Alloy Steel Flanges are designed from alloy steel, delivering high strength and temperature

resistance for industrial piping. Compliant with ASME B16.5, they excel in extreme conditions. As of August

22, 2025, 02:39 AM PDT, they are industry leaders.

These Temperature-Resistant Flanges range from 1/2” to 48” in size, with pressure ratings

up to 2500 PSI and temperature tolerance up to 550°C. They are ideal for power generation and petrochemical

applications.

Alloy Steel Flanges undergo tensile, hardness, and creep resistance testing for quality.

Coatings like 3LPE or galvanizing enhance durability, making them suitable for high-temperature and

corrosive environments as of August 2025.

Compared to carbon steel, Alloy Steel Flanges offer superior heat resistance and strength,

with a service life of 25–50 years with proper maintenance, balancing cost and performance.

Alloy Steel Flanges address challenges like high-temperature wear and corrosion in

industrial piping, providing a durable solution as of August 22, 2025.

ASTM A182 Low Alloy Steel flanges Chart And Weight

| Standard |

Class / Table |

Diameter (mm) |

Bolt Circle Diameter (mm) |

Number of Bolts |

Bolt Size |

Diameter of Bolt Hole (mm) |

| AS4087 Flanges |

PN14 Flanges |

95 |

67 |

4 |

M12 |

14 |

| AS 2129 Flange |

Table C Flanges |

95 |

67 |

4 |

13 |

14 |

| Table D Flanges |

95 |

67 |

4 |

13 |

14 |

| Table E Flanges |

95 |

67 |

4 |

13 |

14 |

| Table F Flanges |

95 |

67 |

4 |

13 |

14 |

| Table H Flanges |

114 |

83 |

4 |

16 |

17 |

| Table J Flanges |

114 |

83 |

4 |

16 |

17 |

| ANSI B16.5 Flanges |

ANSI 150 Flanges |

89 |

60 |

4 |

13 |

16 |

| ANSI 300 Flanges |

95 |

67 |

4 |

13 |

16 |

| ANSI 600 Flanges |

95 |

67 |

4 |

13 |

16 |

| ANSI 900 Flanges |

121 |

83 |

4 |

19 |

22 |

| ANSI 1500 Flanges |

121 |

83 |

4 |

19 |

22 |

| ISO 7005 (DIN) Flange |

PN6 Flange |

80 |

55 |

4 |

M10 |

11 |

| PN10 Flange |

95 |

65 |

4 |

M12 |

14 |

| PN16 Flange |

95 |

65 |

4 |

M12 |

14 |

| PN20 Flange |

90 |

60.5 |

4 |

M14 |

16 |

| PN25 Flange |

95 |

65 |

4 |

M12 |

14 |

| PN40 Flanges |

95 |

65 |

4 |

M12 |

14 |

Chemical Composition of Alloy Steel Grades (Weight Percentage)

| Grade |

C

(Carbon) |

Mn

(Manganese) |

Si

(Silicon) |

P

(Phosphorus) |

S

(Sulfur) |

Cr

(Chromium) |

Mo

(Molybdenum) |

| F1 |

0.15 max |

0.3-0.6 |

0.5 |

0.03 |

0.03 |

4-6 |

0.44-0.65 |

| F5 |

0.15 max |

0.3-0.6 |

0.5-1.0 |

0.03 |

0.03 |

4-6 |

0.44-0.65 |

| F9 |

0.15 max |

0.3-0.6 |

0.5-1.0 |

0.03 |

0.03 |

8-10 |

0.9-1.1 |

| F11 |

0.05-0.15 |

0.3-0.6 |

0.5-1.0 |

0.03 |

0.03 |

1.0-1.5 |

0.44-0.65 |

| F12 |

0.15 max |

0.3-0.6 |

0.5 |

0.03 |

0.03 |

4-6 |

0.44-0.65 |

| F22 |

0.15 max |

0.3-0.6 |

0.5 |

0.03 |

0.03 |

4-6 |

0.44-0.65 |

| F91 |

0.15 max |

0.3-0.6 |

0.5-1.0 |

0.03 |

0.03 |

8-10 |

0.9-1.1 |

Mechanical Properties of ANSI B16.5 Alloy Steel Flange

| Grade |

Tensile Strength

(MPa) |

Yield Strength

(0.2% Offset, MPa) |

Elongation |

| F1 |

275 |

485 |

20 % |

| F5 |

275 |

485 |

20 % |

| F9 |

380 |

585 |

20 % |

| F11 |

205 |

415 |

20 % |

| F12 |

275 |

485 |

20 % |

| F22 |

205 |

415 |

20 % |

| F91 |

380 |

585 |

20 % |

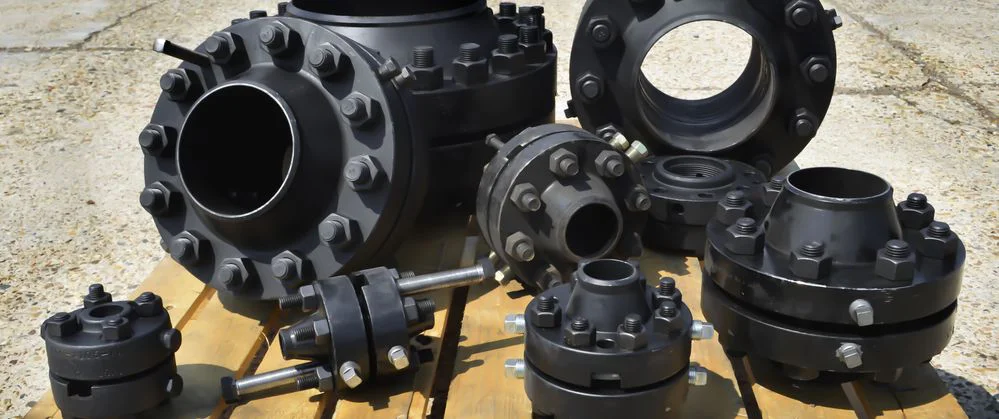

The ANSI B16.5 Alloy Steel Slip On Flange can be slid on any pipe and welded in exact positions. They are

the most popular and cost-effective flanges in the market. The High Alloy Steel Slip on Flange is made

up of high qualities of alloyed material. These flanges contain at least 12% of chromium and are known

for their hardenability. Low Alloy Steel Weld Neck Flange is designed with good mechanical properties.

These flanges have a protruding hub, which provides support to pipes in high-pressure applications. The

4130 Chromoly Threaded Flange is used as companion flanges in piping systems. Our experienced workers

make use of the latest technology and best raw materials whilst producing the ASME SA 182 AS Pipe Flange

and our other products.

The Chromoly 4130 Reducing Flange is used to combine pipes of different shapes and sizes. They are designed with a bore having a specified diameter. Alloy Steel Socket Weld Flanges are used in higher-pressure systems having small pipes. They are fitted after applying a fillet weld. The Chrome AS Blind Flange is designed with a boring center. They are used in sealing the nozzles or openings in piping systems. They can be welded permanently or bolted as per requirement. The Alloy Steel Blind Flanges along with, our other products can be easily customized as per your needs in different shapes and sizes. Contact us to know more.