| Oil and Gas |

• Pipelines (Crude Oil/Gas Transmission): Stainless steel

Nipoflanges (e.g., ASTM A182 F316) are used for onshore/offshore pipelines,

resisting corrosion from saline environments and hydrocarbon impurities.

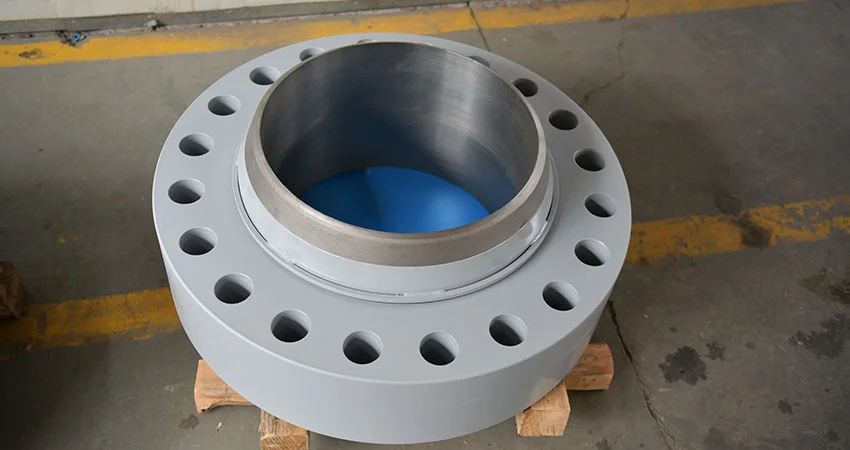

• Wellhead & Processing Facilities: High-pressure Nipoflanges (ASME

B16.5 Class 300/600) adapt to wellhead pressure fluctuations and high-temperature

fluid processing.

|

| Chemical Industry |

• Corrosive Fluid Handling: Duplex/super duplex steel Nipoflanges

(e.g., ASTM A182 F51) or nickel-alloy (Hastelloy) Nipoflanges are used for acids

(sulfuric acid, hydrochloric acid) and solvent pipelines, preventing material

degradation.

• Reactor & Tank Connections: Nipoflanges with tight-seal designs

(raised face/RF) ensure no leakage of toxic or flammable chemicals, complying with

safety standards (e.g., API 598).

|

| Plumbing (Commercial/Civil) |

• Building Water/Gas Piping: Alloy steel Nipoflanges (e.g., ASTM

A350 LF2) or carbon steel (ASTM A105) Nipoflanges are used for indoor plumbing,

balancing cost-effectiveness and resistance to tap water corrosion.

• HVAC Systems: Low-pressure Nipoflanges (Class 150) connect

heating/cooling water pipelines, ensuring stable fluid circulation.

|

| Heating Systems |

• District Heating Networks: Carbon steel Nipoflanges (ASTM A105)

with anti-corrosion coatings (epoxy) are used for high-temperature hot water

(≤120°C) transmission pipelines, resisting scale buildup and thermal stress.

• Residential Boilers: Small-diameter Nipoflanges (NPS 2-4) connect

boiler outlets to heating pipes, ensuring tight sealing to prevent steam leakage.

|

| Water Supply Systems |

• Municipal Water Treatment: Carbon steel Nipoflanges (ASTM A105) or

304 stainless steel Nipoflanges are used for raw water, treated water, and sewage

pipelines, adapting to chlorine disinfection environments.

• Desalination Plants: Stainless steel Nipoflanges (F316L) resist

seawater corrosion in reverse osmosis (RO) water supply lines.

|

| Power Plants (Thermal/Nuclear) |

• Thermal Power: High-temperature alloy Nipoflanges (e.g., ASTM A182

F22) are used for boiler steam pipelines (≤550°C) and turbine connections, complying

with ASME B16.5 for dimensional accuracy.

• Nuclear Power: Nickel-alloy (Inconel) or titanium Nipoflanges are

used in reactor cooling systems, resisting radiation-induced material fatigue and

high-pressure coolant (water/helium) erosion.

|

| Paper and Pulp Industry |

• Pulp Processing Lines: Nipoflanges with wear-resistant materials

(e.g., alloy steel with hard chrome plating) are used for wood pulp, black liquor,

and bleaching agent (chlorine dioxide) pipelines, preventing abrasion from pulp

fibers.

• Drying Section: High-temperature Nipoflanges (Class 150/300)

connect steam-heated drying cylinders, ensuring stable heat transfer for paper

production.

|

| Food Processing Industry |

• Hygienic Piping (Dairy/Beverages): 304/316L stainless steel

Nipoflanges (ASTM A182) with smooth surfaces (polished to Ra ≤ 0.8 μm) are used,

complying with FDA/USDA standards to avoid food residue and bacterial growth.

• Canning & Brewing: Nipoflanges with sanitary gaskets

(silicone/EPDM) connect fruit juice, beer, or canned food processing lines, ensuring

no contamination of edible products.

|

| Manufacturing Industry |

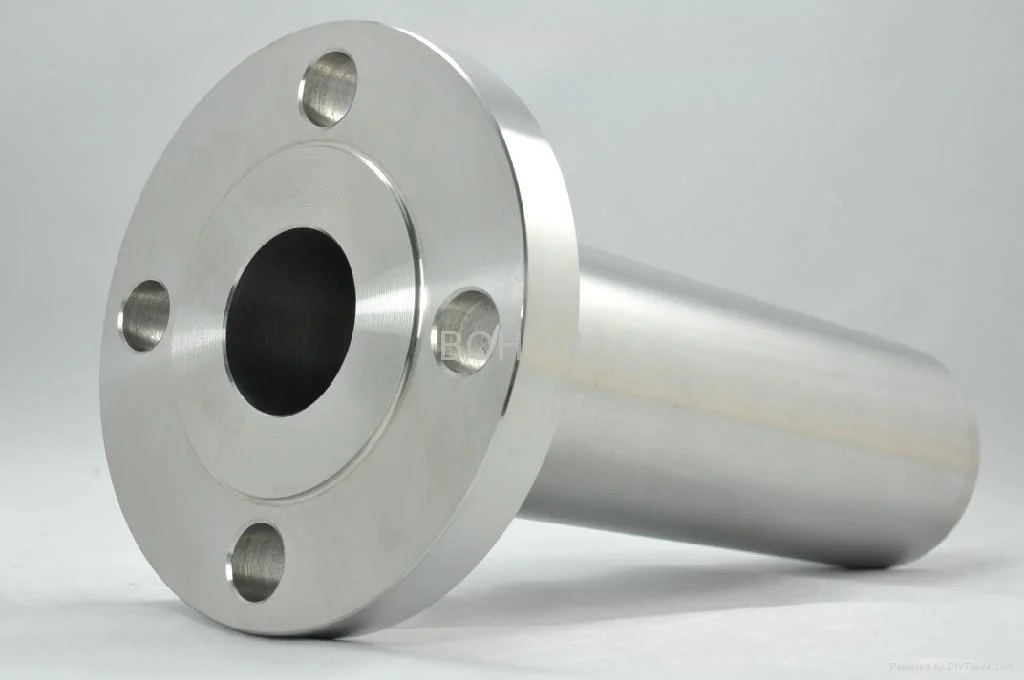

• Automotive/Aerospace: Small-diameter Nipoflanges (NPS 1/2-2)

connect hydraulic oil, coolant, or fuel pipelines in production equipment, ensuring

precise fluid control for machining processes.

• Heavy Machinery: Carbon steel Nipoflanges (ASTM A105) are used for

construction machinery (excavators, cranes) hydraulic systems, withstanding

vibration and mechanical stress.

|

| Structural Pipes |

• Industrial Buildings/Steel Structures: Carbon steel Nipoflanges

(ASTM A105) connect structural support pipes (e.g., for scaffolding, equipment

frames) or fire-fighting pipelines, balancing load-bearing capacity and corrosion

resistance (with galvanized coatings).

• Offshore Platforms: Corrosion-resistant Nipoflanges (stainless

steel or coated carbon steel) connect structural pipes, adapting to marine salt

spray environments.

|

| General Purpose Applications |

• Low-Pressure Fluid Transfer: Carbon steel Nipoflanges (Class 150)

are used for non-corrosive fluids (air, freshwater) in workshops, warehouses, or

small-scale processing facilities, prioritizing cost-effectiveness.

• Equipment Maintenance: Standardized Nipoflanges (ASME B16.5) serve

as replacement parts for aging pipelines or machinery, ensuring compatibility with

existing systems.

|