High-yield Piping Solutions

Astm a694 flanges offer high-yield strength for high-pressure piping, ideal for oil and gas as of august 2025.

High-yield Piping Solutions

Astm a694 flanges offer high-yield strength for high-pressure piping, ideal for oil and gas as of august 2025. explore grades f42 to f70.

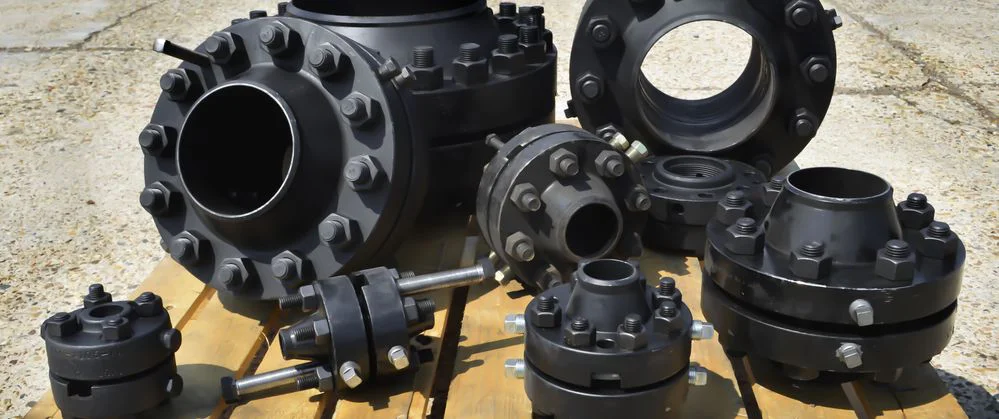

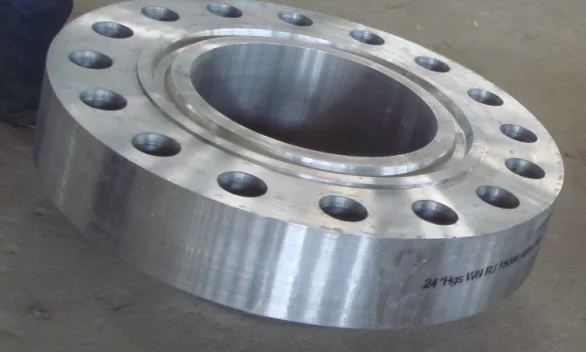

ASTM A694 Flanges are forged from high-yield carbon and alloy steel, designed for high-pressure transmission service. Compliant with ASTM A694, they suit oil and gas needs. As of August 22, 2025, 06:19 PM PDT, they are widely used.

These High-Pressure Flanges come in grades F42 to F70, with sizes from 1/2” to 48” and pressure ratings up to 2500 PSI. They withstand temperatures up to 500°C, ideal for demanding applications.

ASTM A694 Flanges undergo tensile, impact, and hydrostatic testing for reliability. Grades like F60 and F70 offer superior strength, making them perfect for oil and gas pipelines as of August 2025.

Compared to standard carbon steel, ASTM A694 Flanges provide higher yield strength, with a service life of 20–40 years when properly maintained, balancing performance and durability.

ASTM A694 Flanges solve challenges like high-pressure leaks and wear in industrial piping, ensuring safety and efficiency as of August 22, 2025.

| Element | F42 (%) | F60 (%) | F70 (%) | Function |

|---|---|---|---|---|

| Carbon (max) | 0.26 | 0.26 | 0.20 | Enhances strength |

| Manganese (max) | 1.60 | 1.60 | 1.40 | Improves toughness |

| Phosphorus (max) | 0.025 | 0.025 | 0.025 | Reduces brittleness |

| Sulfur (max) | 0.025 | 0.025 | 0.010 | Enhances machinability |

| Silicon | 0.15–0.35 | 0.15–0.35 | 0.15–0.35 | Increases strength |

ASTM A694 Flanges leverage these compositions for high-yield strength in high-pressure settings.

| Property | F42 | F60 | F70 | Test Standard |

|---|---|---|---|---|

| Yield Strength (min) | 290 MPa | 415 MPa | 485 MPa | ASTM A370 |

| Tensile Strength (min) | 415 MPa | 515 MPa | 565 MPa | ASTM A370 |

| Elongation (min) | 20% | 20% | 18% | ASTM E8 |

| Hardness (Brinell) | 120–150 HB | 150–180 HB | 180–210 HB | ASTM E10 |

| Temperature Range | -20°C to 500°C | -20°C to 500°C | -20°C to 500°C | N/A |

These properties ensure ASTM A694 Flanges perform reliably under high-pressure conditions.

Supports up to 485 MPa.

Handles up to 2500 PSI.

Lasts 20–40 years.

Meets ASTM A694 standards.

Supports welding and threading.

Enhanced with coatings.

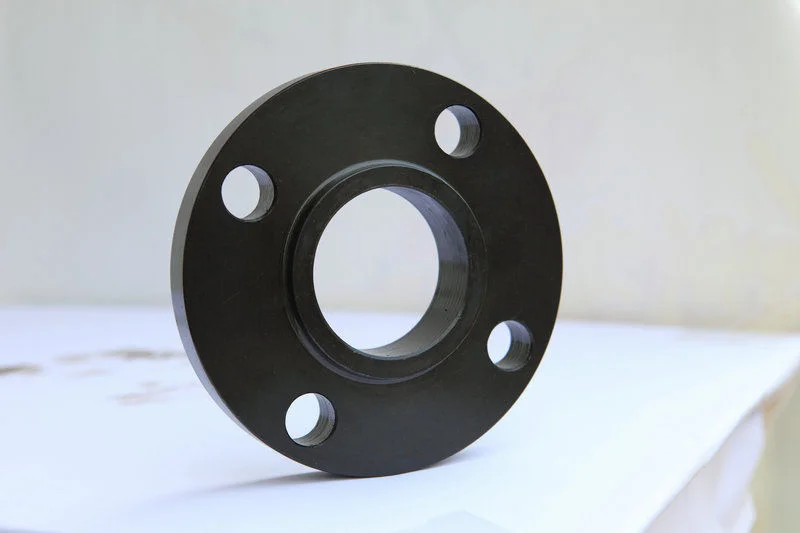

There are six most commonly used flanges, also knows as ANSI Flange, ASME B16.5 Flange. However, these designs can be modified to meet the specific functions and requirements of the applications. Therefore, it’s essential to understand the pressure at the flagged joint, the required strength, and the size of pipes involved. With the correct information comes six types of flanges that an individual can choose from. These include:

Special Flanges

Additionally, the flanges can be modified to form other types, depending on application and functions.

These unique designs are made to incorporate specific needs and applications, like reducing flanges to answer to size and orifice flanges to incorporate orifice mounting.

The most common type, featuring a raised sealing surface that concentrates the bolting force on a smaller area.

Has a flat sealing surface, commonly used with cast iron flanges and for low-pressure applications.

Features a groove for metal ring gaskets (oval or octagonal), providing metal-to-metal sealing.

Features matching tongue and groove surfaces, providing self-alignment and confined gasket area.

Flange faces have to be smooth enough to ensure a tight, leak-free seal for bolted flanges.

| Flange Face Type | Flange Face Type | Flange Face Type |

|---|---|---|

| Type A: flat face | Type D: groove face | Type G: O Ring recess |

| Type B: raised face | Type E: spigot | Type H: O Ring groove |

| Type C: tongue face | Type F: recess |

| ASME B16.5 | Pipe Flanges NPS 1/2 - 24 |

| ASTM A105 | Forged Carbon Steel |

| ASTM A350 LF2 | Low-Temperature Service |

| ASTM A182 | High-Temperature Service |

| ASTM A694 | High-Pressure Transmission |

| DIN EN 1092-1 | European Standard PN 2.5-400 |

Most commonly used, forged with machined surfaces

Corrosion resistant, grades 304, 316, etc.

High-temperature and high-pressure applications

Cast iron, aluminum, brass, bronze, plastic

| Material Category | Fittings (ASTM Grade) | Flanges (ASTM Grade) | Valves (ASTM Grade) | Bolts & Nuts (ASTM Grade) |

|---|---|---|---|---|

| Carbon Steel | A234 Gr WPA | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A234 Gr WPB | A105 | A216 Gr WCB | ||

| A234 Gr WPC | A105 | A216 Gr WCB | ||

| Carbon Steel

Alloy (High-Temperature) |

A234 Gr WP1 | A182 Gr F1 | A217 Gr WC1 | A193 Gr B7 A194 Gr 2H |

| A234 Gr WP11 | A182 Gr F11 | A217 Gr WC6 | ||

| A234 Gr WP12 | A182 Gr F12 | A217 Gr WC6 | ||

| A234 Gr WP22 | A182 Gr F22 | A217 Gr WC9 | ||

| A234 Gr WP5 | A182 Gr F5 | A217 Gr C5 | ||

| A234 Gr WP9 | A182 Gr F9 | A217 Gr C12 | ||

| Carbon Steel

Alloy (Low-Temperature) |

A420 Gr WPL6 | A350 Gr LF2 | A352 Gr LCB | A320 Gr L7 A194 Gr 7 |

| A420 Gr WPL3 | A350 Gr LF3 | A352 Gr LC3 | ||

| Austenitic Stainless Steel | A403 Gr WP304 | A182 Gr F304 | A182 Gr F304 | A193 Gr B8 A194 Gr 8 |

| A403 Gr WP316 | A182 Gr F316 | A182 Gr F316 | ||

| A403 Gr WP321 | A182 Gr F321 | A182 Gr F321 | ||

| A403 Gr WP347 | A182 Gr F347 | A182 Gr F347 |

ASTM standards define the specific manufacturing process of the material and determine the exact chemical composition of pipes, fittings and flanges, through percentages of the permitted quantities of carbon, magnesium, nickel, etc., and are indicated by "Grade".

The usual materials of flanges include stainless steel, carbon steel, aluminum and plastic. The choice of the material largely depends on the purpose of the flange. For example, stainless steel is more durable and is necessary for heavy use. On the other hand, plastic is more feasible for use in the home because of its reasonable price and easy installation. The materials used for flanges are under the designation of the American Society of Mechanical Engineers.

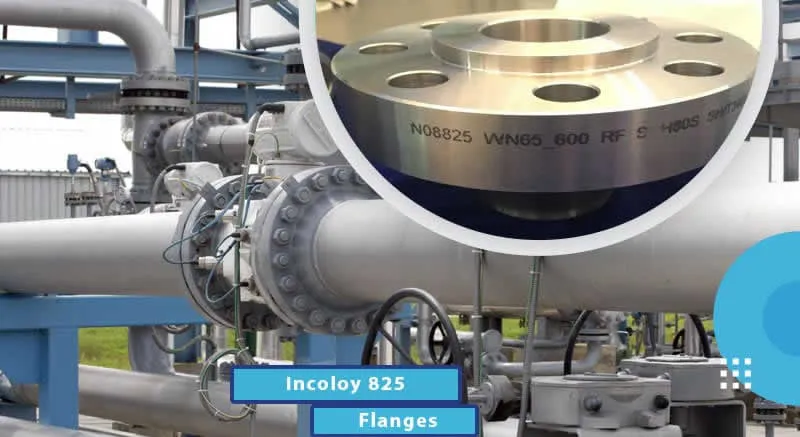

The most common materials for pipe flanges (forged grades) are: ASTM A105 (carbon steel high temperature to match A53/A106/API 5L pipes), A350 Grades LF1/2/3 (carbon steel low temperature to match A333 pipes), A694 Grades F42 to F80 (high yield carbon steel to match API 5L pipe grades), ASTM A182 Grades F5 to F91 (alloy steel flanges to match A335 pipes), A182 Grade F304/316 (stainless steel flanges to match A312 SS pipes), A182 Gr. F44/F51/F53/F55 (duplex and super duplex to match A790/A928 pipes) and various nickel alloy grades (Inconel, Incoloy, Hastelloy, Monel).

The material qualities for these flanges are defined in the ASTM standards.

Metal flanges are classified from 150 to 2500 # rating for different pressure applications.

Incoloy 825 Flange

Industries Using

The basic application of the ASTM A694 Flanges to connect pumps, pipes, valves, and other equipment, often using butt welds, to make a pipework system.

Astm a105 flange is a forged carbon steel flange u...

A105n flanges offer enhanced toughness for high-te...

Mss sp-44 refers to the steel pipeline flanges spe...

Astm a350 (asme sa350) is the standard specificati...