Polytetrafluoroethylene Lining For Superior Chemical Protection

Ptfe pipe lining offers unmatched chemical and corrosion resistance for chemical, pharmaceutical, and high-purity pipelines, ensuring durability and safety.

Polytetrafluoroethylene Lining For Superior Chemical Protection

Ptfe pipe lining offers unmatched chemical and corrosion resistance for chemical, pharmaceutical, and high-purity pipelines, ensuring durability and safety.

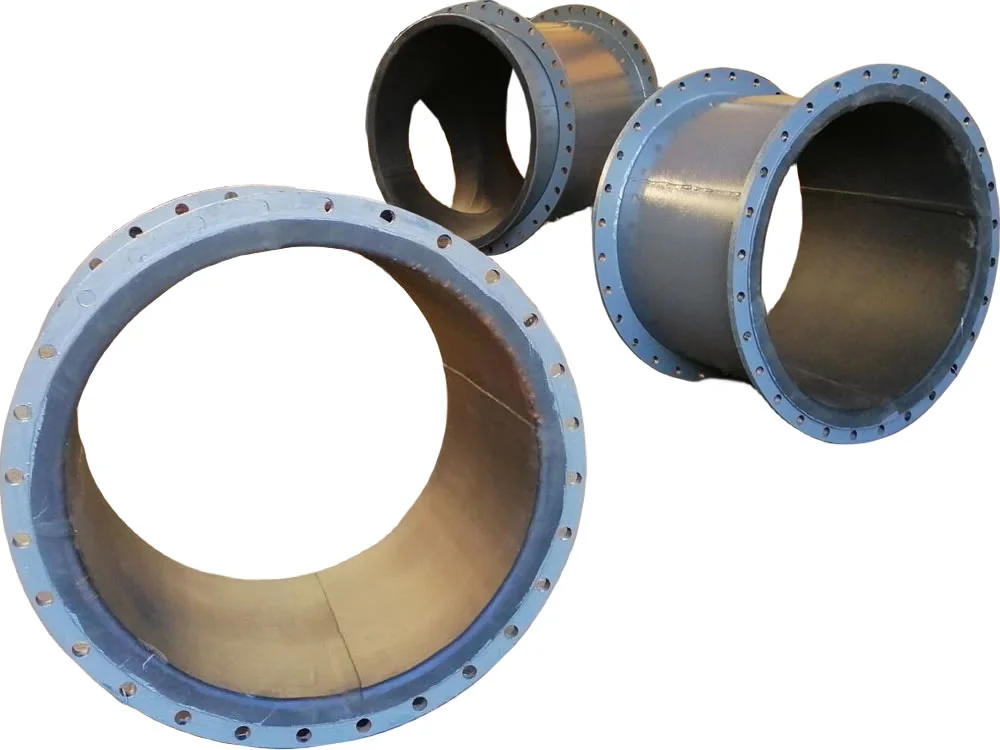

PTFE Pipe Lining utilizes Polytetrafluoroethylene (PTFE), a fluoropolymer known for its exceptional chemical resistance and corrosion resistance, to protect steel or alloy pipelines in harsh industrial environments. Compliant with ASTM F423 and ASTM D1457, these linings are ideal for chemical processing, pharmaceuticals, and high-purity applications requiring non-reactive surfaces.

The Polytetrafluoroethylene Lining is applied through processes like isostatic molding, paste extrusion, or loose lining, where PTFE sheets or tubes are bonded or mechanically fixed inside the pipe. This creates a seamless, non-stick barrier resistant to nearly all chemicals, including acids, alkalis, and solvents. Available in diameters from 1/2” to 24” and lining thicknesses from 2 mm to 6 mm, these pipes support lengths up to 6 meters or customized configurations.

Chemical Resistant Pipes undergo stringent testing, including spark testing, adhesion, and chemical immersion tests, ensuring compliance with industry standards. The PTFE lining’s low friction coefficient (0.05–0.10) enhances flow efficiency, while its temperature resistance (-200°C to 260°C) supports extreme conditions. With a service life of 10–20 years, these linings are perfect for aggressive media and high-purity systems.

Compared to rubber or HDPE linings, PTFE Pipe Lining offers unparalleled chemical inertness and temperature tolerance, though at a higher cost. It requires careful handling to prevent mechanical damage and is often paired with flanged or flared ends for secure installation. Maintenance is minimal, with periodic inspections to ensure lining integrity.

PTFE Pipe Lining addresses corrosion, chemical attack, and contamination in pipelines, providing reliable, high-performance solutions for chemical, pharmaceutical, and food processing industries, ensuring safety and longevity in demanding applications.

PTFE pipe lined elbow

PTFE lined elbows are manufactured with angles of 90°, 60°, 45° or 30°. Other angles are available on request.

PEFE pipe lined tee

The PTFE lined equal tees and reducing tees have very low permeation rates, substantial wall thicknesses and long service lives.

Unveiling our innovative PTFE pipe lining solutions, designed to revolutionize pipe protection. With superior durability and unmatched chemical resistance, our PTFE lined pipes redefine industry standards.

Provides excellent resistance to corrosive fluids, ensuring long-term durability in aggressive environments.

Withstands elevated temperatures, ideal for demanding industrial applications.

Inert and compatible with acids, bases, solvents, and corrosive substances.

Ensures smooth flow and reduces pressure drop within the pipeline.

Produced via paste extrusion, isostatic molding, or injection molding to suit different pipe dimensions.

Used in chemical processing, pharmaceuticals, food & beverage, water treatment, and semiconductor industries.

Available in various sizes and pressure ratings for diverse applications.

Typically installed with flanges for easy connection and maintenance.

Tested for porosity and hydrostatic integrity to guarantee performance and safety.

PTFE pipes and rollings – suitable for manufacturing of bushes, compressor rings, etc made from polytetrafluorethylene PTFE – stable and resistible material, chemically inert, non-flammable with high dielectric strength.

PTFE tubes

It is vital to recognize the important differences between rubber-lined pipes and PTFE-lined pipes. PTFE-lined pipes are often used in situations where heat is extreme, whereas rubber-lined pipes are typically used at less heat temperatures.

PTFE-lined pipes are made of stainless steel and are able to withstand very high temperatures. A leak or explosion could result in a fire or explosion in the chemical industry or other sectors. These pipes have an extremely low coefficient of friction and low thermal expansion which means they can stand against all changes in environment temperature without warping or cracking or containing any damages. These pipes are very light in weight also resistant to corrosion and chemicals which can damage the pipes. These PTFE lined pipes install in tight spaces like under or above floors as they are very light in weight.

Rubber-lined pipes are typically made of PVC plastic, but can also be made from other materials such as glass fibers or metal tubes lined with rubber. These pipes have a higher coefficient of friction than metal ones do; this means that they will not slip against each other as easily when pushed together (like when you’re trying to push two pieces of paper together).

Explore PTFE Pipe Lining with targeted long-tail keywords for specifications, applications, and chemical resistance solutions.

Note: PTFE Pipe Linings meet ASTM and FDA standards, ensuring reliable performance. Contact suppliers for detailed specifications.

PTFE Pipe Lining typically refers to a type of polyethylene-coated steel pipe used in water distribution, drainage, and gas supply systems.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...