Enhanced Toughness Piping Solutions

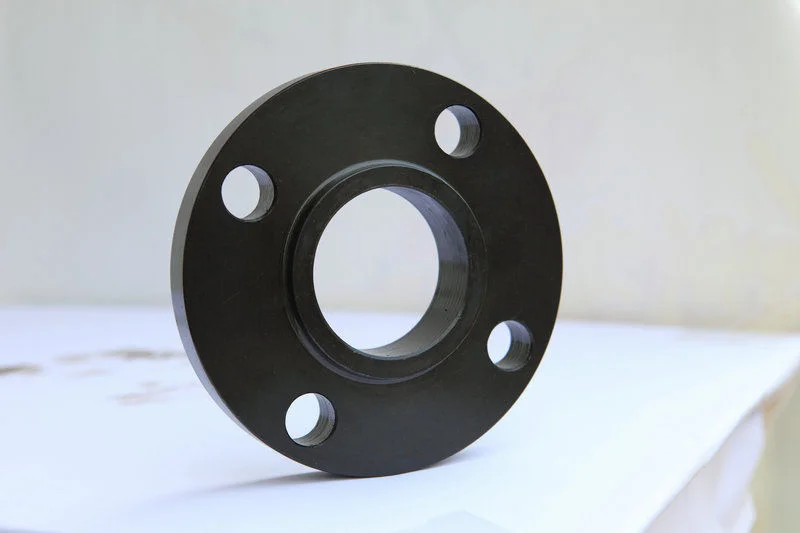

A105n flanges offer enhanced toughness for high-temperature piping, ideal for oil, gas, and power as of august 2025.

Enhanced Toughness Piping Solutions

A105n flanges offer enhanced toughness for high-temperature piping, ideal for oil, gas, and power as of august 2025.

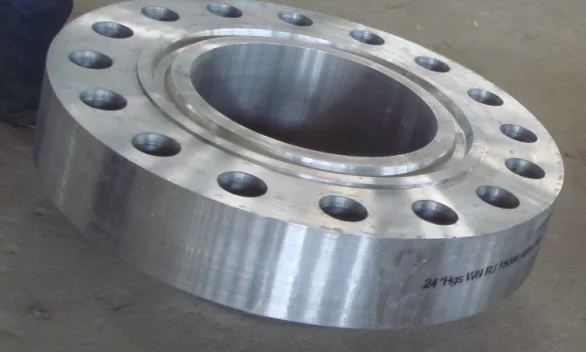

A105N Flanges are normalized forged carbon steel flanges, offering improved toughness for high-temperature and moderate-pressure service. Compliant with ASTM A105N, they suit oil, gas, and power industries. As of August 22, 2025, 07:01 PM PDT, they are a preferred option.

These High-Temperature Flanges range from 1/2” to 48” in size, with pressure ratings up to 2000 PSI and temperature tolerance up to 425°C. Normalization enhances their reliability for demanding applications.

A105N Flanges undergo tensile, hardness, and impact testing for quality. Coatings like galvanizing or 3LPE boost corrosion resistance, making them ideal for oil and gas pipelines as of August 2025.

Compared to standard A105, A105N Flanges offer better toughness due to normalization, with a service life of 15–35 years with proper maintenance, providing a robust yet economical choice.

A105N Flanges tackle challenges like thermal stress and brittle failure in industrial piping, ensuring durability as of August 22, 2025.

| Element | Percentage (%) | Function |

|---|---|---|

| Carbon (max) | 0.35 | Enhances strength and hardness |

| Manganese (max) | 0.60–1.05 | Improves toughness and ductility |

| Phosphorus (max) | 0.035 | Reduces brittleness |

| Sulfur (max) | 0.040 | Enhances machinability |

| Silicon (max) | 0.10–0.35 | Increases strength and elasticity |

A105N Flanges use this composition, with normalization improving their mechanical properties for high-temperature use.

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength (min) | 485 MPa | ASTM A370 |

| Yield Strength (min) | 250 MPa | ASTM A370 |

| Elongation (min) | 22% | ASTM E8 |

| Hardness (Brinell) | 137–187 HB | ASTM E10 |

| Impact Toughness (min) | 20 J at -20°C | ASTM E23 |

| Temperature Range | -20°C to 425°C | N/A |

These properties, enhanced by normalization, make A105N Flanges ideal for high-temperature and impact-resistant applications.

| Standard | Material | Yield Strength (min) | Temperature Range | Key Advantage |

|---|---|---|---|---|

| ASTM A105N | Normalized Carbon Steel | 250 MPa | -20°C to 425°C | Enhanced Toughness |

| ASTM A105 | Forged Carbon Steel | 250 MPa | -20°C to 425°C | Cost-Effective |

| ASTM A694 | High-Yield Carbon/Alloy | 290–485 MPa | -20°C to 500°C | High-Pressure Strength |

| ASTM A182 | Stainless/Alloy Steel | 205–310 MPa | -20°C to 600°C | Corrosion Resistance |

A105N Flanges stand out with normalized toughness, while A105 is more economical, A694 handles higher pressures, and A182 excels in corrosion as of August 22, 2025.

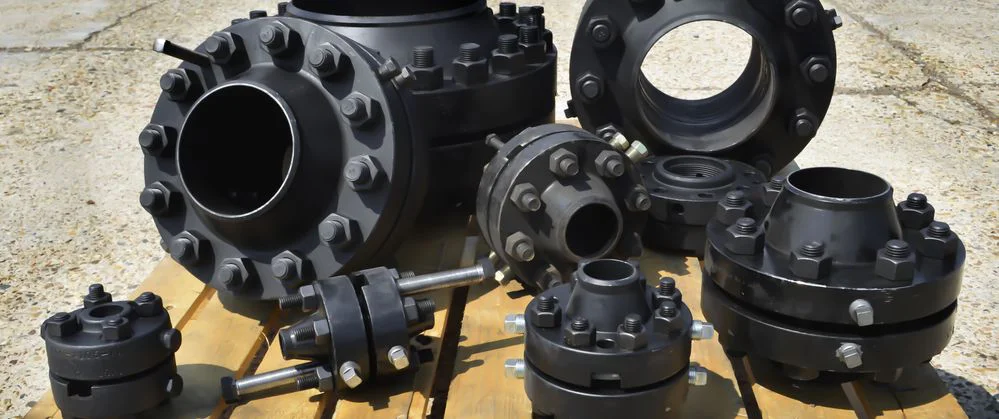

There are six most commonly used flanges, also knows as ANSI Flange, ASME B16.5 Flange. However, these designs can be modified to meet the specific functions and requirements of the applications. Therefore, it’s essential to understand the pressure at the flagged joint, the required strength, and the size of pipes involved. With the correct information comes six types of flanges that an individual can choose from. These include:

Special Flanges

Additionally, the flanges can be modified to form other types, depending on application and functions.

These unique designs are made to incorporate specific needs and applications, like reducing flanges to answer to size and orifice flanges to incorporate orifice mounting.

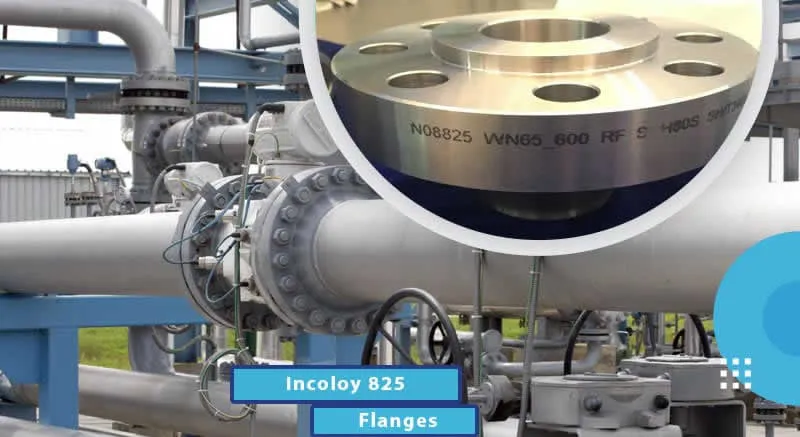

Incoloy 825 Flange

Industries Using

The basic application of the A105N Flange to connect pumps, pipes, valves, and other equipment, often using butt welds, to make a pipework system.

Astm a105 flange is a forged carbon steel flange u...

Astm a694 flanges offer high-yield strength for hi...

Mss sp-44 refers to the steel pipeline flanges spe...

Astm a350 (asme sa350) is the standard specificati...