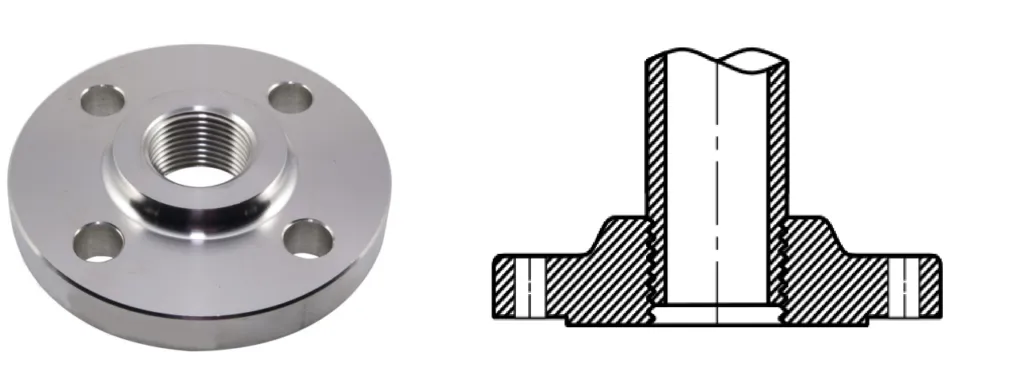

Threaded Flange

Easy And No-weld Piping Solution

Threaded flanges offer easy, no-weld piping connections with corrosion resistance, ideal for water, food, and low-pressure systems.

Threaded Flange

Easy And No-weld Piping Solution

Threaded flanges offer easy, no-weld piping connections with corrosion resistance, ideal for water, food, and low-pressure systems.