Advanced Corrosion Protection For Industrial Pipelines

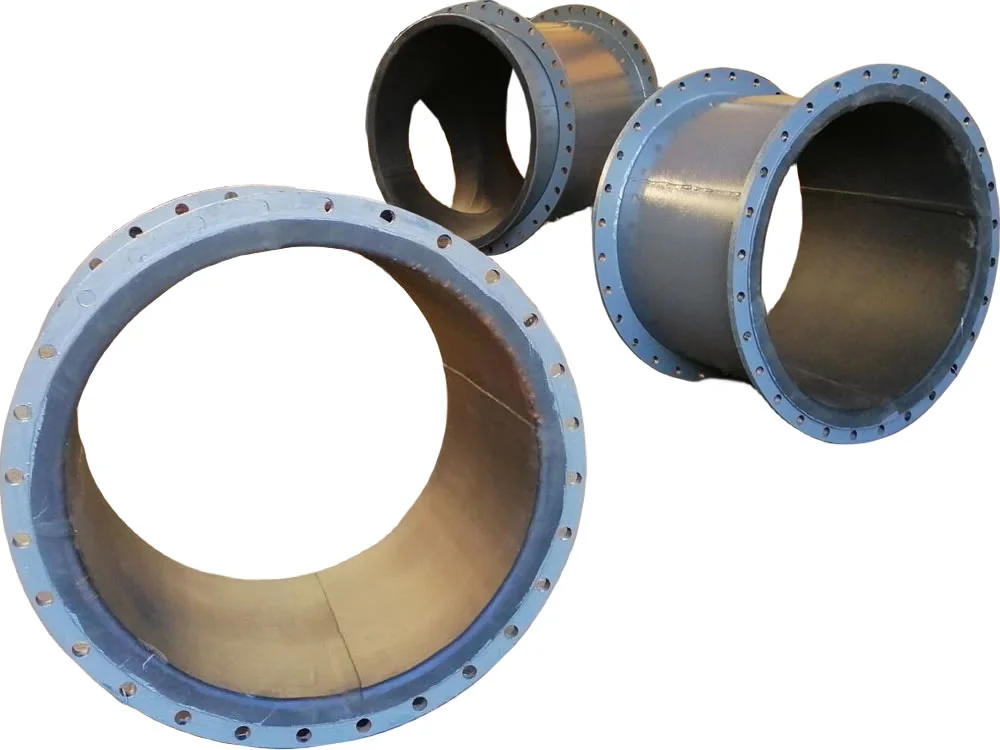

Internal coating pipes protect against corrosion and abrasion in water, oil, gas, and chemical pipelines, ensuring durability and flow efficiency.

Advanced Corrosion Protection For Industrial Pipelines

Internal coating pipes protect against corrosion and abrasion in water, oil, gas, and chemical pipelines, ensuring durability and flow efficiency.

Internal Coating Pipes are steel or alloy pipes coated internally with protective layers like Fusion Bonded Epoxy (FBE) or Liquid Epoxy, designed to prevent corrosion, enhance flow efficiency, and extend service life in demanding applications. Compliant with standards like NACE SP0394 and ISO 21809, these pipes are ideal for water, oil, gas, and chemical pipelines.

The Fusion Bonded Epoxy Coating is applied as a powder to preheated pipes (180–250°C), melting to form a uniform, durable barrier. Liquid Epoxy Coating is sprayed or brushed, curing at ambient or controlled temperatures. Both methods ensure excellent adhesion and resistance to chemicals and abrasion. Available in diameters from 2” to 48” and thicknesses from 100–500 microns, these coatings suit diverse pipeline requirements.

Corrosion Protection Pipes undergo rigorous testing, including holiday detection, adhesion, and cathodic disbondment tests, ensuring compliance with industry standards. The smooth coating surface (Ra ~0.5–2.5 µm) reduces friction, improving flow efficiency and reducing pumping costs. These coatings resist temperatures up to 120°C (FBE) or 80°C (Liquid Epoxy), making them suitable for harsh environments like oilfields and chemical plants.

Compared to HDPE linings or cement mortar, Internal Coating Pipes offer superior chemical resistance and easier application for complex geometries. They require minimal maintenance, reducing downtime and operational costs. Surface preparation via abrasive blasting (to Sa 2.5) ensures optimal coating adhesion, while proper curing prevents defects like pinholes or blisters.

Internal Coating Pipes address pipeline corrosion, abrasion, and fouling, providing reliable, cost-effective, and eco-friendly solutions for industrial piping systems, ensuring longevity and performance in extreme conditions.

| Component | FBE Coating (%) | Liquid Epoxy Coating (%) | Function |

|---|---|---|---|

| Epoxy Resin | 60–80 | 50–70 | Provides adhesion and chemical resistance |

| Hardener/Curing Agent | 10–20 | 20–30 | Ensures curing and durability |

| Fillers (Silica, Talc) | 10–20 | 5–15 | Enhances mechanical strength |

| Pigments/Additives | 2–5 | 2–10 | Improves UV and thermal stability |

The Internal Coating Pipes utilize epoxy-based coatings for robust corrosion and chemical resistance in industrial applications.

| Property | FBE Coating | Liquid Epoxy Coating | Test Standard |

|---|---|---|---|

| Adhesion Strength | ≥30 MPa | ≥20 MPa | ASTM D4541 |

| Hardness (Shore D) | 80–90 | 70–85 | ASTM D2240 |

| Impact Resistance | ≥1.5 J | ≥1.0 J | ASTM G14 |

| Chemical Resistance | Excellent (pH 2–12) | Good (pH 3–11) | ASTM D543 |

| Temperature Range | -30°C to 120°C | -20°C to 80°C | N/A |

| Surface Roughness (Ra) | 0.5–2.5 µm | 1.0–3.0 µm | ISO 4287 |

These properties ensure Internal Coating Pipes provide robust corrosion protection and flow efficiency in demanding environments.

Internal Coating Pipes with FBE or Liquid Epoxy outperform HDPE linings and cement mortar in chemical resistance and ease of application.

| Feature | FBE Coating | Liquid Epoxy Coating | HDPE Lining | Cement Mortar Lining |

|---|---|---|---|---|

| Material | Epoxy powder | Liquid epoxy | High-density polyethylene | Cement, sand |

| Corrosion Resistance | Excellent | Good | Superior, chemically inert | Good, high pH |

| Abrasion Resistance | Good | Moderate | Excellent | Moderate |

| Application Method | Electrostatic spray | Spray/brush | Trenchless insertion | Centrifugal/spray |

| Temperature Range | Up to 120°C | Up to 80°C | Up to 80°C | Up to 60°C |

| Lifespan | 20–30 years | 15–25 years | 50–100 years | 50–100 years |

Provides excellent corrosion resistance and is widely applied in oil and gas pipelines for long-term durability.

Offers good flexibility and impact resistance, making it suitable for pipelines subject to mechanical stress.

Designed for high-temperature applications, providing exceptional thermal stability and protection.

Known for its superior chemical resistance, ideal for pipelines in aggressive industrial environments.

With over 30 years of proven use, epoxy powder coating offers a simple, economical, and eco-friendly anti-corrosion solution. It ensures long service life and excellent performance for oil, gas, and water pipelines.

Widely applied in oil & gas pipelines, product lines, and fire-fighting systems. Provides ecological safety, maintains water quality, and ensures reliability in long-term operations.

Epoxy-based heat-resistant coatings are applied inside steel pipes and dried using hot air or water above 60°C. Ideal for hot water and heating pipelines, ensuring durability under thermal stress.

Combines epoxy resin latex with cement mortar, reinforced with colloidal silica. Provides excellent corrosion protection and mechanical strength for water, oil, gas, and steam pipelines.

Internal Coating Pipes typically refers to a type of polyethylene-coated steel pipe used in water distribution, drainage, and gas supply systems.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...