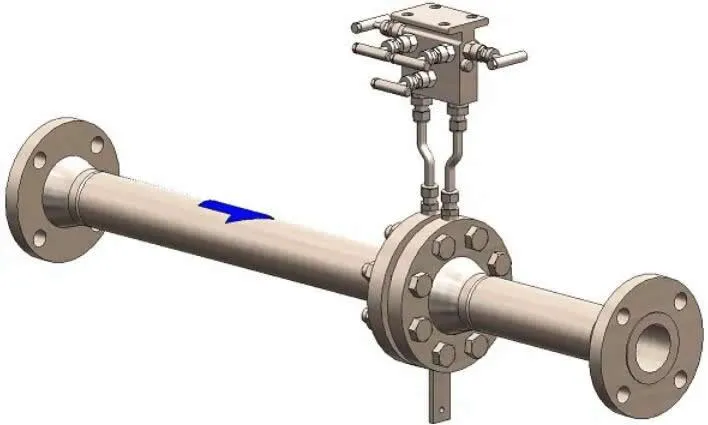

An Orifice Flanges orifice flange is used to measure the flow of the fluid conveyed by the

pipeline via a flow nozzle positioned on the flange itself. Pairs of pressure tappings are machined onto the

orifice flange, making separate tappings on the pipe wall unnecessary.

These Flow Measurement Flanges are available in sizes from 1/2” to 48”, with pressure

ratings from Class 150 to 2500, suitable for temperatures up to 600°C depending on material.

Orifice Flanges feature integrated pressure taps and are forged from materials like carbon

steel or stainless steel, with coatings such as 3LPE enhancing corrosion resistance as of August 2025.

Compared to standard flanges, Orifice Flanges offer superior accuracy in flow measurement,

with a service life of 15–30 years when properly maintained and protected.

Orifice Flanges solve critical challenges like flow rate monitoring and pressure drop

analysis in oil, gas, and chemical industries as of August 22, 2025.

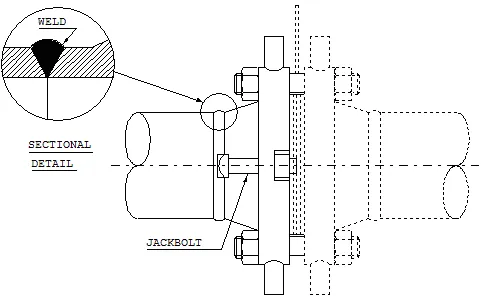

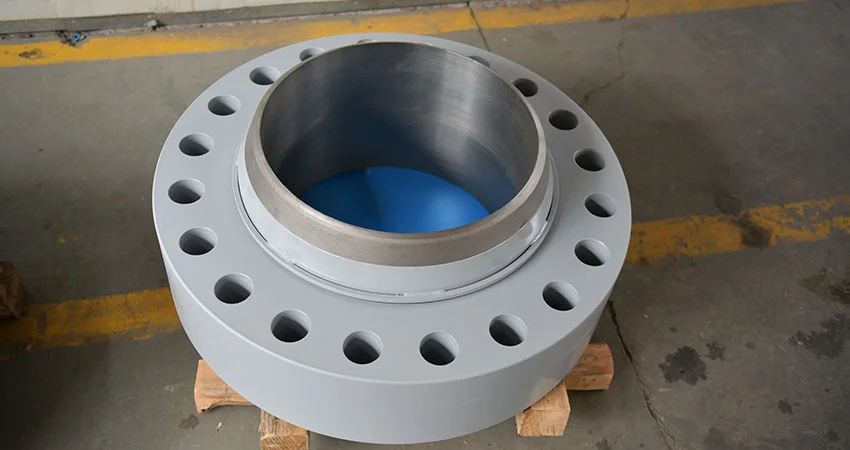

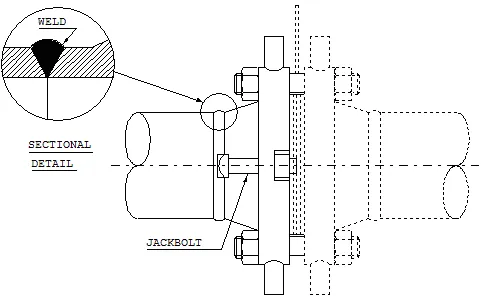

The traditional orifice flange assembly consists of a pair of flanges, orifice plate, bolts, nuts, gaskets,

jacking screws and plugs. Jacking screws ensure the easy removal of the primary flow element.

Orifice flanges are available in all ASTM forged grades (ASTM A105, ASTM A350, ASTM A694, ASTM 182

respectively for carbon, alloy and, stainless steel flanges), dimensions (combinations of nominal sizes and

pressure ratings) and, in socket weld, threaded or weld neck shape (WN is the most used).

Orifice flange for run installation should be so constructed, machined and attached to the that the inner

surface of the passage extends through the orifice flange so that there is no recess at the orifice plate.

Orifice flanges are used instead of the standard pipe flanges when orifice plate or flow nozzle is used. The

basic purpose for this is to measuring the flow rate of either gases or liquids in the respective pipeline.

These flanges are used in various industrial applications and are available in various sizes and materials.

What is an Orifice Flange? Purpose and Applications

An Orifice Flange is used in combination with orifice meters to measure the flow rate

of oil, gas, and other liquids conveyed by the pipeline.

An orifice flange is a type of flange assembly used to measure the flow of products, such as liquids, steam,

or gases, through a piping system. It consists of a pair of flanges, bolts, nuts, gaskets, jack screws, and

plugs The orifice plate, which is a thin plate with a center bore, is installed in the orifice flange to

create a restriction of flow, resulting in a differential pressure that can be used to measure the flow

rate.

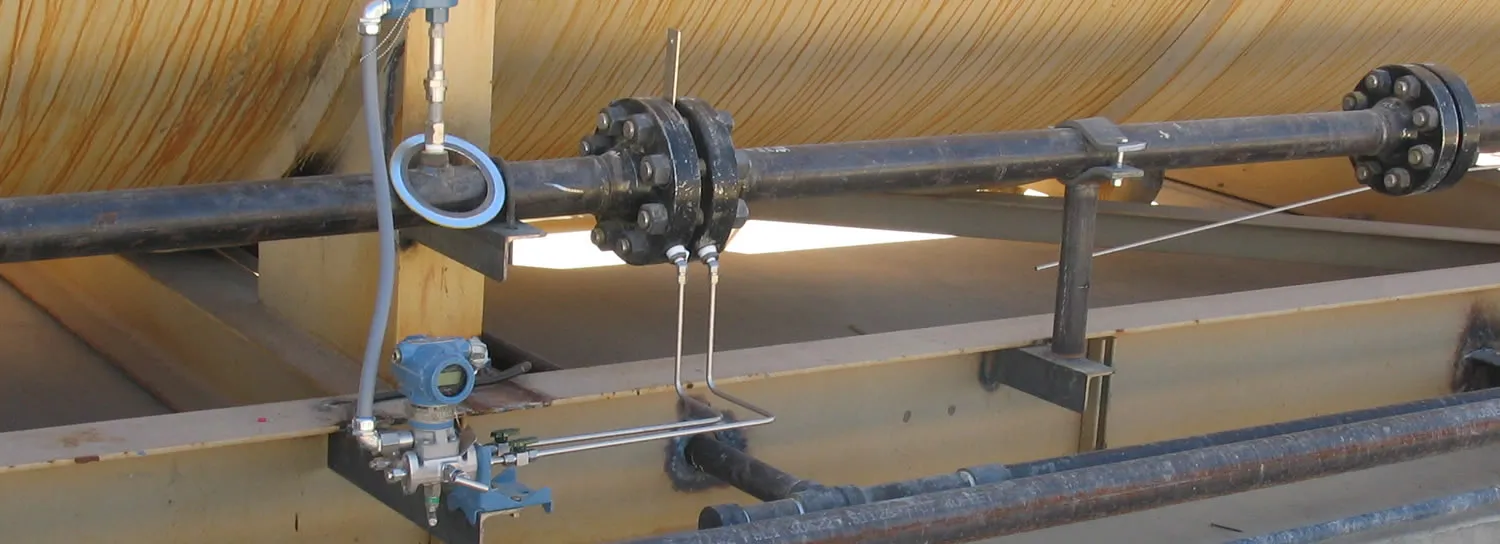

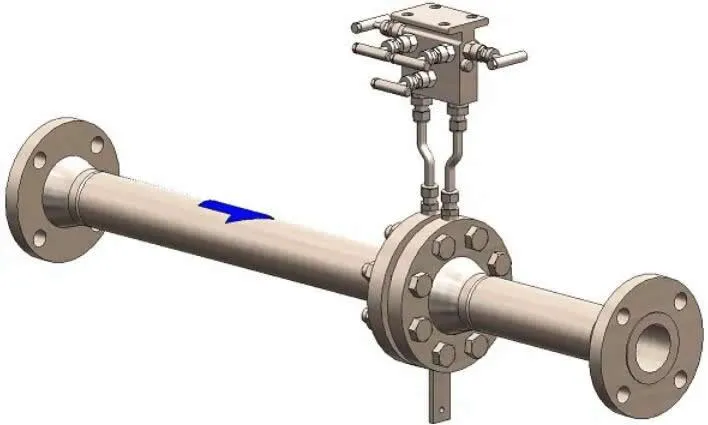

Orifice flanges are typically installed in a straight run of pipe to avoid turbulence at the orifice plate.

According to the American Gas Association, there should be ten pipe diameters upstream of the orifice plate

and five diameters downstream.

The orifice flange sets are available in various sizes and pressure classes, and they are primarily supplied

as raised face weld neck flanges. Other flange facings and types can be supplied upon request to meet

specific needs and requirements.

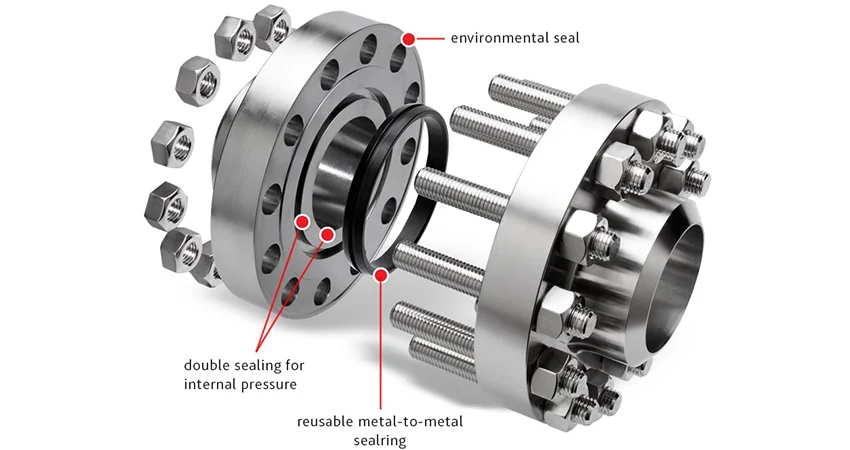

The orifice flange assemblies are designed to ensure accurate centralization of the orifice bore to the

flange bore, following the requirements of standards such as ASME MFC-3M, ASME MFC-14M, AGA 3, and ISO

5167-2.

Orifice flanges are commonly used with orifice meters to measure the flow rate of liquids or gases in a

pipeline. They are manufactured with high-quality materials and comply with applicable industry standards.

Orifice flanges are available in all ASTM forged grades (ASTM A105, ASTM A350, ASTM A694, ASTM 182

respectively for carbon, alloy and, stainless steel flanges), dimensions (combinations of nominal sizes and

pressure ratings) and, in socket weld, threaded or weld neck shape (WN is the most used).

Orifice Flange manufacturer Sunny Steel supplies Orifice Flanges, Plate Flanges,

Orifice flange installation

Orifice flanges, abbreviated as ORFF, are for metering the volumetric flow rate of liquids and gasses through

a pipe. Two orifice flanges are called an orifice flange union. Each flange comes with two pipe taps for

measuring the pressure drop of the flow through an orifice plate. Orifice plates do not come with the

flanges and are sized based on the requirements of the process. Two jack screws are used to spread the

flanges apart in order to change the orifice plate. This flange is normally available in weld neck, slip-on,

and threaded flanges. These flanges have a raised face.

Orifice flanges are installed in a straight run of pipe in order to avoid turbulence at the plate. As a rule

of thumb, an orifice flange has ten diameters of straight pipe upstream and five diameters of pipe

downstream. There are guidelines set out in (American Gas Association) AGA Report #3 which is the Orifice

Metering of Natural gas.

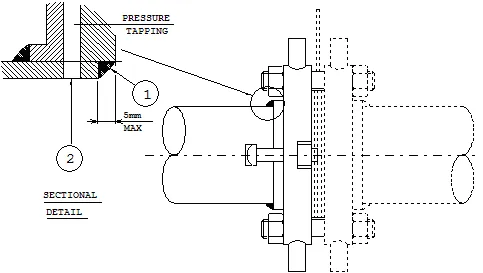

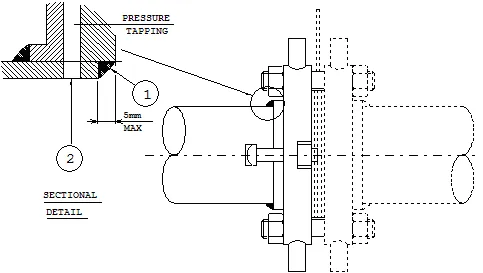

When installing the orifice plate flange the pressure taps need to be at the same elevation to each other.

The assumption when making the calculation for the orifice plate is that static head of the tubes is the

same on both sides of the orifice plate. Pressure taps should not be installed facing down as the taps could

become plugged with debris in the line.

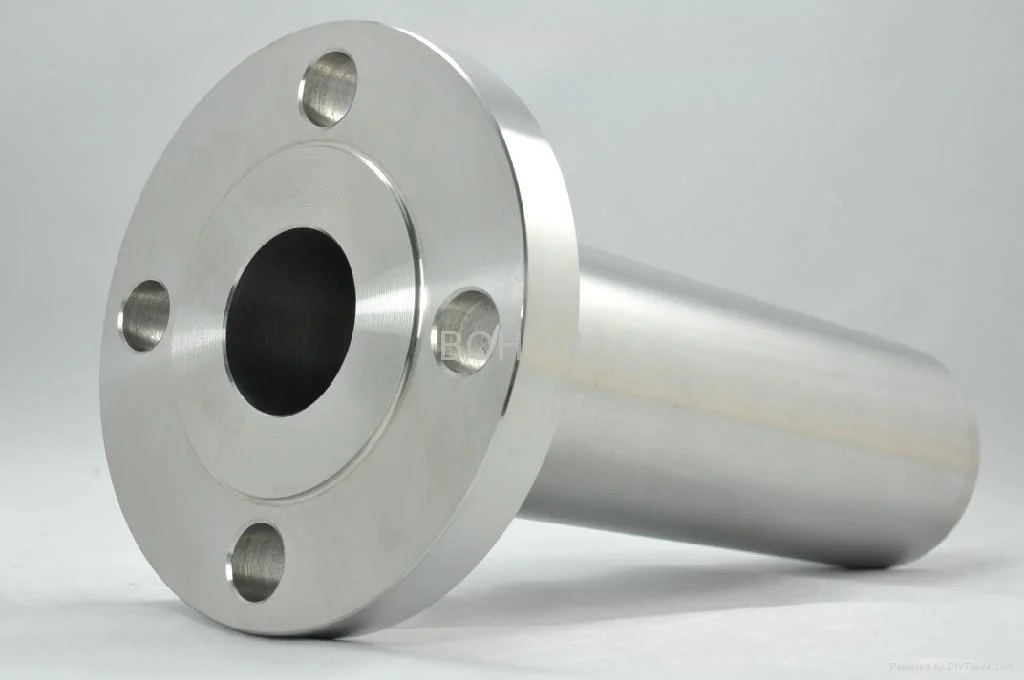

Weldneck orifice flanges are butt-welded into the pipeline. The inside diameter (bore diameter) of the pipe

should be specified when ordering. Weldneck orifice flanges are available in ANSI classes 300, 600, 900,

1500 and 2500. They are not available in ANSI 150 sizes because the thickness of ANSI 150 flanges are not

enough to allow for drilling pressure taps.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges

are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2″ NPT

tappings in each flange.

ASME B16.36 covers Dimensions and dimensional tolerances from orifice flanges (similar to those covered in

ASME B16.5) that have orifice pressure differential connections.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges

are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2″ NPT

tappings in each flange.

Orifice flange assembly

Special Flanges

Orifice flange assembly

It consists of an Orifice Plate with union flange. Used in the piping system to

measure the flow of liquids and gases through the Orifice Plate.

It incorporates the 1/2″ NPT or SW pressure taps into the flanges, as requested by the

customer.

This flow meter can be applied to a wide variety of measurements, involving most gases and

liquids, including fluids with solids in suspension, as well as viscous fluids over a wide

range of temperature and pressure. It can be applied in any tube size. According to ISO 5167

and AGA-3 Standards.

Drawing of orifice flanges

Orifice Flanges generally come with either Raised Faces or RTJ (Ring Type Joint) facings.

They are, for all intensive purposes, the same as weld neck and slip on flanges with extra machining.

Orifice flange for run installation should be so constructed, machined and attached to

the that the inner surface of the passage extends through the orifice flange so that there is no recess

at the orifice plate.

The flange bore and the section of pipe shall be of the same internal diameter.

Weldneck and Slip-On Orifice Runs

Weld Neck Orifice Run