Fusion Bonded Epoxy Coating For Pipeline Durability

Fbe coated pipes provide excellent corrosion resistance for oil, gas, water, and chemical pipelines, ensuring durability and cost-effective performance.

Fusion Bonded Epoxy Coating For Pipeline Durability

Fbe coated pipes provide excellent corrosion resistance for oil, gas, water, and chemical pipelines, ensuring durability and cost-effective performance.

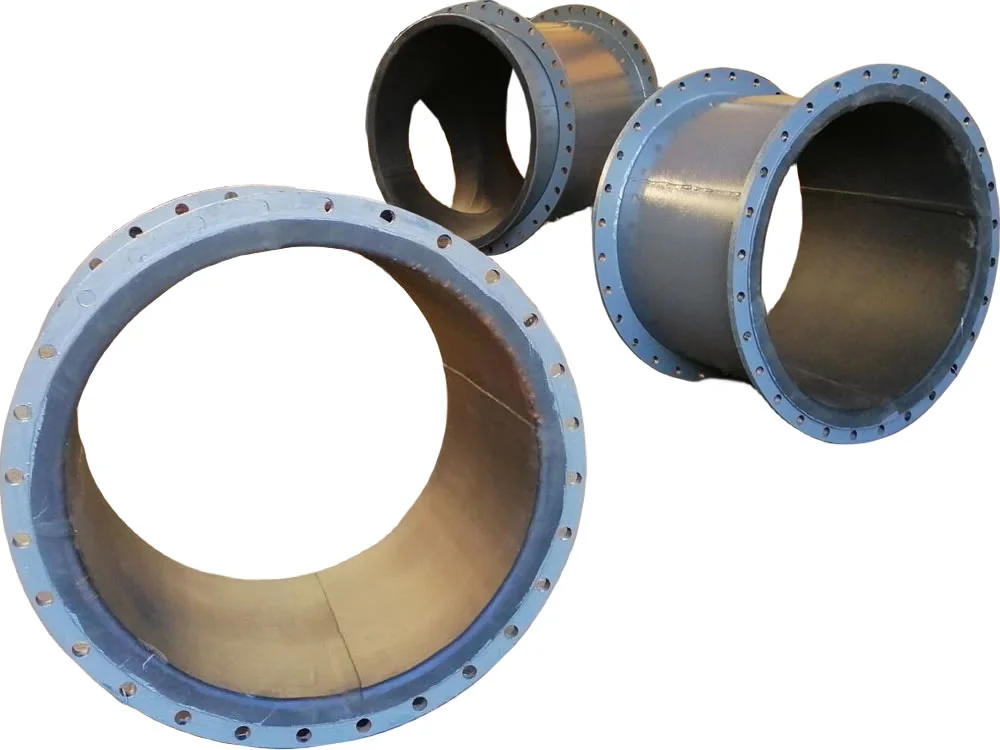

FBE Coated Pipe features a Fusion Bonded Epoxy coating applied to steel pipes, offering superior corrosion resistance and durability for oil, gas, water, and chemical pipelines. Compliant with standards like NACE SP0394, ISO 21809, and CSA Z245.20, these pipes are engineered for harsh environments and long-term performance.

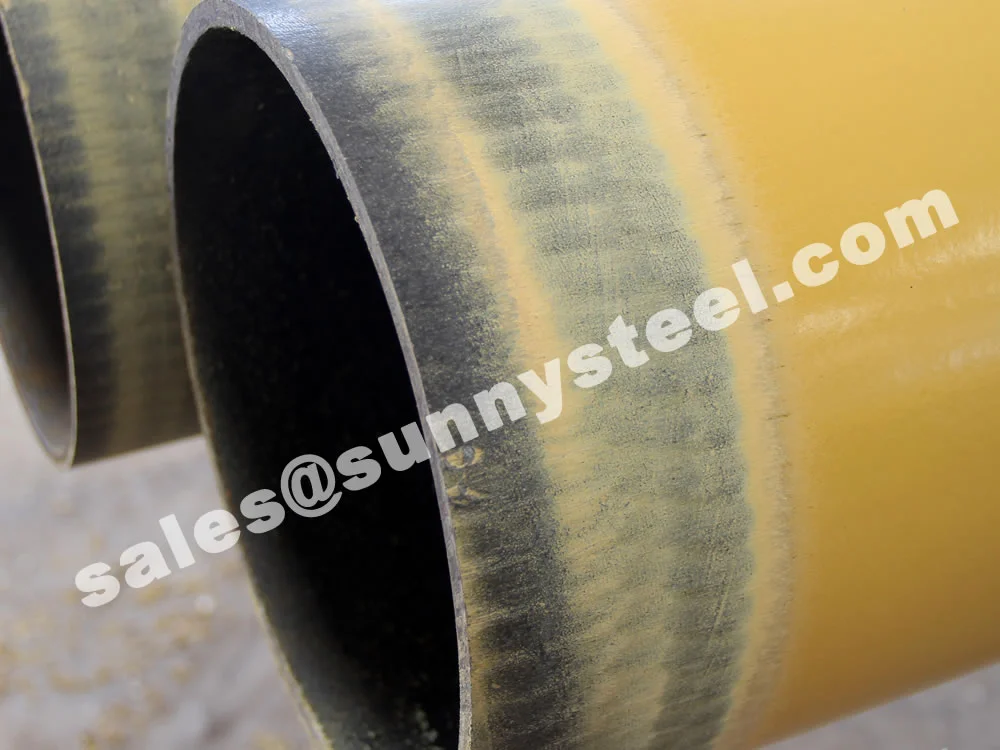

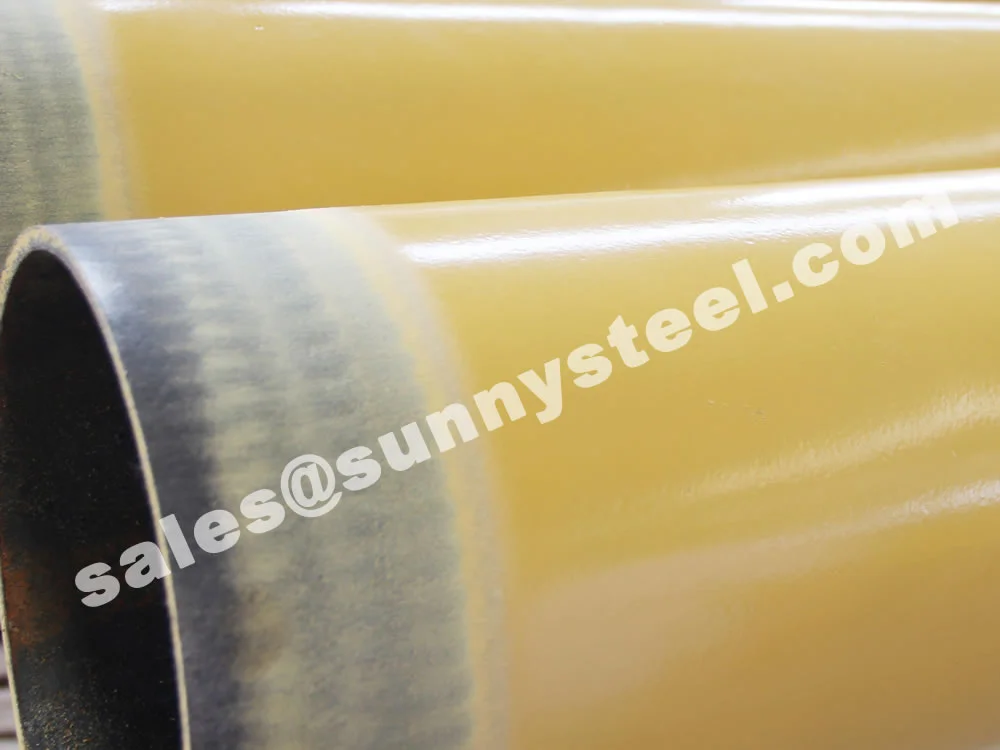

The Fusion Bonded Epoxy Coating is applied by electrostatically spraying epoxy powder onto preheated pipes (180–250°C), forming a uniform, tightly bonded layer upon curing. This coating, typically 250–500 microns thick, protects against corrosion, chemicals, and moderate abrasion. Available in diameters from 2” to 48” and lengths up to 12 meters, FBE Coated Pipes suit both onshore and offshore applications.

Corrosion Resistant Pipes undergo rigorous testing, including holiday detection, adhesion, and cathodic disbondment tests, ensuring compliance with industry standards. The smooth coating surface (Ra ~0.5–2.5 µm) enhances flow efficiency, reducing friction and energy costs. FBE coatings withstand temperatures up to 120°C, making them suitable for oilfields, water distribution, and chemical plants.

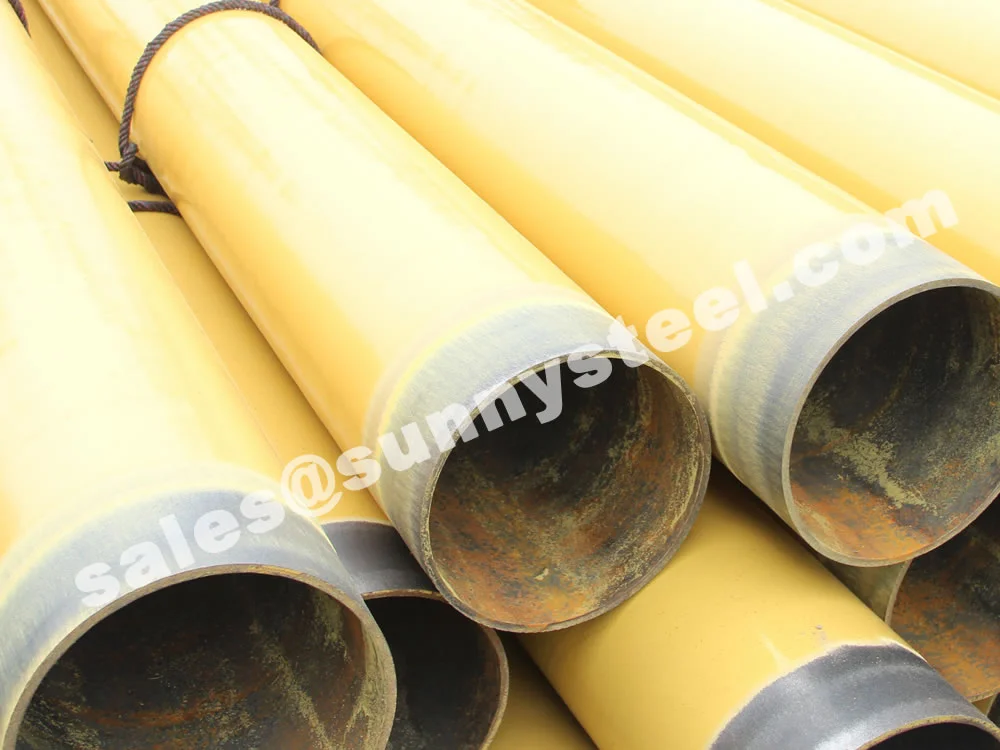

Compared to liquid epoxy or HDPE linings, FBE Coated Pipes offer excellent chemical resistance, ease of application, and cost-effectiveness, particularly for large-diameter pipelines. Surface preparation via abrasive blasting (to Sa 2.5) ensures optimal adhesion, while proper curing prevents defects like pinholes. These pipes require minimal maintenance, extending service life up to 20–30 years.

FBE Coated Pipes address pipeline corrosion, chemical degradation, and operational inefficiencies, providing reliable, cost-effective, and environmentally friendly solutions for industrial piping systems in demanding conditions.

Once the FBE is coated on the pipe surface, the FBE film provides an extremely hard surface with great adhesion to the surface of the pipe.

The steel pipes are treated by shot blasting and intermediate frequency preheating before painting, and then the epoxy powder coating is sprayed on the surface of the heated pipe products by electrostatic spraying method, which melts and bonds on the surface of the steel pipe and solidifies to form a coating. FBE coating is usually a one - step film forming structure.

Loading FBE coating pipes

The coating provides excellent resistance to acidic and alkaline environments and protection against mechanical damage and abrasion.

Excellent adhesion to steel ensures superior long-term corrosion resistance. Service life can exceed 100 years, even at moderate operating temperatures.

Superior adhesion offers excellent cathodic disbondment resistance, minimizing the overall cost of cathodic protection during pipeline operation.

Customized FBE coatings are available for high-temperature service, high-strength steels, and specialized applications.

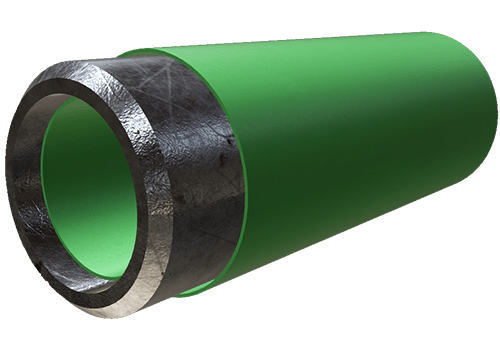

Dual-layer FBE coatings provide robust mechanical strength, protecting against damage during handling, transit, installation, and operation.

Offers excellent chemical resistance in diverse soil environments. Prevents bacterial growth, scaling, and blockage risks commonly associated with cement-lined pipes.

Provides 15–20% greater water volume compared to cement-lined pipes of the same diameter, ensuring higher efficiency and flow capacity.

EXTERNAL COATING AND INERNAL LINING

FBE coating gets applied to both the exterior and interior of the pipe and is a highly effective method of protecting the pipe from corrosion.

3PE coated pipes are widely used in industries like oil and gas, water supply, and chemical pipelines due to their exceptional durability and performance.

The 3PE coating provides excellent protection against corrosion, preventing rust and extending the lifespan of steel pipes, even in aggressive environments such as underground or underwater installations.

3PE pipes withstand mechanical stress, abrasion, and impact. The coating provides extra protection during transportation, installation, and operation, making them ideal for harsh conditions.

The polyethylene coating can handle temperatures from -40°C to +80°C, making 3PE pipes suitable for both low and high-temperature environments.

The 3PE coating resists acids, alkalis, and other aggressive substances, making these pipes ideal for chemical and industrial applications.

3PE pipes are environmentally friendly and meet safety standards, preventing leaks and ensuring contaminants do not pollute the surrounding environment.

These pipes are easy to install and require minimal maintenance due to their durable, long-lasting coating, reducing maintenance costs over time.

While offering superior protection, 3PE pipes are relatively affordable, providing long-term savings by reducing the need for frequent repairs and replacements.

3PE pipes are versatile and can be used in water pipelines, oil and gas transportation, and chemical industry systems.

The polyethylene coating provides excellent thermal insulation, preventing heat loss during fluid transport and ensuring energy efficiency in high-temperature applications.

Pipelines are a vital part of our infrastructure, so it is essential that they are well - protected to prevent damage and leaks. One type of coating used on pipelines is fusion bonded epoxy (FBE).

Recently, two segments of pipeline coated with FBE more than 30 years ago underwent exploratory inspection as part of the risk assessment process. The results from laboratory tests and field inspections were unequivocal: the coating was properly applied and is still in good condition. This is positive news, as it shows that FBE can provide long - term protection for pipeline segments. The inspection also provided additional validation of the ability of the FBE coating to work in unity with cathodic protection to provide superior pipeline protection. This information is valuable not only for pipeline operators but also for those involved in specifying pipeline coatings for new construction projects.

The pipeline industry has long relied on FBE coatings to protect their pipelines from corrosion and degradation, and the latest tests prove that they are still effective. The FBE manufacturer has revised their coating formulation several times to improve corrosion protection and mechanical properties, but the older generation of FBE - coated pipe installed more than 30 years ago is still performing well. There are no indications of significant coating degradation and it is clear that the FBE system will continue to perform for many years. This is clear evidence of the durability and effectiveness of FBE coatings. Pipeline operators can be confident in this tried - and - true coating technology for many years to come.

Pipeline integrity management programs are usually focused on more recent coatings, but excavations and inspections provide valuable insights into the long - term performance of early generation FBE coatings. These evaluations validate current formulations and give greater confidence in their efficacy.

Many changes and developments have taken place in FBE coating technology since the 1970s, so these older coatings provide valuable data points. In addition, the inspection of long - standing coated pipe can yield invaluable insights into the degradation of these early generation coatings.

Explore FBE Coated Pipes with targeted long-tail keywords for specifications, applications, and corrosion protection solutions.

Note: FBE Coated Pipes meet NACE, ISO, and CSA standards, ensuring reliable performance. Contact suppliers for detailed specifications.

The FBE Coated Pipe uses a high-quality epoxy-based coating to ensure robust corrosion protection and chemical resistance in industrial applications.

| Component | Content (%) | Function |

|---|---|---|

| Epoxy Resin | 60–80 | Provides adhesion and chemical resistance |

| Hardener/Curing Agent | 10–20 | Ensures curing and durability |

| Fillers (Silica, Talc) | 10–20 | Enhances mechanical strength |

| Pigments/Additives | 2–5 | Improves UV and thermal stability |

| Property | Value | Test Standard |

|---|---|---|

| Adhesion Strength | ≥30 MPa | ASTM D4541 |

| Hardness (Shore D) | 80–90 | ASTM D2240 |

| Impact Resistance | ≥1.5 J | ASTM G14 |

| Chemical Resistance | Excellent (pH 2–12) | ASTM D543 |

| Temperature Range | -30°C to 120°C | N/A |

| Surface Roughness (Ra) | 0.5–2.5 µm | ISO 4287 |

| Cathodic Disbondment | ≤8 mm radius | ASTM G95 |

These properties ensure FBE Coated Pipes provide reliable corrosion protection and flow efficiency in demanding industrial environments.

| Feature | FBE Coating | Liquid Epoxy Coating | PTFE Lining | HDPE Lining |

|---|---|---|---|---|

| Material | Epoxy powder | Liquid epoxy | Polytetrafluoroethylene | High-density polyethylene |

| Corrosion Resistance | Excellent | Good | Superior | Excellent |

| Abrasion Resistance | Good | Moderate | Moderate | Excellent |

| Application Method | Electrostatic spray | Spray/brush | Isostatic molding | Trenchless insertion |

| Temperature Range | -30°C to 120°C | -20°C to 80°C | -200°C to 260°C | -40°C to 80°C |

| Lifespan | 20–30 years | 15–25 years | 10–20 years | 50–100 years |

| Cost | Moderate | Low | High | Moderate |

FBE Coated Pipes offer superior chemical resistance and ease of application compared to liquid epoxy, with better cost-effectiveness than PTFE linings.

| Category | Details |

|---|---|

| Product | LSAW PIPE / SSAW PIPE |

| Standard | EN10210, EN10217, EN10219, ASTM A252 (Piling pipe), ASTM A572, ASTM A53, API5L |

| Grade | S235, S275, S355JRH, S355J0H, S355J2H, GR.1, GR.2, GR.3, x12, x20 |

| Size | 16 INCH - 64 INCH (406 - 1626MM) |

| Thickness | 6MM - 80MM |

| Length | 12 - 12.2M |

The Fusion Bonded Epoxy (FBE) Coated Pipes is needed for pipes that are exposed to harsh environments, like those that come into contact with salt water, chemicals, and other corrosive materials.

Rubber lined pipes offer superior abrasion and cor...

3pe pipes offer superior corrosion resistance for ...

Ipn 8710 coating consists of polyurethane resin an...

3pp pipes offer superior corrosion and temperature...

Pipe cement mortar lining provides durable corrosi...