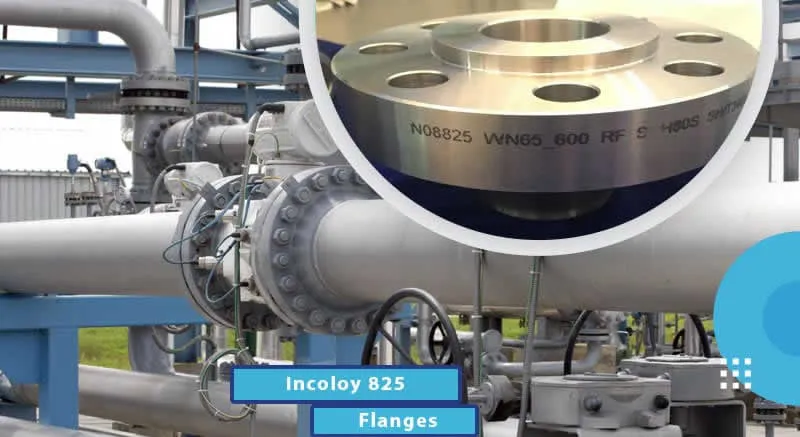

Large Diameter Flanges are robust steel flanges designed for heavy-duty piping systems,

adhering to ASME B16.5 and other standards as of August 24, 2025, 11:40 PM PDT. These Heavy-Duty

Piping Flanges ensure strength.

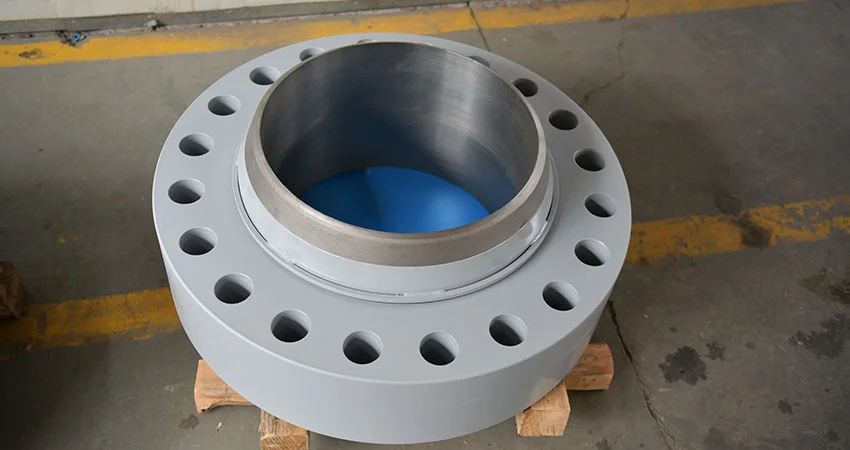

Available in sizes from 24” to 120” with pressure ratings up to Class 2500, Large Diameter

Flanges support temperatures up to 650°C, depending on material, for large-scale applications.

Forged or machined with reinforced designs, these flanges offer exceptional durability, with coatings like

3LPE or galvanizing enhancing corrosion resistance as of August 2025. Reliability is

paramount.

Compared to standard flanges, Large Diameter Flanges provide superior load-bearing

capacity, with a service life of 20–40 years with proper maintenance and protective coatings.

Large Diameter Flanges address challenges like high-pressure and large-volume piping,

delivering reliable high-capacity piping solutions as of August 24, 2025.

A Large Diameter flange is a metal ring that is used to connect valves, pipes, pumps and other equipment that

is necessary to form pipelines. The Large Diameter flange also allows people to have easy inspection, rapid

modification, and easy and quick access to clean the pipes.

Large Diameter Flanges Finished

Natural, Nickel Plated, Electro Polished Plated or any coating as per customer specification.

Any kind of special die casting sand gravity die lost wax shell moulding castings and cast parts casting

produced to user specifications. We can be more competitive than Chinese castings and cast parts made in

China Taiwan Asia Korea as traditional Indian expertise in Brass castings and Brass casting is superior and

Indian Carbon Steel foundry / foundries are more competitive than other S.S. Carbon Steel foundries.

What Materials Are Flanges Made From?

The most typical material used for making large diameter flanges is carbon steel that has been forged

carefully and which surfaces have been machined.

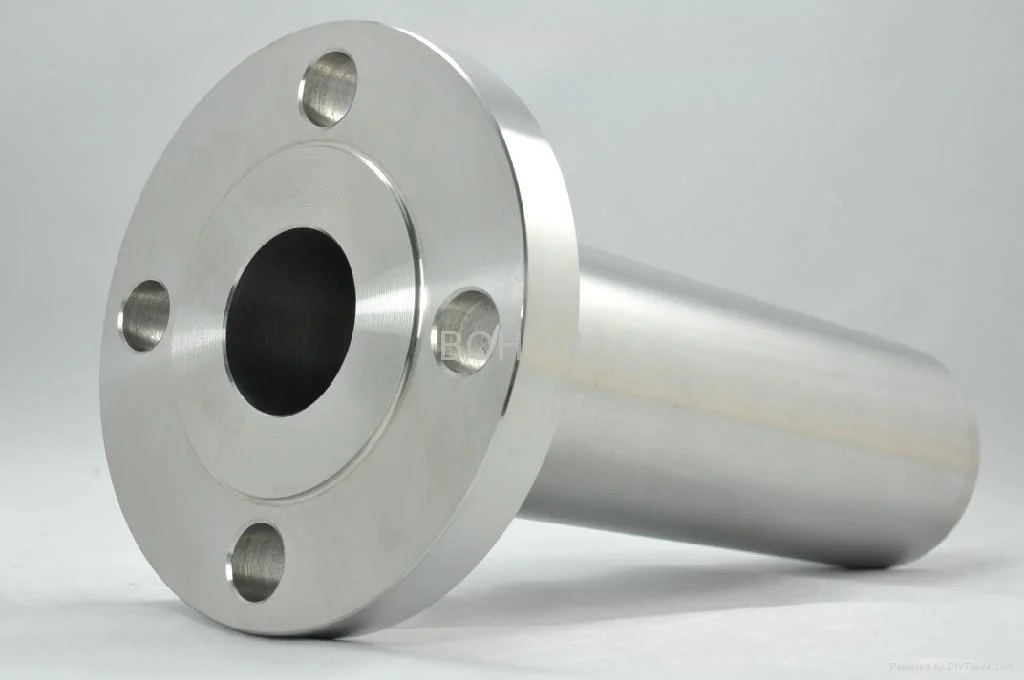

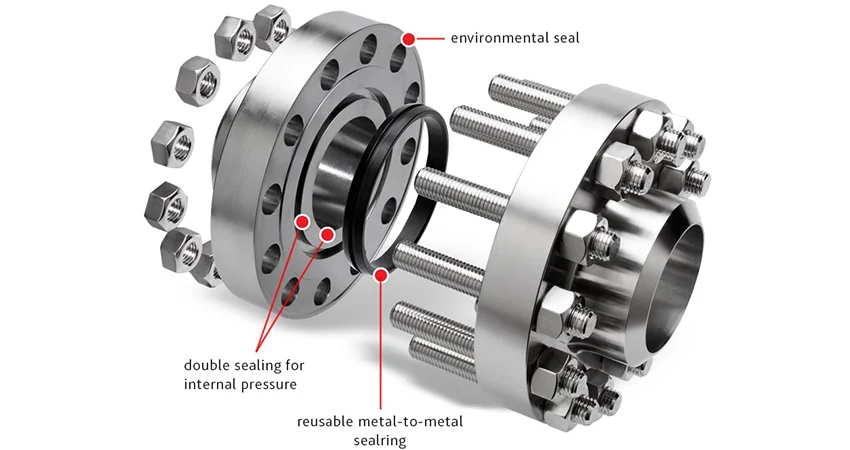

The flanges are made in multiple ways. Some have lips, while others do not. Nearly every type of flange has

a seal attached to it in order to preclude any type of leaks from the pipeline.

Large Diameter Flanges Types

Large Diameter Flanges are corrosion resistant and have a wide variety of uses. We carry variety of threaded

flanges, weld neck flanges and slip on flanges and of course we can can custom build Large Diameter Flanges

to your specifications.

The A350 LF2 Line is often referred to as Carbon Steel Low Temp Fittings or Flanges

Large Diameter Flanges Simple to fit

Large Diameter Flanges are an integral part of the pipeline system.

1 Simple to Fit

Simple installation in any weather and trench conditions,even underwater!

2 Long Life Expectancy

Elastomeric sealing gaskets are designed to have at least a 50 year lifespan

3 Corrosion Protection

Metal components are coated with Rilsan Nylon 11 which is WRAS approved for use with potable water. The nuts

and bolts are Sheraplex coated to WIS 4-52-03, offering long term protection against corrosion, impact and

abrasion to ensure continued reliable protection to corrosion, impact and abrasion and therefore ensures

continued reliable performance.

Bolting two different flanges together with a gasket place between the two flanges in order to make a seal in

the pipe joint creates flanged joints.

We carry a large inventory of Large Diameter Flanges in many types and sizes.

Federal

Check out the following information regarding Federal Large Diameter Flange products:

- Dimensional Tolerances

- Dimensions of Welding Ends

- Dimensions of Ring Joint Facings

- Series A/MSS SP44

- Series B/API 605 Flanges

Large Industry Standard Flanges

Large Industry Standard Flanges

Large industry standard flanges are vital connectors ensuring secure and

efficient operations in industrial piping systems.

Large industry standard flanges are critical components designed to connect pipes,

valves, pumps, and other equipment in industries like oil and gas,

chemical processing, power generation, and water treatment. Due to their

substantial size and scale, these flanges are typically made to order,

allowing customization to meet specific application requirements. Available in types such as

weld neck, slip-on, blind, and socket weld flanges, they are crafted from

durable materials like carbon steel, stainless steel, or alloys for

enhanced strength and corrosion resistance.

These industrial flanges connect pipes, valves, and other equipment, ensuring safe and

effective operations in multiple areas, and are typically made to order per application

given their size and scale.

Large industry standard flanges provide robust, standardized, and

customizable solutions for secure industrial piping connections.

Comparison of Large Diameter Flanges with Other Standards

| Standard/Type |

Material |

Size Range |

Pressure Rating |

Key Advantage |

| Large Diameter Flanges |

Carbon/Stainless Steel |

24”–120” |

Up to Class 2500 |

High Load-Bearing Capacity |

| ASME B16.5 |

Forged Steel |

1/2”–24” |

Class 150–2500 |

Standardized Versatility |

| MSS SP-44 |

Forged Steel |

NPS 12–60 |

Class 150–900 |

Heavy-Duty for Large Pipes |

| Weld Neck Flange |

Carbon Steel |

1/2”–48” |

Class 150–2500 |

Enhanced Weld Integrity |

Large Diameter Flanges excel in load-bearing, while ASME B16.5 offers

versatility, MSS SP-44 suits large pipes, and Weld Neck Flanges enhance

welding as of August 24, 2025.