Reliable Low-temperature Piping Solutions

Astm a350 (asme sa350) is the standard specification for carbon steel and low alloy steel forged flanges and flanged fittings for low temperature services.

Reliable Low-temperature Piping Solutions

Astm a350 (asme sa350) is the standard specification for carbon steel and low alloy steel forged flanges and flanged fittings for low temperature services.

ASTM A350 LF2 Flanges are forged carbon steel flanges engineered for low-temperature service, ideal for oil, gas, and cryogenic applications. Compliant with ASTM A350 LF2, they excel in cold environments. As of August 22, 2025, 07:13 PM PDT, they are a top choice.

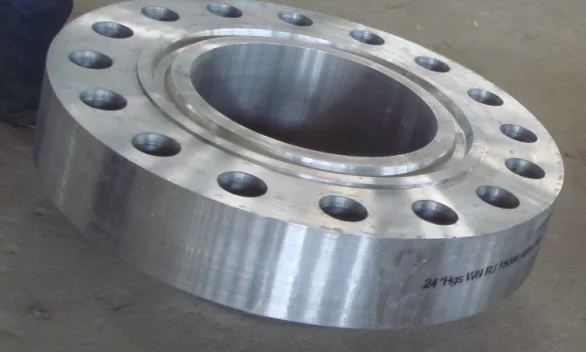

These Low-Temperature Flanges range from 1/2” to 48” in size, with pressure ratings up to 2000 PSI and temperature tolerance down to -50°C. They ensure performance in harsh winter conditions.

ASTM A350 LF2 Flanges undergo tensile, impact, and hydrostatic testing for reliability. Coatings like galvanizing enhance corrosion resistance, making them suitable for cryogenic pipelines as of August 2025.

Compared to standard carbon steel, ASTM A350 LF2 Flanges offer superior toughness at low temperatures, with a service life of 15–35 years with proper maintenance, balancing durability and cost.

ASTM A350 LF2 Flanges address challenges like brittle failure and cold-weather leaks in industrial piping, ensuring safety as of August 22, 2025.

ASTM A350 covers several grades of carbon and low-alloy steel forged or ring-rolled flanges, forged fittings and valves intended primarily for low-temperature service and requiring notch toughness testing. They are made to specified dimensions, or to dimensional standards, such as the ASME and API Specifications referenced in Section 2. Although this specification covers some piping components machined from rolled bar and seamless tubular materials, it does not cover raw material produced in these product forms.

Product furnished in ASTM A350/ ASME SA350 shall conform to the requirements of Specification A961/A961M, including any supplementary requirements that are indicated in the purchase order. Failure to comply with A961/A961M will be considered nonconformance with A350. And in case of conflict between ASTM A350 and A961/A961M, this specification shall prevail.

| Element | Percentage (%) | Function |

|---|---|---|

| Carbon (max) | 0.30 | Enhances strength and hardness |

| Manganese (max) | 0.60–1.35 | Improves toughness at low temperatures |

| Phosphorus (max) | 0.035 | Reduces brittleness |

| Sulfur (max) | 0.040 | Enhances machinability | Silicon (max) | 0.15–0.35 | Increases strength and elasticity |

ASTM A350 LF2 Flanges utilize this composition to ensure performance in low-temperature conditions.

*The sum of Cu, Ni, Cr, V, and Mo shall not exceed 1.00% on heat analysis. The sum of Cr and Mo shall not exceed 0.32% on heat analysis. By agreement, the limit for Nb may be increased up to 0.05 % on heat analysis and 0.06 % on product analysis. The carbon equivalent CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15. For both Class 1 and Class 2 of ASTM A350 LF2, if the maximum thickness of the work piece is less than or equal to 2″, the CE shall not exceed 0.47; if the the maximum thickness of the work piece is greater than 2″, the CE shall not exceed 0.48.

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength (min) | 485–655 MPa | ASTM A370 |

| Yield Strength (min) | 250 MPa | ASTM A370 |

| Elongation (min) | 22% | ASTM E8 |

| Hardness (Brinell) | 137–187 HB | ASTM E10 |

| Impact Toughness (min) | 20 J at -46°C | ASTM E23 |

| Temperature Range | -50°C to 400°C | N/A |

These properties make ASTM A350 LF2 Flanges a reliable choice for low-temperature and cryogenic applications.

| Standard | Material | Yield Strength (min) | Temperature Range | Key Advantage |

|---|---|---|---|---|

| ASTM A350 LF2 | Forged Carbon Steel | 250 MPa | -50°C to 400°C | Low-Temperature Toughness |

| ASTM A105 | Forged Carbon Steel | 250 MPa | -20°C to 425°C | High-Temperature Durability |

| ASTM A694 | High-Yield Carbon/Alloy | 290–485 MPa | -20°C to 500°C | High-Pressure Strength |

| ASTM A182 | Stainless/Alloy Steel | 205–310 MPa | -20°C to 600°C | Corrosion Resistance |

ASTM A350 LF2 Flanges excel in low-temperature toughness, while A105 suits high temperatures, A694 handles high pressures, and A182 offers corrosion resistance as of August 22, 2025.

| Property Category | Technical Value | Test/Reference Standard |

|---|---|---|

| Tensile Strength (Minimum) | 485–655 MPa (Megapascal) | ASTM A370 (Standard for Tension Testing of Steel Products) |

| Yield Strength (0.2% Offset, Minimum) | 250 MPa (Megapascal) | ASTM A370 (Standard for Tension Testing of Steel Products) |

| Elongation (in 50mm Gauge Length, Minimum) | 22% | ASTM E8 (Standard for Tension Testing of Metallic Materials) |

| Brinell Hardness (HB) | 137–187 HB (3000kgf Load, 10mm Ball) | ASTM E10 (Standard for Brinell Hardness Testing of Metallic Materials) |

| Impact Toughness (Minimum) | 20 J (Joule) at -46°C (Charpy V-Notch) | ASTM E23 (Standard for Notched Bar Impact Testing of Metallic Materials) |

| Continuous Service Temperature Range | -50°C to 400°C | N/A (Derived from material composition & industrial application data) |

| Grade / Class | Minimum Impact Value (Average of 3 Specimens) ft-lbf [J] | Minimum Impact Value (Single Specimen) ft-lbf [J] |

|---|---|---|

| LF1 LF9 | 13 [18] | 10 [14] |

| LF2 Class 1 LF3 Class 1 LF5 Class 1 & 2 LF787 Class 2 & 3 LF6 Class 1 | 15 [20] | 12 [16] |

| LF2 Class 2 LF3 Class 2 LF6 Class 2 & 3 | 20 [27] | 15 [20] |

ft-lbf (foot-pound-force) is the imperial unit, [J] (Joule) is the metric unit, ensuring compatibility with global engineering standards.There are six most commonly used flanges, also knows as ANSI Flange, ASME B16.5 Flange. However, these designs can be modified to meet the specific functions and requirements of the applications. Therefore, it’s essential to understand the pressure at the flagged joint, the required strength, and the size of pipes involved. With the correct information comes six types of flanges that an individual can choose from. These include:

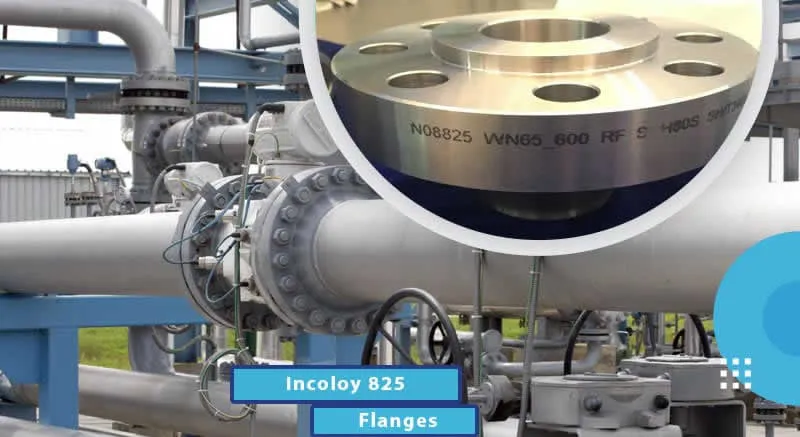

Incoloy 825 Flange

Industries Using

The basic application of the ASTM A350 LF2 Flange to connect pumps, pipes, valves, and other equipment, often using butt welds, to make a pipework system.

Astm a105 flange is a forged carbon steel flange u...

A105n flanges offer enhanced toughness for high-te...

Astm a694 flanges offer high-yield strength for hi...

Mss sp-44 refers to the steel pipeline flanges spe...