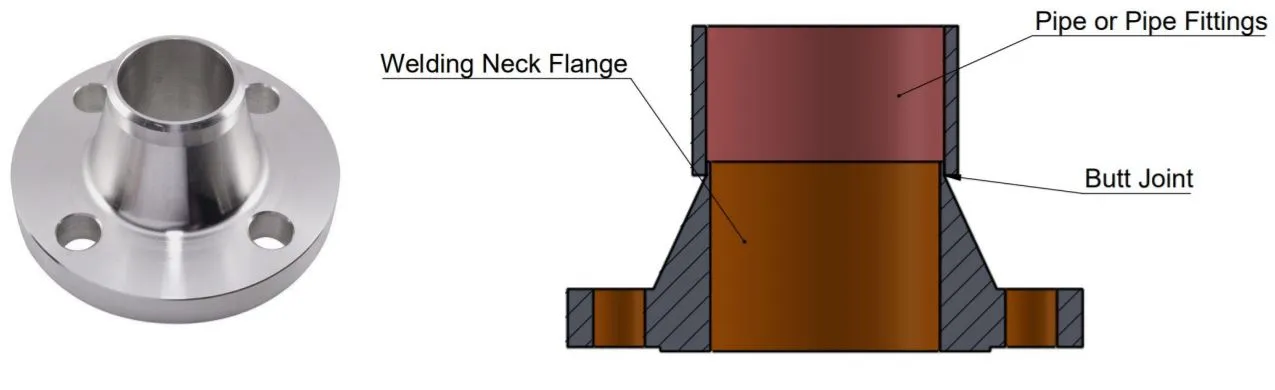

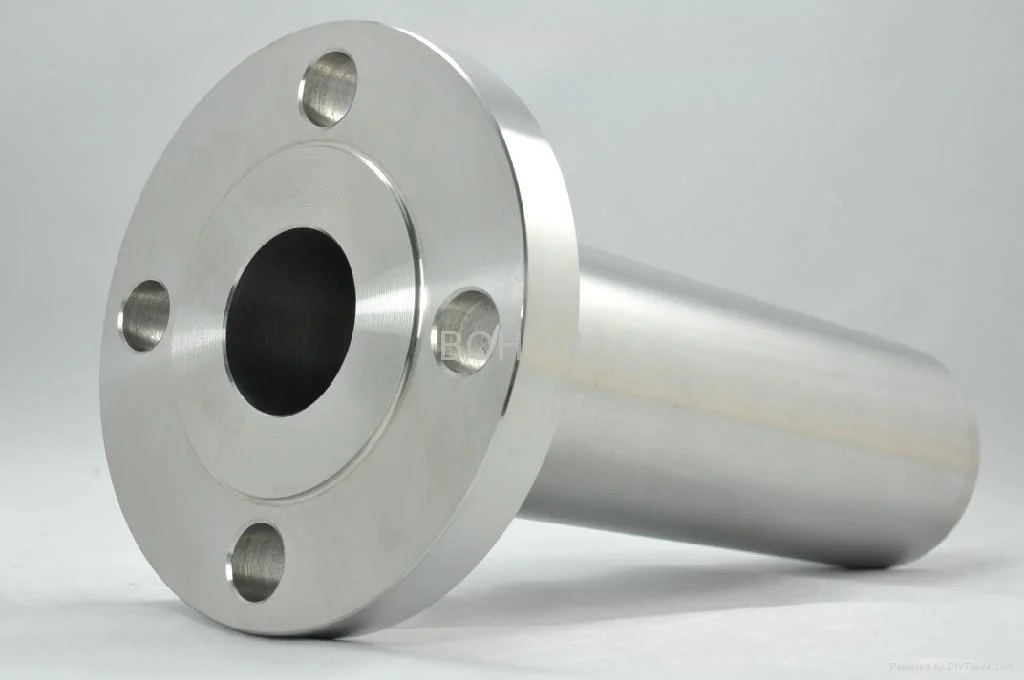

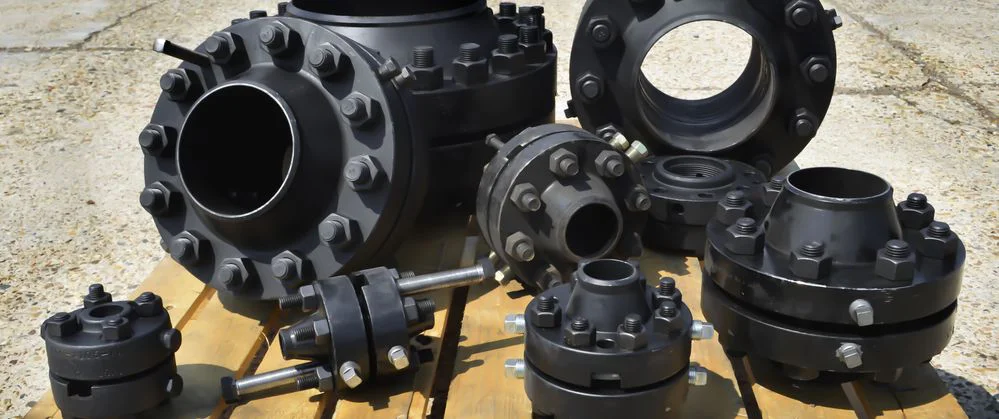

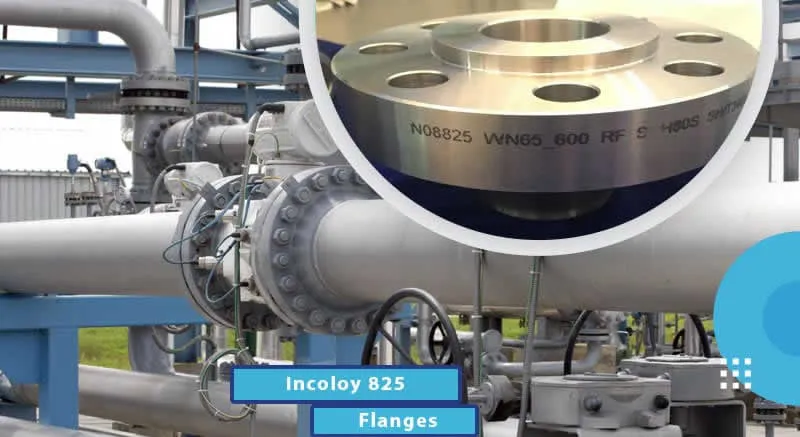

Welding Neck Flange

High-strength And High-pressure Piping Solution

Welding neck flanges provide high-strength, high-pressure piping connections with excellent corrosion resistance, ideal for oil, gas, and power systems.

Welding Neck Flange

High-strength And High-pressure Piping Solution

Welding neck flanges provide high-strength, high-pressure piping connections with excellent corrosion resistance, ideal for oil, gas, and power systems.