What Is A Carbon Steel Flange?

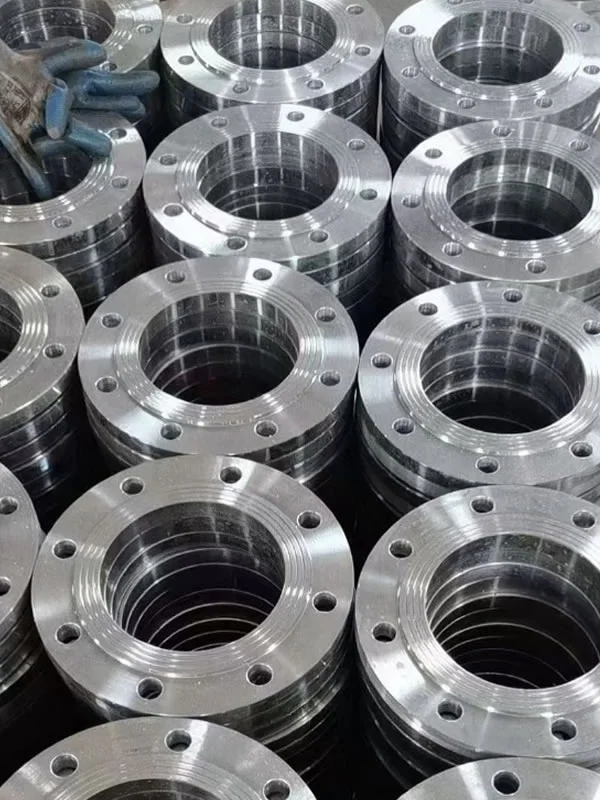

Carbon steel flange, that is, the flange plate or the end flange connection piece whose body is made of carbon steel. The flanges containing carbon steel are called carbon steel flanges. Common materials are cast carbon steel grades WCB, forgings A105, or Q235B, A3, 10#, #20 steel, 16 manganese, 45 steel, Q345B, etc.

Usually in order to prevent rusty flange surface with electroplating layer (yellow zinc, white zinc, etc.), or brush anti-rust oil and spray anti-rust paint treatment.

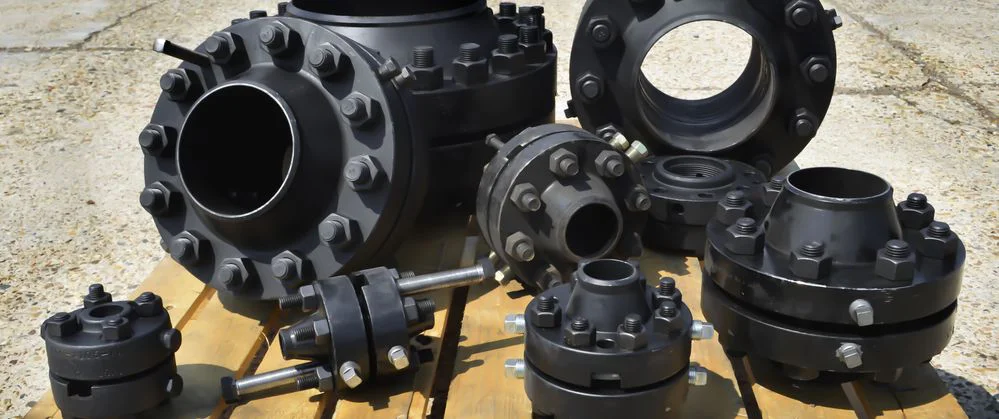

Carbon Steel Flanges are engineered from durable carbon steel, offering a cost-effective option for industrial piping. Compliant with ASME B16.5, they suit moderate-pressure systems. As of August 22, 2025, 01:36 AM PDT, they remain a popular choice.

These Cost-Effective Flanges are available in sizes from 1/2” to 48”, with pressure ratings up to 2500 PSI and temperature tolerance up to 400°C. Their robust construction makes them ideal for general industrial use.

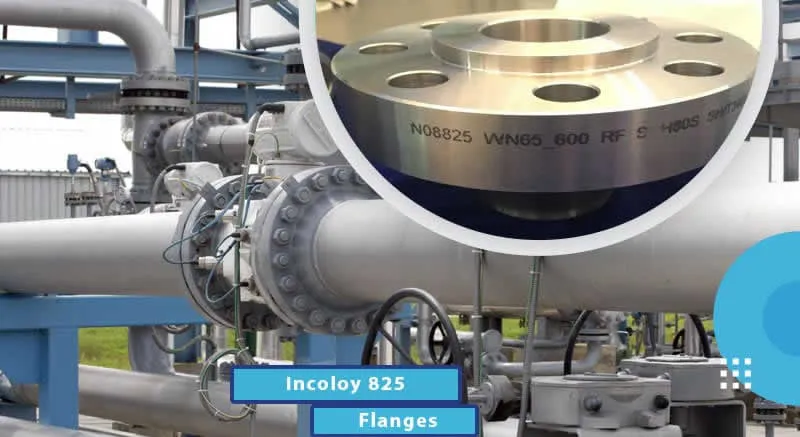

Carbon Steel Flanges undergo tensile, hardness, and hydrostatic testing for quality assurance. Coatings like galvanizing or FBE enhance corrosion resistance, making them suitable for oil and gas and water treatment as of August 2025.

Compared to stainless steel, Carbon Steel Flanges are more affordable but require protective coatings for corrosive environments, with a service life of 15–30 years with proper maintenance.

Carbon Steel Flanges address challenges like cost and moderate-pressure needs in industrial piping, providing a reliable solution as of August 22, 2025.

Modern carbon is a common steel with carbon content up to 2.1% by weight and primarily alloyed with iron. The term “carbon steel” may also be used to call out steel which does not have a large amount of chromium or nickel. The carbon content can vary for A105 with a maximum allowable of 0.35 as a percentage composition. As the carbon content increases, the steel hardens and increases in strength through heat treatment processes. Many common treatment techniques in the industry are quenching, tempering, and normalizing. As carbon steel is treated, it become less ductile and brittle. This makes it slightly more difficult to shape and weld, however the trade off in field service is often considered worth the extra effort to form the necessary weld seals.

For trace elements, no alloy element (minimum content) is required, specifically in reference to molybdenum, nickel, chromium, titanium, and vanadium.