water, sewage, and industrial pipelines, extending service life up to 100 years.

Pipe Cement Mortar Lining is a proven corrosion protection solution applied to the interior of steel and ductile iron pipes, widely used for potable water, raw water, sewage, and industrial fluid transport. Compliant with AWWA C205 and ANSI/AWWA C104/A21.4 standards, this lining consists of a Portland cement mortar mixture, offering exceptional durability and hydraulic efficiency.

The cement mortar is applied centrifugally to straight pipe sections, creating a dense, smooth surface that reduces tuberculation and improves flow characteristics (Hazen-Williams coefficient ~140). For fittings and flanges, hand-troweling or spraying ensures uniform coverage. The lining, typically 1/8” to 1/2” thick, provides a high pH barrier (~12.5) that passivates the steel or iron surface, preventing corrosion. Pipes are available in diameters from 4” to 120” for shop-applied linings and larger for field-applied linings per AWWA C602, with lengths up to 12 meters or customized.

Cement Lined Pipes undergo rigorous testing, including compressive strength (≥4,000 psi), adhesion, and hydrostatic tests, ensuring compliance with industry standards. The lining’s autogenous healing property allows it to self-repair minor cracks when exposed to water, enhancing longevity (50–100 years). Suitable for temperatures up to 212°F (150°F with asphaltic coating), these pipes resist corrosion from aggressive water, sewage, and low-velocity fluids (<20 ft/s).

Compared to other coatings like FBE or 3PE, Pipe Cement Mortar Lining is cost-effective, non-toxic, and ideal for potable water systems. It adds structural stiffness, reducing deflection under external loads, and requires minimal maintenance. Careful handling during storage and installation is essential to prevent lining damage, with recommended use of cushioned slings and proper support.

Pipe Cement Mortar Lining addresses pipeline corrosion, tuberculation, and flow inefficiencies, providing reliable, eco-friendly solutions for municipal water systems, sewage treatment, and industrial applications, ensuring safe and efficient fluid transport.

Cement-mortar lining is a process used to coat the interior of pipes, typically made of steel or ductile iron, with a cement-mortar mixture to protect them from corrosion and improve flow characteristics. This lining acts as a barrier between the water and the pipe wall, preventing tuberculation (a type of corrosion that reduces pipe capacity) and enhancing flow efficiency. It also increases the pipe's resistance to external loads and deflection.

Internal Cement Lining

Internal cement lining is a method that is corrosion-resistant in nature, and it is used for pipe lining, tank lining and many other equipment. Nowadays this service is used in the chemical processing factory, oil sector, gas sector and also used in water supply sectors.

Internal cement lining involves applying a specially formulated cement-based material to the interior of steel or concrete pipes. This lining acts as a protective barrier, preventing direct contact between the pipe material and corrosive substances, such as water, chemicals, or wastewater. By isolating the pipe’s interior surface, it significantly reduces wear and corrosion, ensuring long-term durability in applications like water supply, sewage systems, and industrial pipelines.

Internal Cement Lining – on specially formulated cement-based material applied to steel or concrete pipes. The lining serves as a protective coating in which the pipe material and any materials that corrode shall not come in direct contact. In a nutshell, it is a protective barrier that does not allow pipes to get worn out and keeps them in working condition for various years to come.

Internal cement lining creates a protective layer that resists water, chemicals, and air corrosion, ensuring long-term pipeline integrity.

By preventing corrosion, cement lining extends service life, especially in oil and gas pipelines, reducing maintenance and replacement costs.

The smooth inner lining reduces friction, allowing fluids and gases to travel more efficiently in water supply and oil pipelines.

While initial costs may be higher, cement lining saves money long-term by improving efficiency, lowering energy use, and extending pipe life.

Cement lining resists a wide range of chemicals, making it ideal for aggressive industrial environments and ensuring pipeline integrity.

By preventing leaks and bursts, cement lining protects the environment from contamination, especially in petrochemical and mining applications.

Pipe Cement Mortar Lining typically refers to a type of polyethylene-coated steel pipe used in water distribution, drainage, and gas supply systems.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Hdpe (high-density polyethylene) lined steel pipe ...