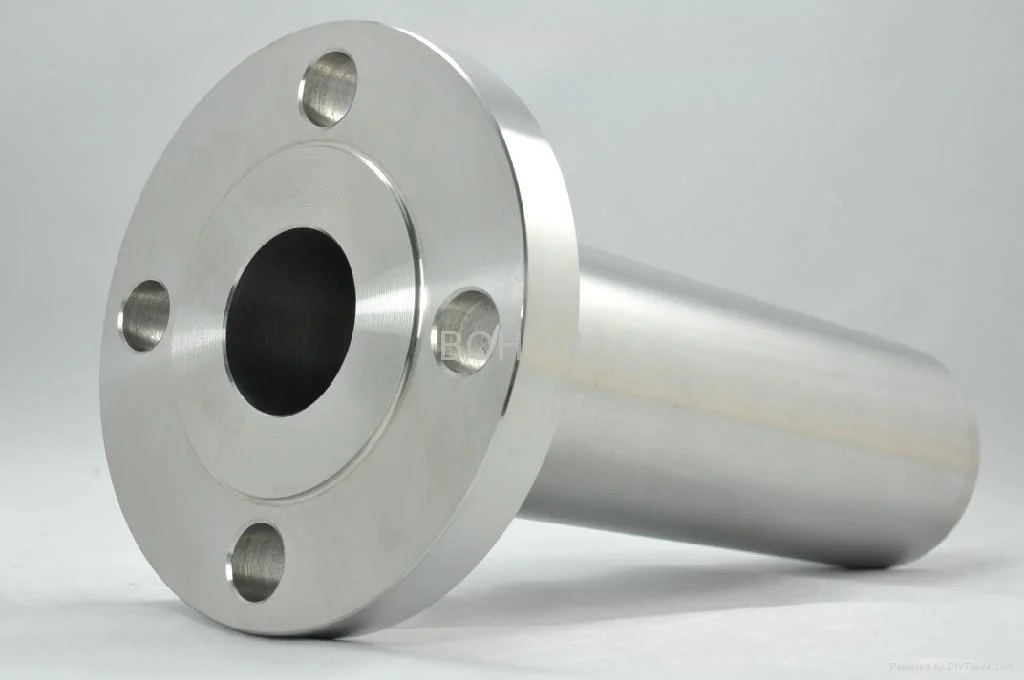

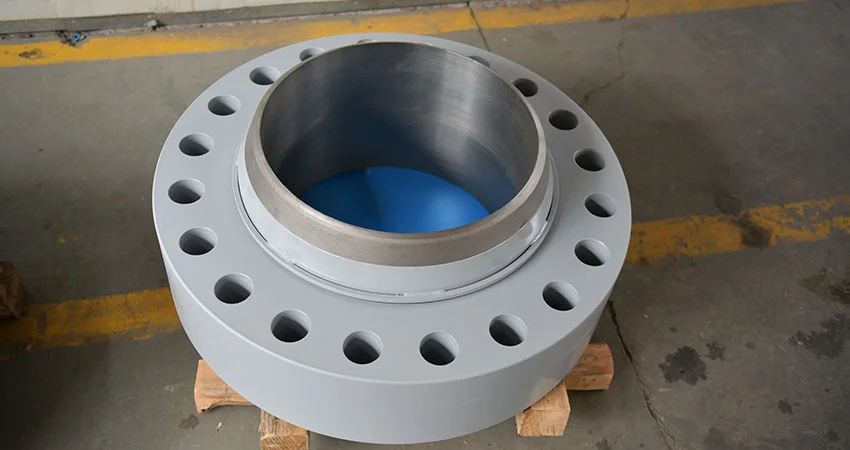

Spectacle Blind Flanges are versatile steel flanges designed for isolating or connecting piping sections, adhering to ASME B16.5 standards as of August 24, 2025, 08:44 PM PDT. These Piping Isolation Flanges ensure safety.

Available in sizes from 1/2” to 48” with pressure ratings up to Class 2500, Spectacle Blind Flanges handle temperatures up to 600°C, depending on material, for robust applications.

Crafted via forging with a unique spectacle design, these flanges offer dual functionality (open or blind), with coatings like FBE or galvanizing enhancing corrosion resistance as of August 2025. Isolation is seamless.

Compared to standard blind flanges, Spectacle Blind Flanges provide flexibility, with a service life of 15–35 years with proper maintenance and protective measures.

Spectacle Blind Flanges address challenges like pipeline isolation and safety, delivering reliable industrial pipeline isolation as of August 24, 2025.

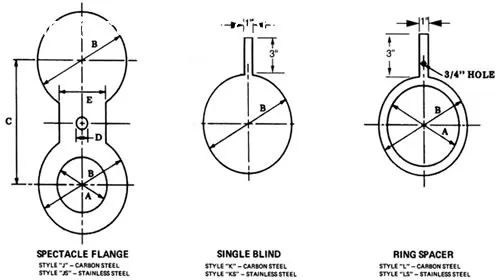

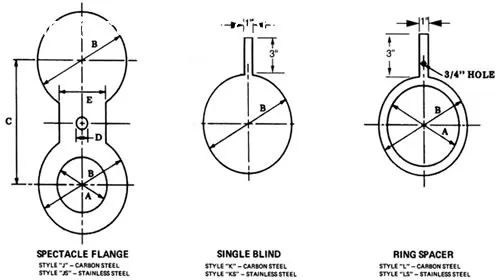

A spectacle flange is a specialty flange made of two metal discs attached in the middle by a small section of steel. Spectable flanges get their name because they look like a pair of reading glasses, or spectacles. Spectacle flanges, also known as spectacle blind flanges, are most commonly used on piping systems that need to be separated regularly or where the flow through the systems is regularly stopped. One end of the spectacle flange is solid, while the other end has a hole in the center. The spectacle flange can be rotated to place either the solid or hollow end within the pipe system, thereby opening or closing the flow.

Advantages of Spectacle Flanges

- Spectacle flanges require no welding for installation

- Spectacle flanges from Sunny Steel Flange have a wide range of pressure tolerances

- Sunny Steel will manufacture spectacle flanges to your specifications

For pipe Flanges-regularly seperated for isolation, maintenance or reasons, a spectacle extrudes Solution. Typically, spec blinds was mounted in the open position so-your flow pipe operates and is normally. Blinds is mounted onto one of the $number so is need to isolate a, it ' s easy!

Flange spade vs Spectacle blinds

A spectacle blind combines a flange spade and a ring spacer in a single device (this is the reason why flange spades are called “single-blinds” or “blanks”). The difference is that spectacle blinds may need some space to be rotated, and this space is not always available due to the routing of the piping system. This is when two separate devices are used, as they do not require rotation to be installed.

Spades, ring spacers, and spectacle blinds are available in multiple sizes (from 1/2 inch to 24 inches, and pressure rating from 150 to 2500#) and material grades (the same available for standard flanges) depending on the fluid conveyed by the pipeline.

The difference between spades/ring spacers and spectacle blinds is shown in the image:

Spades and Spectable blinds

Ring spacer

Ring spacers are bored to the matching pipe id and are the same thickness as the “single blind” that it replaces. When removing a “single blind”, either the flange and associated piping must be pulled together to seal the line, or a “ring spacer” must be installed to fill the gap. Thick single blinds or rigid piping systems normally require ring spacers.

Single/ line blind or blank

A positive shut-off device normally installed adjacent to, or in conjunction with, a valve. Their purpose is to prevent accidental flow through a pipeline to a vessel. With the exception of cast iron, plastic, or fiberglass services, they are not drilled with bolt holes, but fit inside the bolt circle of mating flanges. Pipeline blinds or blanks are not the same as bolting blind flanges. Single blinds use standard gaskets.

A combination of a “single blind’ and a “ring spacer” can be fabricated for field convenience as a single unit. Weight consideration and the associated difficulty of handling heavy pieces in the field are a primary consideration in specifying a “spectacle blind” or a combination of blinds. Spectacle blinds are meant to be rotated to change blind/spacer orientation.

Spectacle blind

A spec blind is a combination of a ring spacer and single blind. They are usually permanently installed in a piping system and rotated as needed.

Test blank

A test blank is specially designed blank used for hydrostatic or other incompressible fluid testing purposes only. Their advantage is cost and weight savings since higher allowable stress values (or lower safety factors) are used in their design.

Vapor blind

Similar to a “single blind”, but thinner, normally 1/8″ (3mm) to 5/16″ (8mm) thick. These are positive sealing devices intended to prevent accidental flow or leakage of vapors into a pipeline or vessel, usually while the system is in service.

One end of the blind will have an opening to allow flow through the pipe during operation and the other end is solid to block flow during maintenance.

Comparison of Spectacle Blind Flanges with Other Standards

| Standard/Type |

Material |

Size Range |

Pressure Rating |

Key Advantage |

| Spectacle Blind Flanges |

Carbon/Stainless Steel |

1/2”–48” |

Up to Class 2500 |

Dual Isolation Functionality |

| ASME B16.5 |

Forged Steel |

1/2”–24” |

Class 150–2500 |

Standardized Design |

| MSS SP-44 |

Forged Steel |

NPS 12–60 |

Class 150–900 |

Heavy-Duty Applications |

| Blind Flange |

Carbon Steel |

1/2”–48” |

Class 150–2500 |

Complete Closure |

Spectacle Blind Flanges offer dual functionality, while ASME B16.5 provides standardization, MSS SP-44 suits large pipes, and Blind Flanges ensure full closure as of August 24, 2025.