Durable Rubber Lining For Industrial Pipeline Protection

Rubber lined pipes offer superior abrasion and corrosion resistance for mining, chemical, and wastewater pipelines, ensuring durability and cost-efficiency.

Durable Rubber Lining For Industrial Pipeline Protection

Rubber lined pipes offer superior abrasion and corrosion resistance for mining, chemical, and wastewater pipelines, ensuring durability and cost-efficiency.

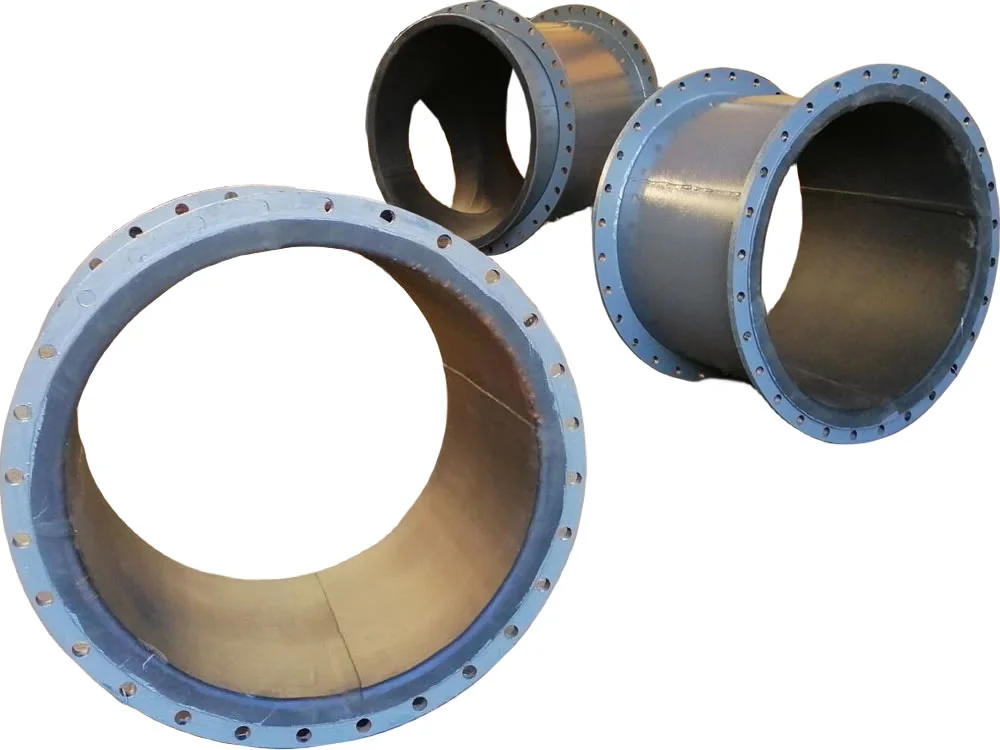

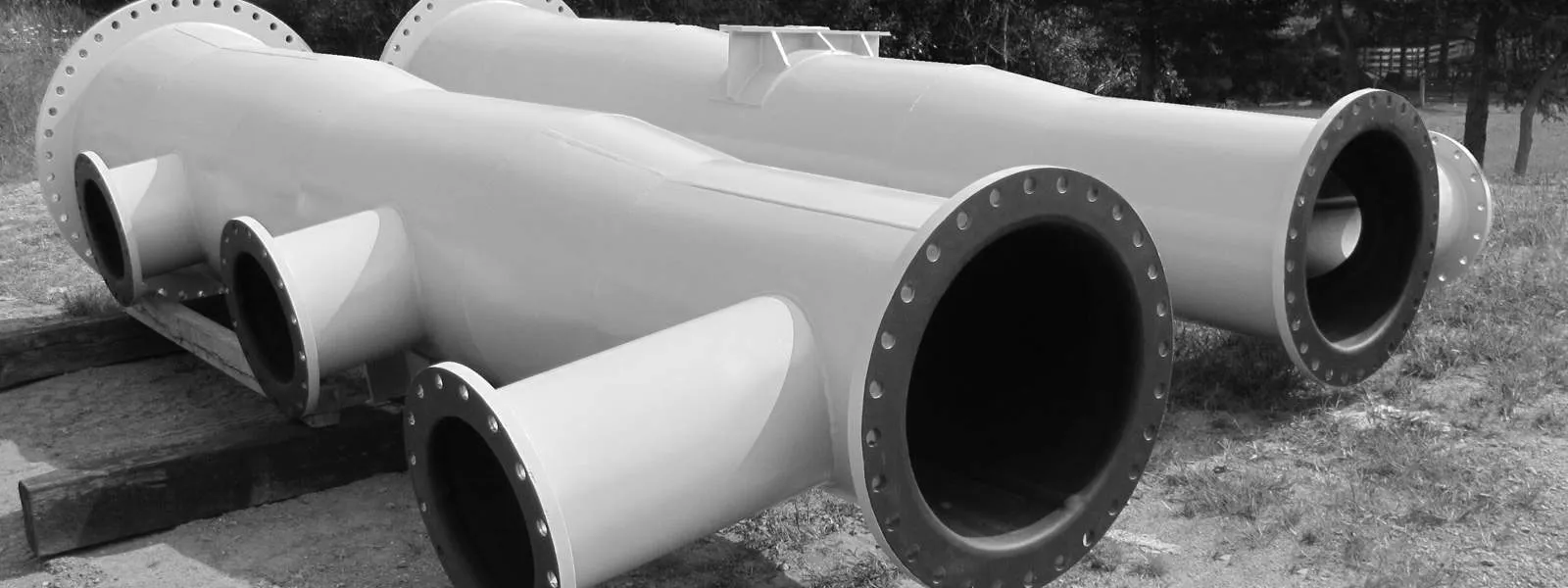

Rubber Lined Pipes are steel or alloy pipes internally lined with natural or synthetic rubber, designed to provide exceptional abrasion resistance and corrosion protection for pipelines handling abrasive slurries, corrosive chemicals, and wastewater. Compliant with standards like ASTM D2000 and DIN 22131, these pipes are ideal for mining, chemical processing, and industrial applications.

The Rubber Lining for Pipes is applied through vulcanization, bonding soft or hard rubber (e.g., natural rubber, neoprene, or butyl rubber) to the inner surface of the pipe using adhesives and heat curing. This creates a seamless, flexible barrier that withstands aggressive media. Available in diameters from 2” to 60” and lining thicknesses from 3 mm to 10 mm, these pipes support lengths up to 12 meters or customized configurations.

Abrasion-Resistant Pipes undergo rigorous testing, including adhesion, abrasion, and chemical resistance tests, ensuring compliance with industry standards. The rubber lining’s high elasticity and low surface friction enhance flow efficiency and reduce wear from abrasive materials like sand, gravel, or coal slurries. With a service life of 10–25 years, these pipes operate effectively in temperatures from -40°C to 100°C, depending on the rubber type.

Compared to HDPE linings or epoxy coatings, Rubber Lined Pipes offer superior abrasion resistance and flexibility, making them ideal for high-wear applications like slurry transport. They require minimal maintenance and can be relined, extending pipeline life cost-effectively. Proper surface preparation (e.g., abrasive blasting to Sa 2.5) and curing ensure strong adhesion and durability.

Rubber Lined Pipes address pipeline wear, corrosion, and fouling, providing reliable, cost-effective, and durable solutions for mining, chemical, and wastewater systems, ensuring long-term performance in harsh environments.

Rubber Lining Overview

Our rubber linings provide effective protection for steel and concrete components against chemical and mechanical attack.

Depending on the medium and temperature, we use materials based on natural rubber, halobutyl rubbers, chloroprene and styrene-butadiene rubbers.

Rubber linings offer:

Typically, our rubber linings are used at temperatures up to approx. 120°C. A unique feature is our KERABUTYL HT, which extends the application range of rubber linings up to 150°C.

lined piping

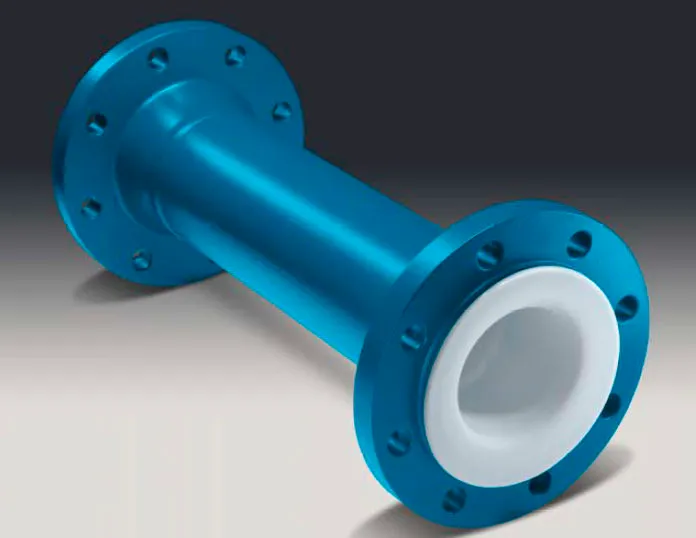

These are the metal surrounds of pipe and fittings, the fluoropolymer used to line them and the processing method (and thereby the type of fit between the metal and the lining).

The metal surround provides the mechanical strength for the system, the lining its corrosion performance.

Our plant carefully considers temperature, chemical composition and concentration of the materials being conveyed to determine the best compound for your rubber pipe.

The steel pipe is fabricated to required dimensions, ensuring strength and durability.

Thorough inspection of weld joints to detect defects before further processing.

Surface is blasted to remove impurities and create a rough texture for adhesion.

Adhesive layers are applied to ensure strong bonding between pipe and rubber lining.

Rubber tube is produced, stitched at seams, and prepared for insertion.

Rubber tube is inserted into pipe and flange faces are carefully applied.

The rubber lining is vulcanized under heat and pressure to ensure maximum strength.

Lining undergoes inspection and spark testing to confirm integrity and defect-free bonding.

Unlined surfaces are blasted and painted, followed by final inspection for quality assurance.

Pipe size is never a concern when working with Industrial Rubber.

An innovative application process makes it possible to rubber line pipe ranging from 3 inches in diameter up to the largest diameter manufactured.

Since most Rubber Lined Pipe applications are for transporting abrasive slurries, we test our materials for abrasion resistance to ensure we are providing you with the best product suited to your application.

We install rubber linings in pipe as small as 1½” dia. and as large as 144″ dia. We vulcanize (cure) the lining installed in pipe up to 88″ diameter (flanged) in our autoclaves. Curing in an autoclave produces superior adhesion properties over other processes (i.e. atmospheric and internal steam). Autoclave curing also maximizes the lining life in the pipe versus other methods.

We can fabricate and rubber line your pipe with a minimum lead-time. All Rubber Lined Pipe orders receive the same attention, whether it’s a large order, or a single piece.

It is vital to recognize the important differences between rubber-lined pipes and PTFE-lined pipes. PTFE-lined pipes are often used in situations where heat is extreme, whereas rubber-lined pipes are typically used at less heat temperatures.

PTFE-lined pipes are made of stainless steel and are able to withstand very high temperatures. A leak or explosion could result in a fire or explosion in the chemical industry or other sectors. These pipes have an extremely low coefficient of friction and low thermal expansion which means they can stand against all changes in environment temperature without warping or cracking or containing any damages. These pipes are very light in weight also resistant to corrosion and chemicals which can damage the pipes. These PTFE lined pipes install in tight spaces like under or above floors as they are very light in weight.

Rubber-lined pipes are typically made of PVC plastic, but can also be made from other materials such as glass fibers or metal tubes lined with rubber. These pipes have a higher coefficient of friction than metal ones do; this means that they will not slip against each other as easily when pushed together (like when you’re trying to push two pieces of paper together).

Explore Rubber Lined Pipes with targeted long-tail keywords for specifications, applications, and lining solutions.

Note: Rubber Lined Pipes meet ASTM and DIN standards, ensuring reliable performance. Contact suppliers for detailed specifications.

| Component | Natural Rubber (%) | Neoprene (%) | Butyl Rubber (%) | Function |

|---|---|---|---|---|

| Base Polymer | 60–70 | 50–65 | 55–70 | Provides elasticity and strength |

| Carbon Black/Fillers | 20–30 | 25–35 | 20–30 | Enhances abrasion resistance |

| Vulcanizing Agents (Sulfur) | 2–5 | 2–5 | 1–3 | Ensures curing and durability |

| Additives (Antioxidants, Plasticizers) | 5–10 | 5–10 | 5–10 | Improves chemical and UV resistance |

The Rubber Lined Pipe uses natural or synthetic rubber linings tailored for abrasion and corrosion resistance in industrial applications.

| Property | Natural Rubber | Neoprene | Butyl Rubber | Test Standard |

|---|---|---|---|---|

| Tensile Strength | 15–25 MPa | 10–20 MPa | 8–15 MPa | ASTM D412 |

| Elongation at Break | 400–600% | 300–500% | 300–400% | ASTM D412 |

| Hardness (Shore A) | 40–60 | 50–70 | 50–65 | ASTM D2240 |

| Abrasion Resistance | Excellent | Good | Moderate | ASTM D5963 |

| Chemical Resistance | Moderate (acids) | Good (oils, chemicals) | Excellent (gases, acids) | ASTM D471 |

| Temperature Range | -40°C to 70°C | -30°C to 100°C | -40°C to 80°C | N/A |

These properties ensure Rubber Lined Pipes deliver superior abrasion resistance and flexibility for demanding industrial applications.

| Feature | Rubber Lining | HDPE Lining | FBE Coating |

|---|---|---|---|

| Material | Natural/synthetic rubber | High-density polyethylene | Epoxy powder |

| Abrasion Resistance | Superior, ideal for slurries | Excellent | Good |

| Corrosion Resistance | Good, varies by rubber type | Superior, chemically inert | Excellent |

| Application Method | Vulcanization/bonding | Trenchless insertion | Electrostatic spray |

| Temperature Range | -40°C to 100°C | -40°C to 80°C | -30°C to 120°C |

| Lifespan | 10–25 years | 50–100 years | 20–30 years |

Rubber Lined Pipes excel in abrasion resistance and flexibility compared to HDPE linings and epoxy coatings, ideal for slurry and chemical pipelines.

The Rubber Lined Pipe available in various lengths.

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...

Fbe coated pipes provide excellent corrosion resis...