Enhancing Fluid Flow In Piping Systems

In a long radius elbow, the centreline radius is 1.

Enhancing Fluid Flow In Piping Systems

In a long radius elbow, the centreline radius is 1.5 times the nominal size of the pipe or you can say 1.5 times the diameter of the pipe. Our seamless alloy steel LR elbows ensure durability in high-pressure industrial piping systems.

Long Radius Elbow fittings are essential for industrial piping systems, offering a smooth flow transition with a bending radius of 1.5 times the pipe diameter (R=1.5D). Engineered for corrosion resistance and erosion resistance, our seamless alloy steel LR elbows comply with ASME B16.9 standards, making them ideal for boiler pipeline protection in refineries, petrochemical plants, and power generation facilities.

Manufactured through hot-rolling or cold-drawing, these seamless alloy elbows undergo precise heat treatment to enhance mechanical properties. Their high chromium (4.00-6.00%) and molybdenum (0.45-0.65%) content ensures superior oxidation resistance, creep strength, and durability against abrasive materials, perfect for handling corrosive fluids, gases, and slurries in industrial piping. Available in angles like 90°, 45°, and 22.5°, LR elbows minimize pressure loss, making them suitable for high-pressure and high-flow systems.

Our long radius elbows support welding, bending, and flanging, with recommended preheating (150-200°C) and post-weld heat treatment (650-700°C) to ensure weld integrity. Available in sizes from 1/2” to 24” (DN15 to DN600) and wall thicknesses from SCH 40 to SCH 160, they meet diverse pipeline requirements. Rigorous testing, including tensile, flattening, and hydrostatic tests, ensures compliance with industry standards for temperatures up to 650°C.

Enhanced with coatings like 3LPE or FBE, these elbows provide exceptional corrosion resistance, ideal for oil and gas pipelines, chemical processing, and pneumatic conveying systems. Compared to short-radius elbows, LR elbows offer smoother flow and reduced wear, making them the preferred choice for boiler pipeline protection in high-throughput environments.

For engineers seeking reliable industrial piping solutions, our long radius elbows deliver unmatched strength, safety, and longevity, addressing challenges like pipeline wear, corrosion, and thermal stress.

| Feature | LR Alloy Elbow | SR Alloy Elbow | Stainless Steel Elbow |

|---|---|---|---|

| Material Type | Ferritic Alloy Steel | Ferritic Alloy Steel | Stainless Steel |

| Bending Radius | 1.5D | 1D | 1.5D or 1D |

| Temperature Range | High (up to 650°C) | High (up to 650°C) | High (up to 870°C) |

| Corrosion Resistance | Excellent (High Cr/Mo) | Excellent (High Cr/Mo) | Superior (Austenitic) |

| Erosion Resistance | Excellent | Good | Moderate |

| Applications | Boilers, Petrochemical, Refineries | Tight Spaces, Low Pressure | Food Processing, Marine |

| Pressure Loss | Low | High | Low to Moderate |

| Key Advantage | Smooth flow, high-temp corrosion resistance | Compact design | Superior corrosion resistance |

High chromium content ensures protection against rust and corrosive fluids.

Durable alloy steel withstands wear from abrasive slurries.

Ideal for high-temperature boiler systems and industrial applications.

Supports welding and bending for flexible pipeline configurations.

Long lifespan reduces maintenance and replacement costs.

1.5D radius ensures minimal pressure loss in high-flow systems.

A curated list of long-tail keywords for long-radius alloy elbows, covering specifications, applications, and material properties.

Note: ASME B16.9 covers long-radius alloy elbows for high-temperature and corrosion-resistant applications. Contact a certified supplier for detailed specifications.

Pipe fitting dimensions are in either metric or Standard English. Common fittings include 90° long radius, 45° elbows, and 180° return bends. LR and SR elbows are widely used in heating and cooling units.

Define requirements for design, fabrication, materials, tests, and inspection of piping systems.

Provide design and construction rules for pipe fittings, adapters, flanges, sleeves, elbows, tees, valves, etc.

| Carbon Steel | A234 WPB (A & C available) |

| High Yield Carbon | Enhanced strength properties |

| Stainless Steel | 304, 316 (SCH 10 common) |

| Nickel Alloys | Specialized applications |

| ASME B16.9 | Factory-Made Wrought Steel |

| ASME B16.28 | Short Radius Elbows |

| ASME B16.25 | Buttwelding Ends |

| MSS SP-97 | Welding End Standards |

Plain Bevel and Compound Bevel

All welded pipe fittings have beveled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases.

Welding Bevel acc. to

Butt weld pipe fitting bevels provide reliable, high-strength connections for demanding industrial piping applications.

|

DIN Standard German Industrial Standard |

EN Standard European Norm (CEN) |

ASME Standard American Society of Mechanical Engineers |

|---|---|---|

Low-Carbon & Low-Temp Steel

|

Low-Carbon & Low-Temp Steel

|

Low-Carbon & Low-Temp Steel

|

Low-Alloy High-Strength Steel

|

Low-Alloy High-Strength Steel

|

Low-Alloy High-Strength Steel

|

Molybdenum Steel (High-Temp)

|

Molybdenum Steel (High-Temp)

|

Molybdenum Steel (High-Temp)

|

Cr-Mo Steel (Medium Cr Content)

|

Cr-Mo Steel (Medium Cr Content)

|

Cr-Mo Steel (Medium Cr Content)

|

High Cr-Mo-V Steel (Super High-Temp)

|

High Cr-Mo-V Steel (Super High-Temp)

|

High Cr-Mo-V Steel (Super High-Temp)

|

Industries Using

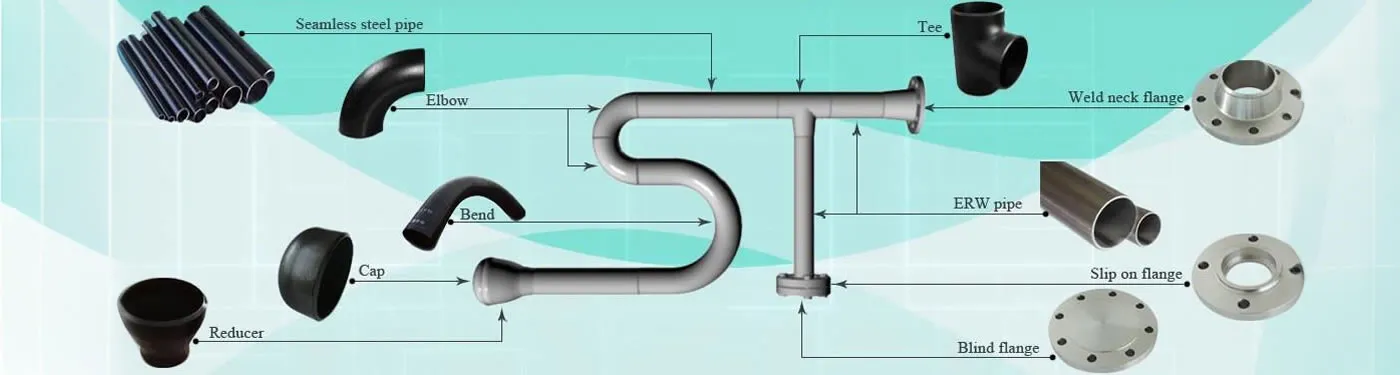

Long Radius Elbow components that are used to connect, join, or adapt different parts of a system, such as pipes, tubes, or hoses. They serve multiple purposes, including:

The choice of fittings depends on the specific requirements of the system, including factors like the type of fluid or gas, pressure, temperature, and the layout of the piping or tubing system.

Astm a192 carbon steel elbows are specialized pipe...

Discover short-radius elbows designed for corrosio...

A Reducer Elbow is a fitting used to join two diff...

Explore our high-quality astm a420 wpl6 elbows des...

Explore astm a234 wp22 elbows designed for corrosi...

Asme sa335 p91 elbows are premium alloy steel pipe...