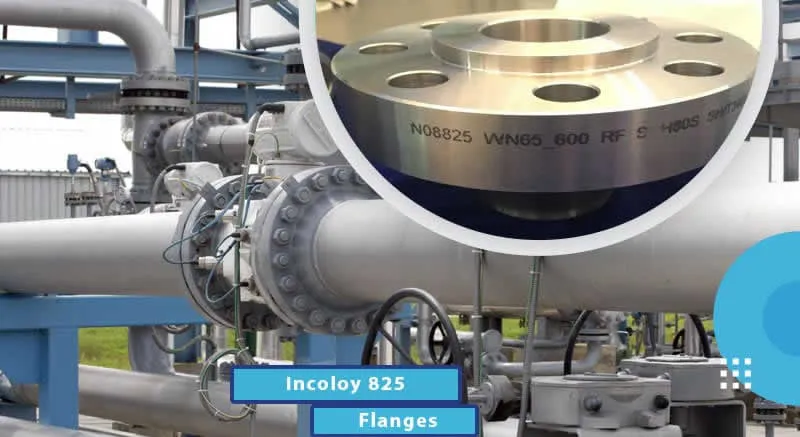

Custom Flanges are tailored steel flanges designed to meet specific industrial requirements, adhering to ASME B16.5 and other standards as of August 23, 2025, 06:54 PM PDT. These Tailored Piping Flanges offer precision fit.

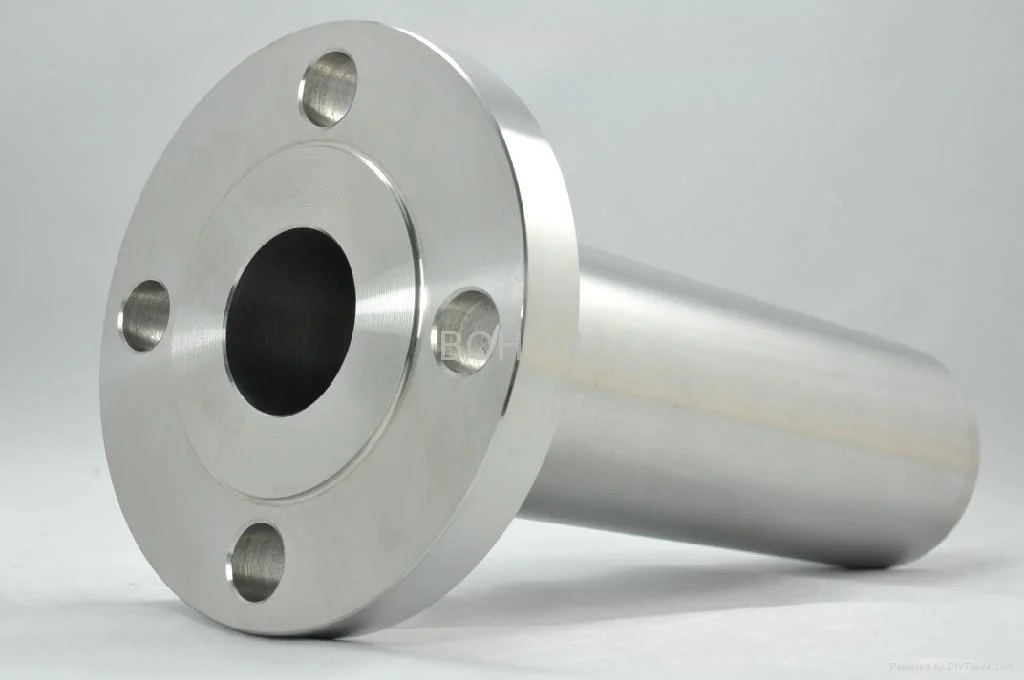

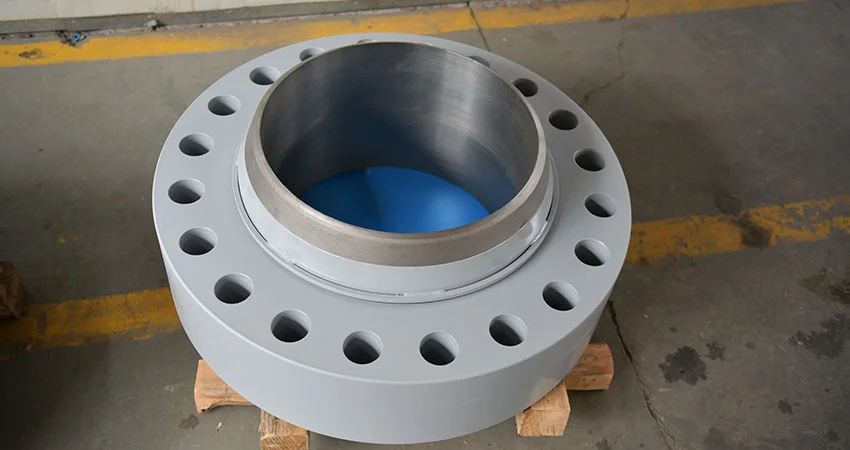

Available in custom sizes from 1/2” to 60” and pressure ratings up to Class 2500, Custom Flanges accommodate temperatures up to 700°C, depending on material, for unique applications.

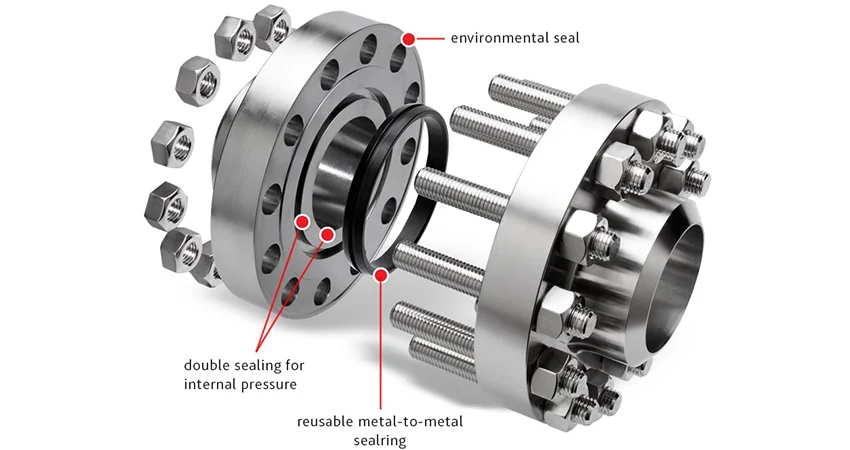

Fabricated through advanced forging or machining, these flanges provide exact specifications, with coatings like 3LPE or galvanizing enhancing corrosion resistance as of August 2025. Customization is key.

Compared to standard flanges, Custom Flanges offer unmatched adaptability, with a service life of 15–40 years based on design and maintenance practices.

Custom Flanges address specific challenges like unique pipe layouts and extreme conditions, delivering reliable industrial piping customization as of August 23, 2025.

We also provide custom flange templates for you to modify to your liking to get a better understanding of your application. Additionally, drawings for approval can be requested prior to actual manufacturing, provided an order already stands. This gives you an opportunity to have one final review of your incoming product before we throw your forging onto the machines.

Anyone can provide standard commodity B16.5 flanges, but not everyone can make them in small quantities with a quick turn-around when something needs to be modified past typical industry requirements.

Although we do not directly design custom flanges, we do provide custom flanges to your requirements. We do not always have a standard for reference if your job isn’t to ASME code, and so we have to confirm all the dimensions with you. When you order a custom flange, please show all the details or requirements to our sales staff to ensure our quotation will be accurate.

Common flange standards and specifications

Special flanges and fittings and custom forgings can be designed to meet any number of unique specifications and standards. Some common classifications for custom pipe flanges include:

- AWWA, the American Water Works Association

- ASME, the American Society of Mechanical Engineers

- ANSI, the American National Standards Institute

- CL 125 lightweight

- Tube turns

- Large industry standard

- Metric system flanges

FAQs

Custom Flanges are tailored steel flanges meeting specific industrial needs, compliant with ASME B16.5 as of August 23, 2025.

Custom Flanges range from 1/2” to 60” or more, based on custom specifications.

Custom Flanges offer a minimum tensile strength of 515 MPa and yield strength of 205 MPa, varying by design.

Use Custom Flanges for unique piping needs in refineries, power plants, or water systems.

Custom Flanges are installed via welding or bolting, tailored to specific designs.

Custom Flanges offer tailored fits, while Standard Flanges follow fixed specifications.

Custom Flanges last 15–40 years with proper maintenance, depending on design as of August 2025.

Custom Flanges are used in oil refineries, petrochemical plants, power generation, and water systems.

Custom Flanges can handle high temperatures up to 700°C with appropriate materials.

Maintain Custom Flanges with regular inspections, coating upkeep, and pressure tests.