High-density Polyethylene Lining For Pipeline Durability

Hdpe (high-density polyethylene) lined steel pipe combines the strength and rigidity of steel with the corrosion resistance and chemical inertness of hdpe.

High-density Polyethylene Lining For Pipeline Durability

Hdpe (high-density polyethylene) lined steel pipe combines the strength and rigidity of steel with the corrosion resistance and chemical inertness of hdpe.

HDPE Lined Pipe combines the mechanical strength of steel or concrete with the corrosion and abrasion resistance of high-density polyethylene (HDPE), offering a robust solution for water, oil, gas, and industrial pipelines. Compliant with standards like AWWA C906 and ASTM F3508, these pipes feature a tight-fitting HDPE liner inserted into a host pipe to protect against internal corrosion and wear.

The High-Density Polyethylene Lining is typically installed using the Tite Liner® or CompressionFit™ process, where an HDPE liner with a slightly larger outer diameter is pulled through a reduction die and inserted into the host pipe. Once tension is released, the liner expands to form a tight, friction-fit seal against the inner wall, creating a seamless barrier. Available in diameters from 2” to 72” and lengths up to 3,000 feet per pull, these pipes suit both new installations and rehabilitation projects.

Corrosion-Resistant Pipes undergo rigorous testing, including hydrostatic pressure, tensile strength, and pull-out resistance tests, ensuring compliance with ASTM F1545. The HDPE liner’s smooth surface (Manning’s n ~0.009) enhances flow efficiency, reducing friction and pumping costs. With a design life of 50–100 years, these pipes resist chemicals, acids, and abrasive materials like slurries, making them ideal for harsh environments.

Compared to cement mortar or epoxy linings, HDPE Lined Pipes offer superior flexibility, abrasion resistance, and ease of installation, especially in trenchless applications. They require minimal maintenance and eliminate the need for corrosion inhibitors, providing an eco-friendly alternative to traditional pipeline replacement. Proper handling and UV protection during storage are recommended to maintain liner integrity.

HDPE Lined Pipes address pipeline corrosion, abrasion, and leakage, offering cost-effective, durable, and sustainable solutions for municipal, oil and gas, mining, and industrial systems, ensuring reliable fluid transport in extreme conditions.

High density polyethylene is now used in a wide range of piping applications – from tailings pipe to municipal water service. Spence Corrosion can supply all your requirements for minor repairs and flange replacement to full pipeline installations. Our expertise will ensure your project is on time and on budget.

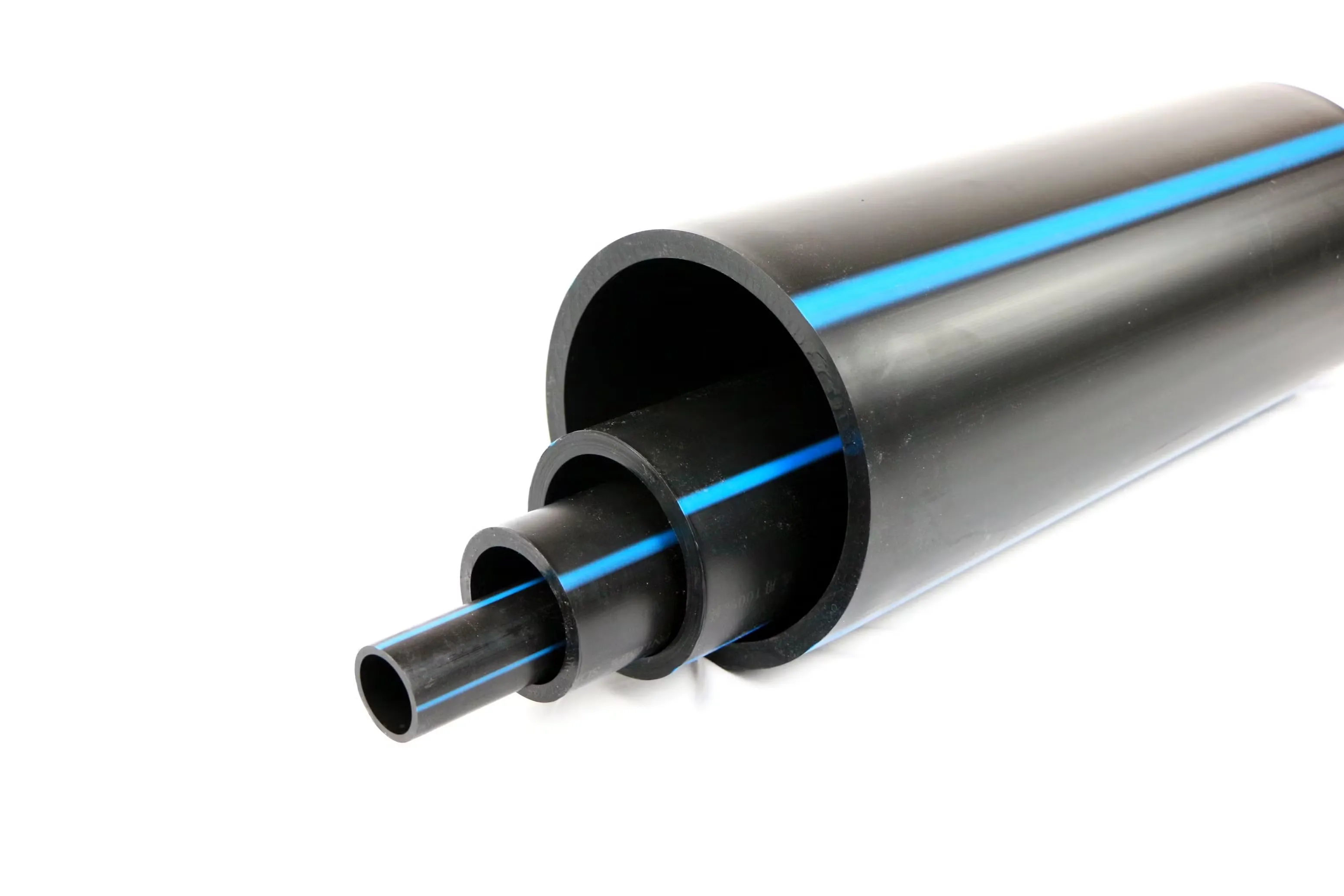

HDPE Pipe

High-density polyethylene jacket tube is widely used in oil pipelines, gas pipelines, urban heating pipes

HDPE pipes, made from high-density polyethylene, are lightweight, flexible, and resistant to corrosion and chemical degradation. They are extensively used in oil pipelines, gas pipelines, and urban heating systems, offering reliable performance in demanding environments. Manufactured through an extrusion process, these pipes provide excellent strength-to-weight ratios and are available in various sizes and pressure ratings to meet project requirements.

HDPE pipe ideal suitable for many different applications, including municipal, industrial, energy, geothermal, landfill and so on. HDPE pipe strength, durability, flexibility, weight of light welding after the high density polyethylene to zero leakage rate, because the welding process formed a whole HDPE system.

HDPE pipes provide versatile, eco-friendly, and long-lasting solutions for fluid and gas transport in critical infrastructure projects.

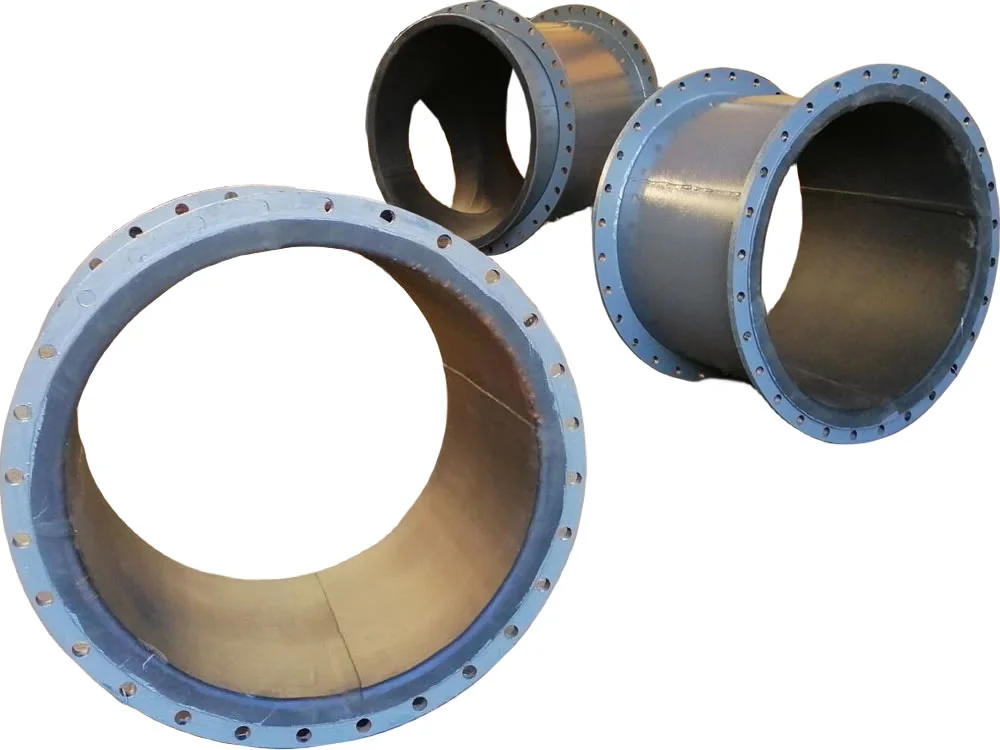

HDPE Lined Pipe Fittings

HDPE Lined Pipe Fittings, and short straight sections of steel pipe are often needed to terminate the pipeline, or for use in areas where larger radius bends cannot be accommodated.

The steel pipe spools, or fittings, are fabricated with weld neck flanges to connect with the HDPE-lined steel pipeline.

Concrete is heavy and brittle. Avoid bumps or shocks to prevent cracks or edge damage during handling.

Use a 150mm sling at the pipe’s center of gravity. Ensure the pipe rests on its barrel, not the socket.

Prepare trench and bedding as per engineer’s specification. Remove socket-end space so pipe lies horizontally on barrel.

Place rubber ring on the spigot end at locating groove. Ensure equal tension using a screwdriver around the barrel.

Align spigot into socket while suspended. Use lever or tirfor system to pull pipes together before lowering onto bedding.

Compact soil beneath pipe curvature to create a strong foundation. Follow engineer’s specification for long-term strength.

Discover HDPE Lined Pipes with targeted long-tail keywords for specifications, applications, and rehabilitation solutions.

Note: HDPE Lined Pipes meet ASTM, AWWA, and ISO standards, ensuring reliable performance. Contact suppliers for detailed specifications.

Epoxy Powder

Adhesion

Polyethylene / Polypropylene

Cement Inside

API 5L (PSL1, PSL2)

GB/T 9711.1

Gr. B, X42, X46, X52, X60, X65, X70, X80

Q235B; Gr. C

SAW

SSAW

HSAW

Hydraulic Testing

Eddy Current

Infrared Test

Third Party: SGS, BV accepted

API 5L

API 5CT

ISO 9001

CE, and more

HDPE Lined Pipe typically refers to a type of polyethylene-coated steel pipe used in water distribution, drainage, and gas supply systems.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...