Seamless And Welded High-pressure Pipe Bends For Robust Pipeline Systems

High-pressure pipe bending solutions, crafted from carbon and stainless steel, designed for corrosion-resistant industrial piping in oil and gas, power generation, and high-pressure applications.

Seamless And Welded High-pressure Pipe Bends For Robust Pipeline Systems

High-pressure pipe bending solutions, crafted from carbon and stainless steel, designed for corrosion-resistant industrial piping in oil and gas, power generation, and high-pressure applications.

High-Pressure Pipe Bends are specialized pipe fittings designed for industrial piping systems operating under high-pressure conditions, compliant with standards like ASME B16.9 and MSS SP-43. Crafted from carbon steel (ASTM A234 WPB) or stainless steel (ASTM A403 WP304/WP316), these bends offer exceptional strength, erosion resistance, and corrosion resistance, making them ideal for boiler pipeline protection in industries such as oil and gas, power generation, chemical processing, and automotive applications.

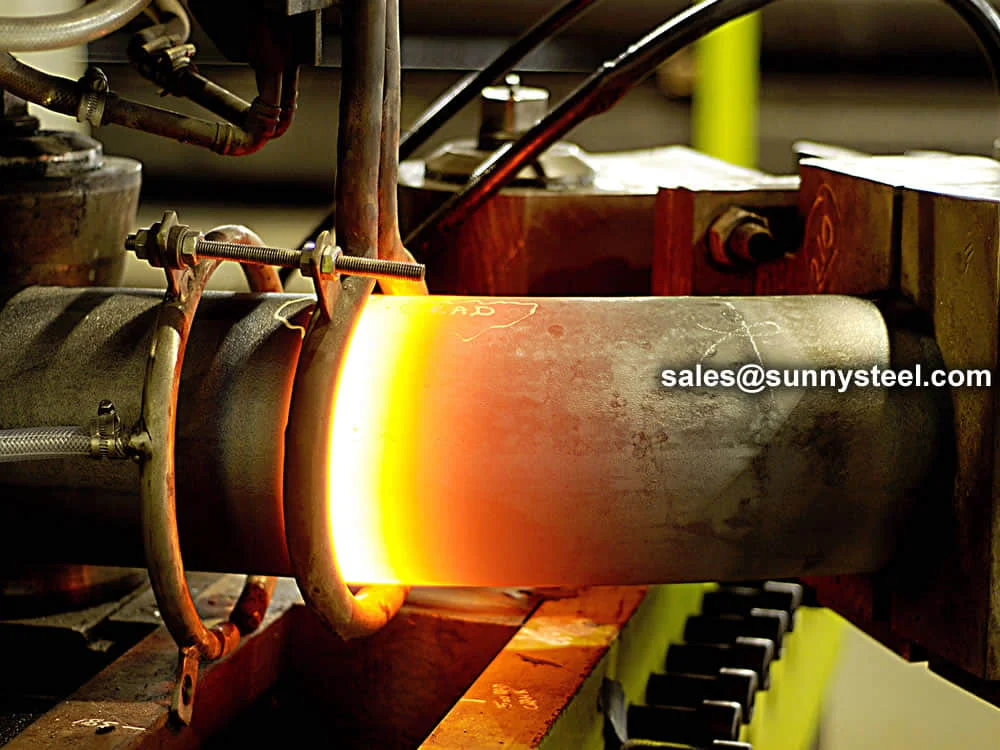

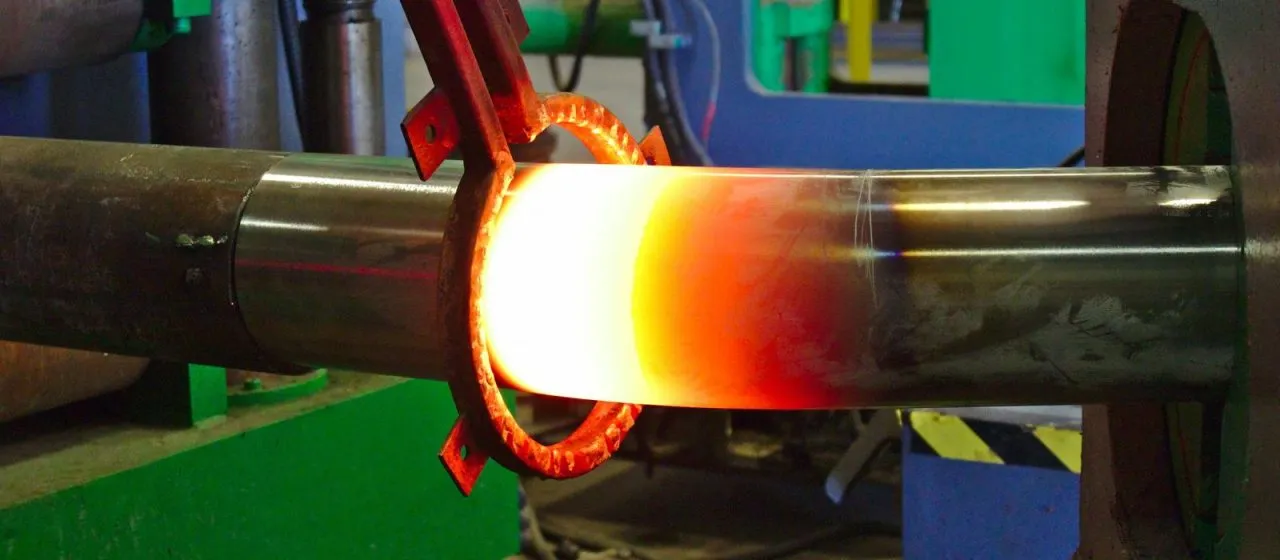

Manufactured through hot induction bending or cold-forming, high-pressure pipe bends feature bend radii like 3D, 5D, or 10D, ensuring smooth flow transitions and minimal pressure loss compared to standard elbows. Available in angles of 90°, 45°, 30°, or custom configurations, and in sizes from 1/2” to 48” (DN15 to DN1200) with wall thicknesses from SCH 40 to SCH 160 or XXS, these bends are built to withstand extreme pressures and temperatures (up to 870°C for stainless steel, 425°C for carbon steel).

High-pressure pipe bends support welding, bending, and flanging, with excellent weldability for stainless steel and good weldability for carbon steel. Rigorous testing, including chemical analysis, tensile testing (≥370 N/mm² for carbon steel, ≥515 N/mm² for stainless steel), flattening, and nondestructive examinations (radiographic, ultrasonic, or eddy current), ensures compliance with industry standards for high-pressure applications.

Coated with galvanizing, FBE, or 3LPE for carbon steel, and passivation for stainless steel, high-pressure pipe bends enhance corrosion resistance, protecting against rust and chemical exposure in demanding environments. Their smooth interior surfaces minimize flow resistance, making them suitable for boiler pipeline protection, refinery piping, and high-pressure automotive systems like exhausts and roll cages.

For engineers seeking reliable and durable industrial piping solutions, high-pressure pipe bends deliver smooth flow, high strength, and performance, addressing challenges like pipeline corrosion, mechanical stress, and high-pressure demands in critical applications.

A High pressure pipe bending is a pipe bend that used in high pressure application. Our induction pipe bending services are ideal for the the general and process pipework industries, offshore oil and gas production sectors and the power generation. We provide an exceptional range of post-bend heat treatment solutions.

Additionally, hydraulic pipe benders are available to bend metal pipes to specific angles using hydraulic pressure, suitable for bending tasks involving different types of metal pipes.

Apart from high-pressure pipe bending technology, there are other related techniques, such as cold bending methods, which do not require heating the metal pipe and can be done directly at room temperature [6]. Furthermore, there are different machines designed for bending various types of pipes, such as manual pipe benders and rotary draw bending machines.

Regardless of the bending technique employed, it is important to note that the bending radius during high-pressure pipe bending should be at least six times the diameter of the pipe to ensure the quality of the bending process.

High-pressure pipe bending technology finds extensive application in the industrial and manufacturing sectors. These techniques allow pipes to adapt to various scenarios with complex layouts and special requirements. Inductive pipe bending services ensure the performance and quality of the metal material during the bending process, making it suitable for high-pressure applications. Hydraulic pipe benders provide efficient and precise solutions for large-scale production while catering to the customization needs of different pipes.

For engineering design and pipe construction, selecting the appropriate pipe bending technology is crucial. Properly choosing the bending radius and avoiding excessive bending can prolong the lifespan of the pipes and reduce the risk of potential leaks and failures. Therefore, when using high-pressure pipe bending technology, strict adherence to relevant regulations and standards is essential to ensure the safe operation of the pipe system.

In conclusion, high-pressure pipe bending technology holds promising applications in the industrial sector and is suitable for various high-pressure pipe systems. However, careful handling is necessary during its usage to ensure safety and reliability.

High-pressure pipe bending is a specialized process that involves the manipulation of pipes to achieve precise bends while maintaining structural integrity and efficient flow. This technique is crucial in various industries, including oil and gas, petrochemicals, power generation, aerospace, and more. At Sunny Steel, we excel in high-pressure pipe bending, leveraging advanced technologies and skilled craftsmanship to meet the most challenging project requirements.

As industry leaders, we pride ourselves on offering exceptional services and achieving unmatched customer satisfaction. Our dedication to providing top-quality high-pressure pipe bending solutions has earned us a reputation for excellence in the market.

At Sunny Steel, we redefine high-pressure pipe bending with our precision engineering and commitment to delivering excellence. With our experienced team, cutting-edge technology, and client-focused approach, we aim to exceed expectations in every project we undertake.

| Specification | Details |

|---|---|

| Standards | ASME B16.9, MSS SP-43 |

| Materials | Carbon Steel (ASTM A234 WPB), Stainless Steel (ASTM A403 WP304/WP316) |

| Sizes | 1/2” to 48” (DN15 to DN1200) |

| Wall Thickness | SCH 40 to SCH 160, XXS |

| Bend Radii | 3D, 5D, 10D, or Custom |

| Angles | 90°, 45°, 30°, or Custom |

| Manufacturing | Hot Induction Bending, Cold-Forming, Seamless, Welded |

| Coatings | FBE, 3LPE, Galvanizing (Carbon Steel), Passivation (Stainless Steel) |

| Testing | Chemical Analysis, Tensile, Flattening, Radiographic, Ultrasonic, Hydrostatic |

| Feature | High-Pressure Pipe Bends | High-Pressure Elbows (ASME B16.9) |

|---|---|---|

| Bend Radius | 3D, 5D, 10D, or Custom | 1D (SR), 1.5D (LR) |

| Flow Characteristics | Smooth, low turbulence | Higher turbulence |

| Size Range | 1/2” to 48” (DN15 to DN1200) | 1/2” to 24” (DN15 to DN600) |

| Applications | High-pressure pipelines, refineries, automotive | Compact high-pressure systems |

| Corrosion Resistance | Enhanced by coatings/passivation | Enhanced by coatings/passivation |

| Key Advantage | Reduced pressure loss, smoother flow | Compact, cost-effective for tight spaces |

Our seasoned professionals bring extensive experience and attention to detail, ensuring flawless execution and exceptional results.

We invest in cutting-edge equipment and advanced machinery to deliver precise, efficient, and reliable pipe bending across all sizes and materials.

Every project is unique. We provide customized solutions designed to meet specific requirements, working closely with clients to deliver exact results.

From material selection to final bend, we follow strict quality standards to ensure each pipe bend meets industry regulations and client expectations.

Our efficient workflow and streamlined processes ensure projects are delivered on time—without compromising on quality.

We begin by analyzing project requirements and specifications to design a plan that ensures optimal results.

Together with clients, we select the most suitable pipe material based on temperature, pressure, and corrosion resistance.

Using state-of-the-art bending equipment, we execute precise bends with high accuracy, meeting international standards.

Every bend undergoes rigorous inspections to confirm dimensional accuracy, integrity, and compliance with project requirements.

Finished bends are carefully packaged and delivered safely to the client’s location, ready for installation.

A curated list of long-tail keywords for high-pressure pipe bends, covering diverse bending applications, specifications, and material properties.

Note: High-pressure pipe bends are designed for smooth flow and corrosion-resistant industrial piping across various high-pressure applications. Contact a certified supplier for detailed specifications.

Radius is three times the nominal diameter. Compact design for space-limited applications.

Radius is five times the nominal diameter. Optimal balance of flow and space requirements.

Radius is ten times the nominal diameter. Maximum flow efficiency with minimal pressure drop.

For a 10-inch diameter pipe with a 5D bend:

Centerline Radius = 5 × 10 inches = 50 inches

The radius calculation helps determine the space requirements and flow characteristics of the bend.

| Material Type | Grades & Standards |

|---|---|

| Stainless Steel | ASTM A403 WP Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Carbon Steel | ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 |

| Low-Temperature Carbon Steel | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex & Super Duplex Steel | ASTM A815, ASME SA 815 UNS 31803, UNS 32205 (Dual Certified) |

The High-Pressure Pipe Bending are used in the following industries:

A 7d pipe bending is a pipe bend that the bend rad...

15crmog pipe bending involves shaping seamless all...

12cr1movg pipe bending refers to the process of sh...

Astm a210 grade c pipe bending involves forming se...

Bending astm a213 t91 requires special care and te...

Large size pipe bending refers to the technique of...