Pipe Bends

Precision Flow Direction Solutions

Pipe bends are curved piping components used to change the direction of fluid flow in pipelines, offering smooth transitions and reduced pressure drop for various industrial applications.

Precision Flow Direction Solutions

Pipe bends are curved piping components used to change the direction of fluid flow in pipelines, offering smooth transitions and reduced pressure drop for various industrial applications.

Reduced pressure drop and friction

Tailored to specific requirements

3D, 5D, 8D, 10D bend options

Advanced bending technology

A pipe bend is a curved section of pipe used to change the direction of fluid flow in a piping system, offering smoother flow transitions compared to standard elbows.

Custom-made curved sections with larger radii (3D, 5D, 10D) providing smoother flow paths than standard elbows.

Larger radius bends minimize frictional resistance and pressure loss, improving system efficiency.

Pipe Bends are high-quality pipe fittings designed for industrial piping systems, offering smooth flow transitions and compliance with ASME B16.9 or MSS SP-43 standards. Available in materials like carbon steel (ASTM A234 WPB) and stainless steel (ASTM A403 WP304/WP316), these bends provide excellent strength, erosion resistance, and corrosion resistance, making them ideal for boiler pipeline protection in industries such as oil and gas, power generation, and chemical processing.

Pipe bends are manufactured through hot-forming (hot induction bending) or cold-forming processes, ensuring durability across a wide temperature range (up to 870°C for stainless steel, 425°C for carbon steel). With larger bend radii (e.g., 3D, 5D, or 10D), they reduce turbulence and pressure loss compared to standard elbows. Available in angles of 90°, 45°, 30°, or custom configurations, pipe bends support seamless or welded designs for versatile industrial piping applications.

These bends support welding, bending, and flanging, with material-specific weldability (excellent for WP304/WP316, good for WPB). Available in sizes from 1/2” to 48” (DN15 to DN1200) and wall thicknesses from SCH 10 to SCH 160, they meet diverse pipeline requirements. Rigorous testing, including tensile, flattening, and radiographic inspections, ensures compliance with industry standards for reliable performance.

Pipe bends can be coated (e.g., FBE, 3LPE, galvanizing for carbon steel; passivation for stainless steel) to enhance corrosion resistance, protecting against rust and chemical attack. Their smooth flow characteristics and material options make them ideal for boiler pipeline protection in demanding environments, balancing cost, strength, and corrosion resistance.

For engineers seeking efficient and durable industrial piping solutions, pipe bends deliver smooth flow, reduced wear, and reliable performance, addressing challenges like pipeline corrosion, mechanical stress, and high-temperature demands.

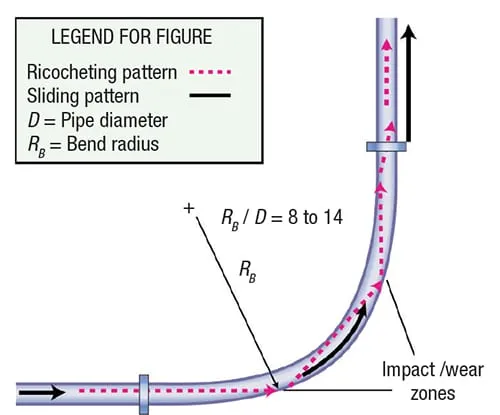

Pipe bends can take a variety of different geometries, which can have a significant influence on particle impact angle. Basic long-radius bends are the most commonly used because they provide the most gradual change in direction for solids, and because the angle of impact on the pipe wall is relatively small, which helps to minimize the risk of attrition or erosion.

Common-radius bends are made by bending standard tubes or pipes (Figure). The radius of curvature, RB, may range from 1 to 24 times the tube diameter, D. Common-radius bends can be loosely classified as follows: Elbow (RB /D = 1 to 2.5); Short radius RB /D = 3 to 7; Long-radius (RB /D = 8 to 14; Long sweep (RB /D = 15 to 24).

Figure. Flow in a standard, long-radius bend is illustrated here, with typical flow patterns,

wear points and reacceleration zone shown

Figure. Flow in a standard, long-radius bend is illustrated here, with typical flow patterns,

wear points and reacceleration zone shown

A fitting bend is a type of piping fitting that is used to change the direction of a piping system. It is commonly used in plumbing, HVAC, and industrial applications where a change in the direction of flow or the orientation of the pipe is required.

Fitting bends are available in different angles, such as 45 degrees, 90 degrees, and 180 degrees, to accommodate various piping configurations. They can be made from different materials, such as carbon steel and stainless steel, depending on the application.

Fitting bends are designed to provide a smooth and gradual change in the direction of the pipe, which helps to reduce turbulence and pressure drop in the system. They are also available in different styles, such as long radius bends, short radius bends, and standard bends, which allow for greater flexibility and customization in piping system design.

The installation of fitting bends requires careful consideration of the pipe size, material, pressure, temperature, and fluid being conveyed to ensure proper fit and performance. In some cases, a combination of fitting bends, tees, and other fittings may be required to achieve the desired piping configuration.

High-frequency induced electrical power heats pipe to 850-1100°C for precise bending.

Hydraulically driven ram forces pipe against pivot blocks or rollers.

Rolls positioned vertically or horizontally to produce very large radii bends.

Internal mandrel support ensures minimal deformation and consistent diameter.

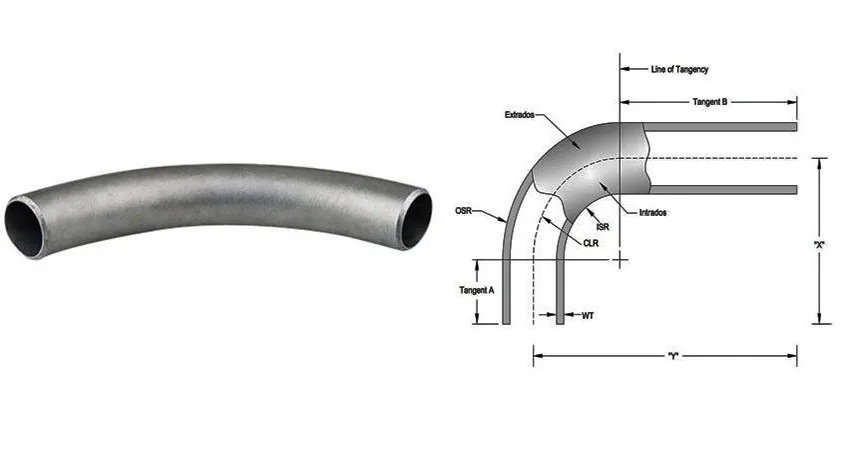

The radius of the pipe's centerline through the bend

The external diameter of the pipe being bent

The thickness of the pipe wall, critical for bend quality

Pipes experience spring back after bending. Harder pipes and smaller centerline radii result in more spring back, which causes radial growth. Proper calculation and compensation are essential for achieving the perfect bend.

A curated list of long-tail keywords for pipe bends, covering diverse bending applications, specifications, and material properties.

Note: Pipe bends are designed for smooth flow and corrosion-resistant industrial piping across various applications. Contact a certified supplier for detailed specifications.

Radius is three times the nominal diameter. Compact design for space-limited applications.

Radius is five times the nominal diameter. Optimal balance of flow and space requirements.

Radius is ten times the nominal diameter. Maximum flow efficiency with minimal pressure drop.

For a 10-inch diameter pipe with a 5D bend:

Centerline Radius = 5 × 10 inches = 50 inches

The radius calculation helps determine the space requirements and flow characteristics of the bend.

| Material Type | Grades & Standards |

|---|---|

| Stainless Steel | ASTM A403 WP Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Carbon Steel | ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 |

| Low-Temperature Carbon Steel | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex & Super Duplex Steel | ASTM A815, ASME SA 815 UNS 31803, UNS 32205 (Dual Certified) |

The Pipe Bends are used in the following industries:

End cap, also known as pipe cap, are pipe fittings...

Pipe elbow offers a durable, corrosion-resistant s...

A weldolet is a type of pipe fitting used for bran...

A pipe reducer is a fitting used in piping systems...

A pipe tee is also called triplet,three way and 't...

A stub end is a pipe fitting designed to be welded...