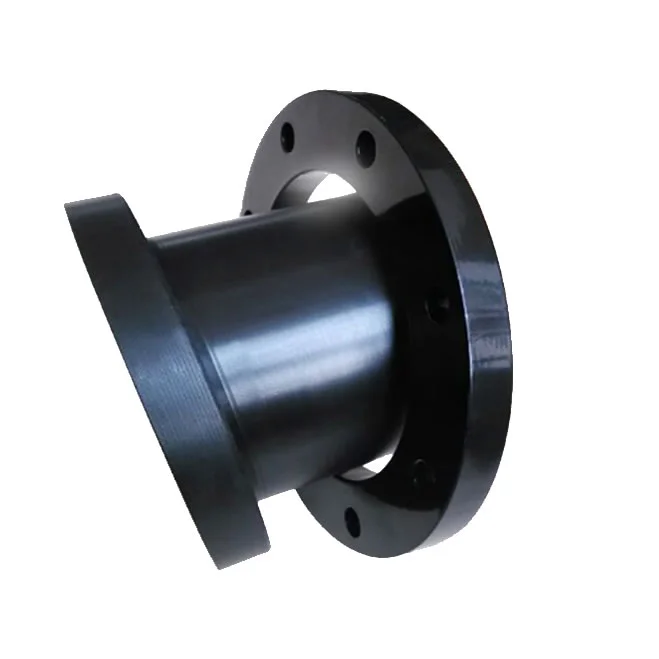

Lap Joint Flange is a two-part fitting combining a stub end and a loose backing flange, designed for easy alignment and disassembly in piping systems. Compliant with ASME B16.5 and DIN standards, it is made from carbon steel, stainless steel, and alloys for durability.

The Flexible Pipe Flange allows the flange to rotate, simplifying bolt hole alignment during installation, and is ideal for systems requiring frequent maintenance. Available in sizes from 1/2” to 48” with pressure ratings up to 1500 PSI, it pairs with a stub end for corrosion resistance.

Lap Joint Flange undergoes hydrostatic and dimensional testing to ensure reliability. Its design supports temperatures from -20°C to 400°C, depending on material, and is coated with galvanizing or FBE to enhance corrosion resistance, making it suitable for petrochemical applications.

Compared to weld neck flanges, Lap Joint Flange offers cost savings and flexibility, especially in corrosive environments, as the stub end takes the corrosion load. Proper installation with aligned bolts and gaskets ensures a tight seal. It boasts a service life of 20–35 years.

Lap Joint Flange addresses challenges like misalignment and corrosion in industrial piping, providing an adaptable, durable solution for petrochemical, water treatment, and power generation systems.

What is a lap-joint flange?

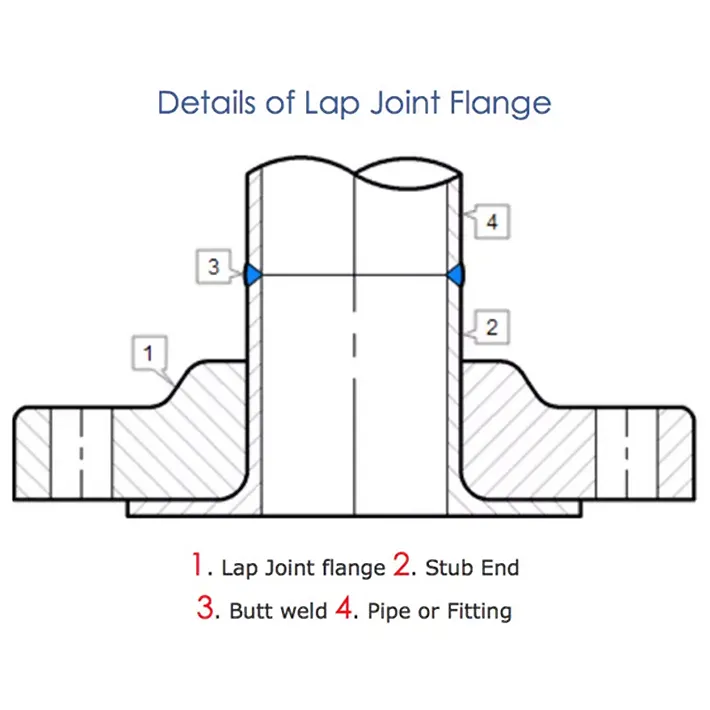

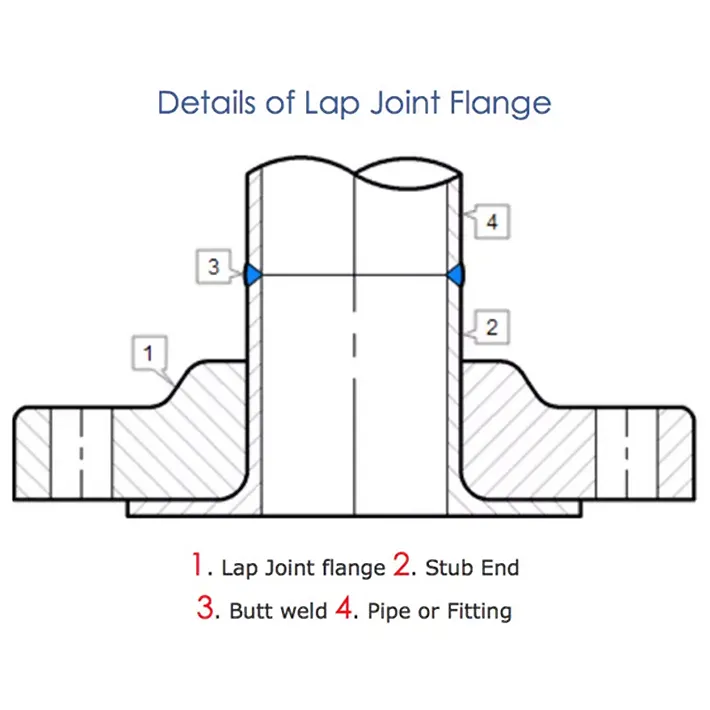

A lap-joint flange is a two-component assembly, with a stub end that has a lap-joint ring flange placed over it.

Lap Joint flanges are sometimes referred to by other names, including:

- Stub end flange

- Loose flange

- Backing flange

- Vanstone and Backing Ring

Lap joint flange is used with a lap joint stub end fitting. Lap joint flange is similar to a slip-on flange, but with two differences. The radius and the flat face, both allow the flange to secure against the stub end fitting. This is useful where alignment of bolt holes is difficult, such as with spools to be attached to flanged nozzles of vessels. A lap joint is used in low pressure applications and not suitable where high external of heavy loads are present.

These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel.

Lap joint flanges are usually used in low pressure applications and are not suitable when there are high loads on the flange pair. Some types of piping require the use of lap joint flanges. For example, metallic pipe that has been plastic lining may have lap joint flanges.

Using lap joint flanges might be an option for saving costs when the piping is made of exotic materials. By using a lap joint flange, the wetted materials would consist of the exotic materials and the flange would be carbon steel. Since the flange doesn’t ever come in contact with the process fluid, it would not be affected by the fluids.

Dimensions on the lap joint flange are similar to weld neck, slip on or socket weld flanges. The backing flange has the same number of bolt holes, size and thickness of a weld neck or slip on flange.

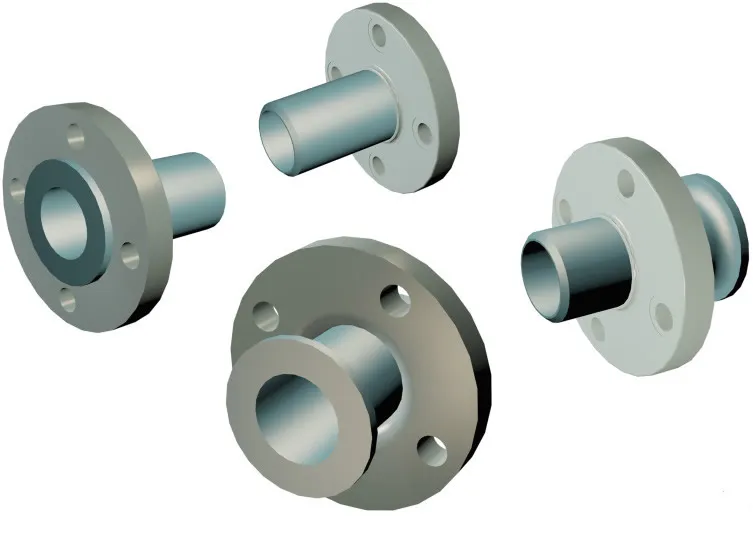

Lap joint flange (simplified as LTF flange) shape is similar to slip on flange, it has a curved radius at the bore, which can connect with a stub end fittings and slide over the pipe. In this form, the pipe is usually welded to this stub end so the lap joint flange can rotate freely around the stub end.

The advantage of this combination that it will be easy with alignment for the bolt hole, easy to install and uninstall, much more convenient to do examinations and maintenance.

The lap joint stub end is butt welded to the pipe, while the lap joint flange is slid onto the pipe before the final welding takes place. The flange has a raised flat portion called the lap, which allows it to overlap with the flanged portion of the stub end, creating a tight seal.

Lap joint flanges are known for their ease of installation and cost-effectiveness. They provide flexibility and can accommodate slight misalignment or movement between the pipe and the flange. However, they are not as strong as other types of flanges, such as welding neck or slip-on flanges.

It's important to note that lap joint flanges should not be used in applications with high temperatures or high pressures, as they may not provide the necessary strength and sealing capabilities. Consulting with a qualified engineer or referring to relevant standards and guidelines is recommended when selecting the appropriate flange type for a specific application.

Lap joint flange with stub end

Working Environment

Lap joint flange is typically used for low pressure application.

It is not suitable when the flange pair need to bear high loads. Some pipes required to use this type flange, like a metal pipe already lined with plastic may have to use lap joint flanges.

Design of Lap Joint Flange

A lap joint flange consists of two main components:

-

Flat Face Flange: The flat face flange is the main body of the lap joint flange. It has a flat surface with bolt holes to secure the flange to the mating flange or pipe.

-

Stub End: The stub end is a short piece of pipe with a lap joint configuration. It slides over the pipe end and allows the flange to rotate freely, providing flexibility during alignment.

The lap joint flange is typically used with a gasket to ensure a leak-proof joint between the flanges.

Lap joint flanges play a crucial role in various industries, offering a practical and cost-effective solution for pipe connections that require easy assembly and disassembly. Their design allows for flexibility during alignment, making them suitable for a wide range of applications in the petrochemical, oil and gas, water treatment, food and beverage, and chemical processing industries. When it comes to ensuring efficient and reliable pipe connections, lap joint flanges prove to be an essential component in modern piping systems.

Lap joint flange datasheets

The datasheets we have on this site are shown below. For simplicity sake, only datasheets that adhere to B16.5 are shown. ASME B16.5 covers flange dimensions from ½” to 24”. For sizes larger than this (ASME B16.47 Series A & B), please visit our flange datasheets page.

ANSI Class Specifications for Flat Face Lap Joint Flanges

| Class |

Flat Face |

| ANSI 150 |

Lap Joint, ANSI Class 150 (in) |

| ANSI 300 |

Lap Joint, ANSI Class 300 (in) |

| ANSI 400 |

Lap Joint, ANSI Class 400 (in) |

| ANSI 600 |

Lap Joint, ANSI Class 600 (in) |

| ANSI 900 |

Lap Joint, ANSI Class 900 (in) |

| ANSI 1500 |

Lap Joint, ANSI Class 1500 (in) |

| ANSI 2500 |

Lap Joint, ANSI Class 2500 (in) |