Anchor Flanges are robust steel flanges designed to provide structural support and stability in high-pressure piping systems, adhering to ASME B16.5 standards as of August 23, 2025, 06:14 PM PDT. These Piping Stability Flanges ensure secure anchoring.

Available in sizes from 1/2” to 48”, Anchor Flanges support pressure ratings up to Class 2500 and temperature tolerances up to 650°C, depending on material, ideal for demanding environments.

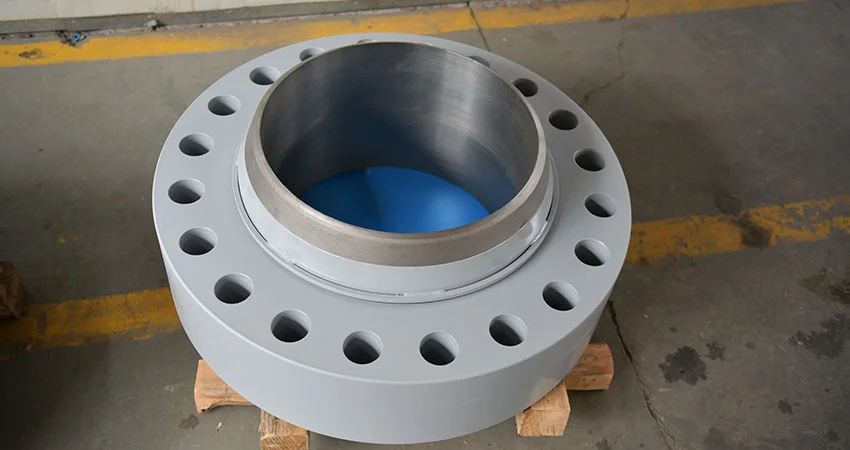

Forged or machined with reinforced designs, these flanges offer exceptional durability, with coatings like FBE or galvanizing enhancing corrosion resistance as of August 2025. They are built for longevity.

Compared to standard flanges, Anchor Flanges provide superior stability for pipelines, offering a service life of 20–40 years with proper maintenance and protective measures.

Anchor Flanges address challenges like pipeline movement and vibration, delivering reliable high-pressure flange support as of August 23, 2025.

Quality Standard for Anchor Flanges

High quality Anchor Flanges all made and controlled to the relevant standards such as: ASME, ASTM, BS and DIN/WERKSTOFFE.

Sizes for Anchor Flanges

- All Anchor Flanges are available available in sizes from 1/4” through to any size.

- Wall Thickness for Anchor Flanges

- Schedule 5s through to Schedule XXS and heavier.

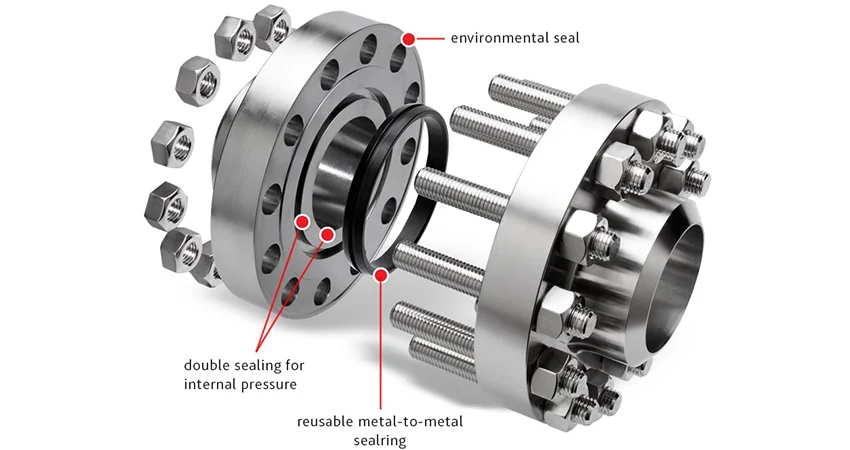

Welded into the line and encased in concrete, they immobilize the pipe at predetermined locations and transfer built-up stresses to external structures. For example, in cross-county pipelines end forces of considerable magnitude are generated by internal pressure and temperature changes. A 24″ O.D. x 0.594″ wall pipe in a pipeline operating at 1100 psi and subjected to a 90° rise in metal temperature, for example, will develop total thrust of 1,000,000 lbs.

Unless these forces are properly controlled, they can damage pumps, valves and other close-tolerance equipment. Anchor Flange may be used to secure subsea piping and risers to platform structures.

The Anchor flange is designed for immobilization of high pressure pipe lines.

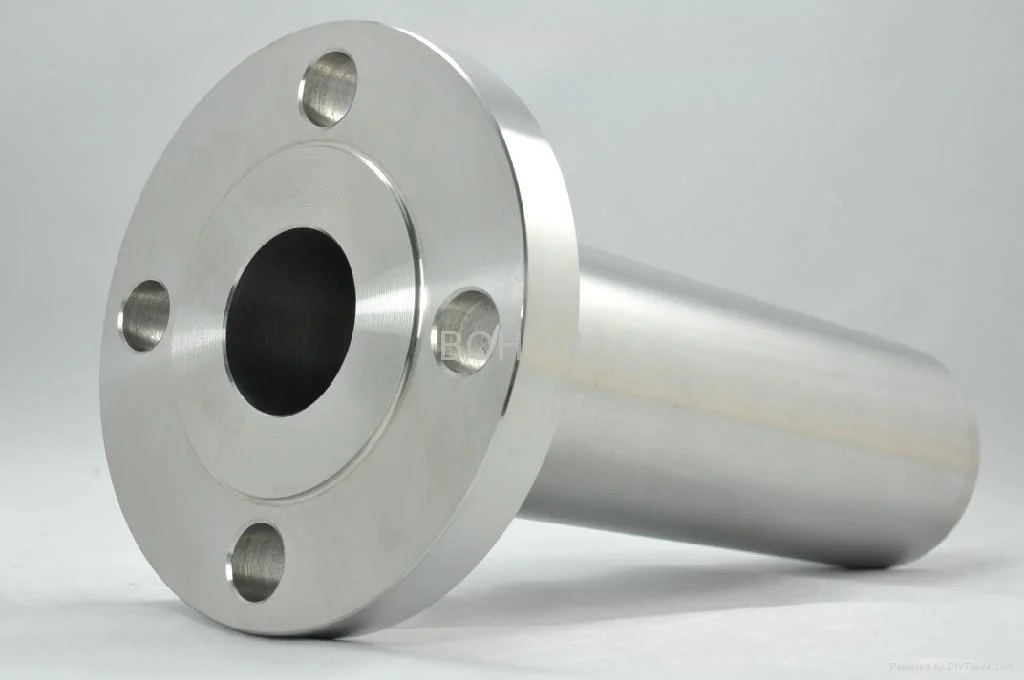

The Anchor flange is a one-piece combination reducer and welding neck flange designed expressly for effecting pipe size increases at flanged connections to pumps, valves, compressors and other equipment. It provides a more compact, more efficient and frequently a more economical means than is permitted by the conventional two-piece combination of a concentric reducer and welding neck flange.

Ordering Information for Anchor Flanges

The following information must be provided while ordering an anchor flange.

- Nominal pipeline size and wall thickness

- Pipeline material details

- Design code

- Design temperature and pressure

- Corrosion allowance

- Installation temperature

- Allowable concrete bearing stress

- Maximum axial load

- Other applicable moments and load information

Orifice flanges, abbreviated as ORFF, are for metering the volumetric flow rate of liquids and gasses through

a pipe. Two orifice flanges are called an orifice flange union. Each flange comes with two pipe taps for

measuring the pressure drop of the flow through an orifice plate. Orifice plates do not come with the

flanges and are sized based on the requirements of the process. Two jack screws are used to spread the

flanges apart in order to change the orifice plate. This flange is normally available in weld neck, slip-on,

and threaded flanges. These flanges have a raised face.

Orifice flanges are installed in a straight run of pipe in order to avoid turbulence at the plate. As a rule

of thumb, an orifice flange has ten diameters of straight pipe upstream and five diameters of pipe

downstream. There are guidelines set out in (American Gas Association) AGA Report #3 which is the Orifice

Metering of Natural gas.

When installing the orifice plate flange the pressure taps need to be at the same elevation to each other.

The assumption when making the calculation for the orifice plate is that static head of the tubes is the

same on both sides of the orifice plate. Pressure taps should not be installed facing down as the taps could

become plugged with debris in the line.

Weldneck orifice flanges are butt-welded into the pipeline. The inside diameter (bore diameter) of the pipe

should be specified when ordering. Weldneck orifice flanges are available in ANSI classes 300, 600, 900,

1500 and 2500. They are not available in ANSI 150 sizes because the thickness of ANSI 150 flanges are not

enough to allow for drilling pressure taps.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges

are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2″ NPT

tappings in each flange.

ASME B16.36 covers Dimensions and dimensional tolerances from orifice flanges (similar to those covered in

ASME B16.5) that have orifice pressure differential connections.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges

are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2″ NPT

tappings in each flange.

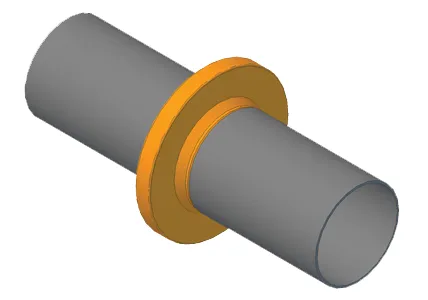

One of the common characteristics of a metal pipeline is the inherent

movement caused by fluid flow, as well as

expansion and contraction from temperature changes.

When a pipeline makes a sharp turn, the fluid attempts to

push the pipe in the direction of flow. By installing an

anchor flange and securing it into a

reinforced concrete block buried deep underground,

these forces are safely transferred to the earth.

For large-diameter, high-pressure, long-distance oil and gas pipelines,

anchor flanges serve as critical structural supports. They are typically

installed underground or buried to ensure stability and

long-term performance.

Copper Plated Anchor Flange

Special Flanges

What is an anchor flange?

Anchor Flange is a device that is installed on the lines of the piping system to deal with the axial movement and prevent the movement of the pipeline.

So, in the continuation of this article, we will discuss the applications, features and raw materials of this type of flange.

Finally, Anchor Flange is a type of flange that is mainly used to connect pipes to other structures. This type of flange is usually made of carbon steel, alloy steel and stainless steel.