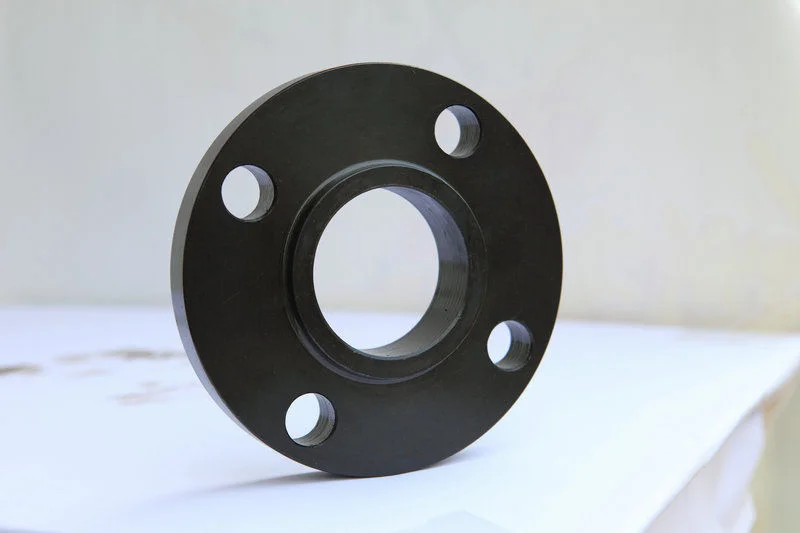

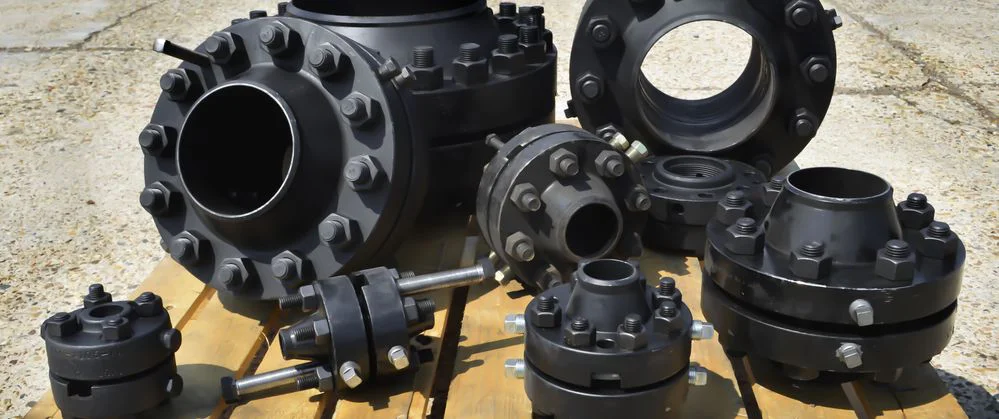

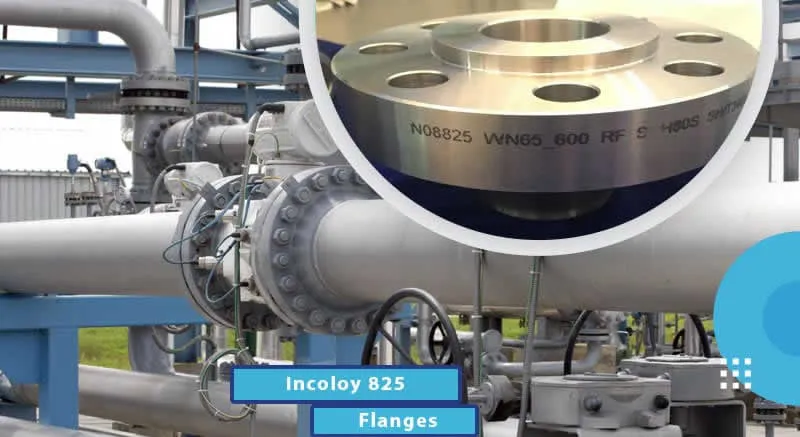

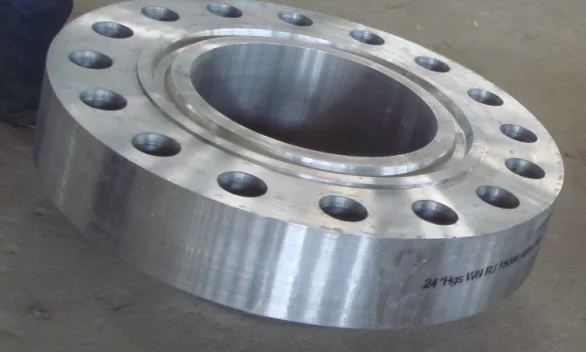

ASTM A105 Flanges are forged from carbon steel, offering durability for high-temperature and moderate-pressure service. Compliant with ASTM A105, they excel in oil, gas, and power industries. As of August 22, 2025, 06:41 PM PDT, they are a trusted choice.

These High-Temperature Flanges range from 1/2” to 48” in size, with pressure ratings up to 2000 PSI and temperature tolerance up to 425°C. They are ideal for demanding industrial applications.

ASTM A105 Flanges undergo tensile, hardness, and hydrostatic testing for quality assurance. Coatings like galvanizing or 3LPE enhance corrosion resistance, making them suitable for oil and gas pipelines as of August 2025.

Compared to alloy steel, ASTM A105 Flanges are more cost-effective while providing robust performance, with a service life of 15–35 years with proper maintenance.

ASTM A105 Flanges address challenges like thermal stress and moderate-pressure needs in industrial piping, ensuring reliability as of August 22, 2025.

Composition of ASTM A105 Flange Material| Element | Percentage (%) | Function |

|---|

| Carbon (max) | 0.35 | Enhances strength and hardness |

| Manganese (max) | 0.60–1.05 | Improves toughness and ductility |

| Phosphorus (max) | 0.035 | Reduces brittleness |

| Sulfur (max) | 0.040 | Enhances machinability |

| Silicon (max) | 0.10–0.35 | Increases strength and elasticity |

ASTM A105 Flanges utilize this composition for reliable performance in high-temperature environments.

Properties of ASTM A105 Flange Material| Property | Value | Test Standard |

|---|

| Tensile Strength (min) | 485 MPa | ASTM A370 |

| Yield Strength (min) | 250 MPa | ASTM A370 |

| Elongation (min) | 22% | ASTM E8 |

| Hardness (Brinell) | 137–187 HB | ASTM E10 |

| Temperature Range | -20°C to 425°C | N/A |

These properties make ASTM A105 Flanges a robust choice for moderate to high-temperature applications.

Comparison of ASTM A105 with Other Flange Standards| Standard | Material | Yield Strength (min) | Temperature Range | Key Application |

|---|

| ASTM A105 | Forged Carbon Steel | 250 MPa | -20°C to 425°C | Oil, Gas, Power |

| ASTM A694 | High-Yield Carbon/Alloy | 290–485 MPa | -20°C to 500°C | High-Pressure Oil & Gas |

| ASTM A182 | Stainless/Alloy Steel | 205–310 MPa | -20°C to 600°C | Chemical, High Corrosion |

| ASME B16.5 | Various (Carbon/Alloy) | Varies (e.g., 250 MPa) | -20°C to 400–600°C | General Industrial Use |

ASTM A105 Flanges offer a cost-effective balance for high-temperature needs, while ASTM A694 suits higher pressure, and A182 excels in corrosion resistance as of August 22, 2025.