Durable Butt-weld Fittings For Boiler Pipeline Durability

A lateral pipe tee means a pipe fitting which is similar to a tee but has a side opening outlet branch at a 45 degree angle.

Durable Butt-weld Fittings For Boiler Pipeline Durability

A lateral pipe tee means a pipe fitting which is similar to a tee but has a side opening outlet branch at a 45 degree angle.

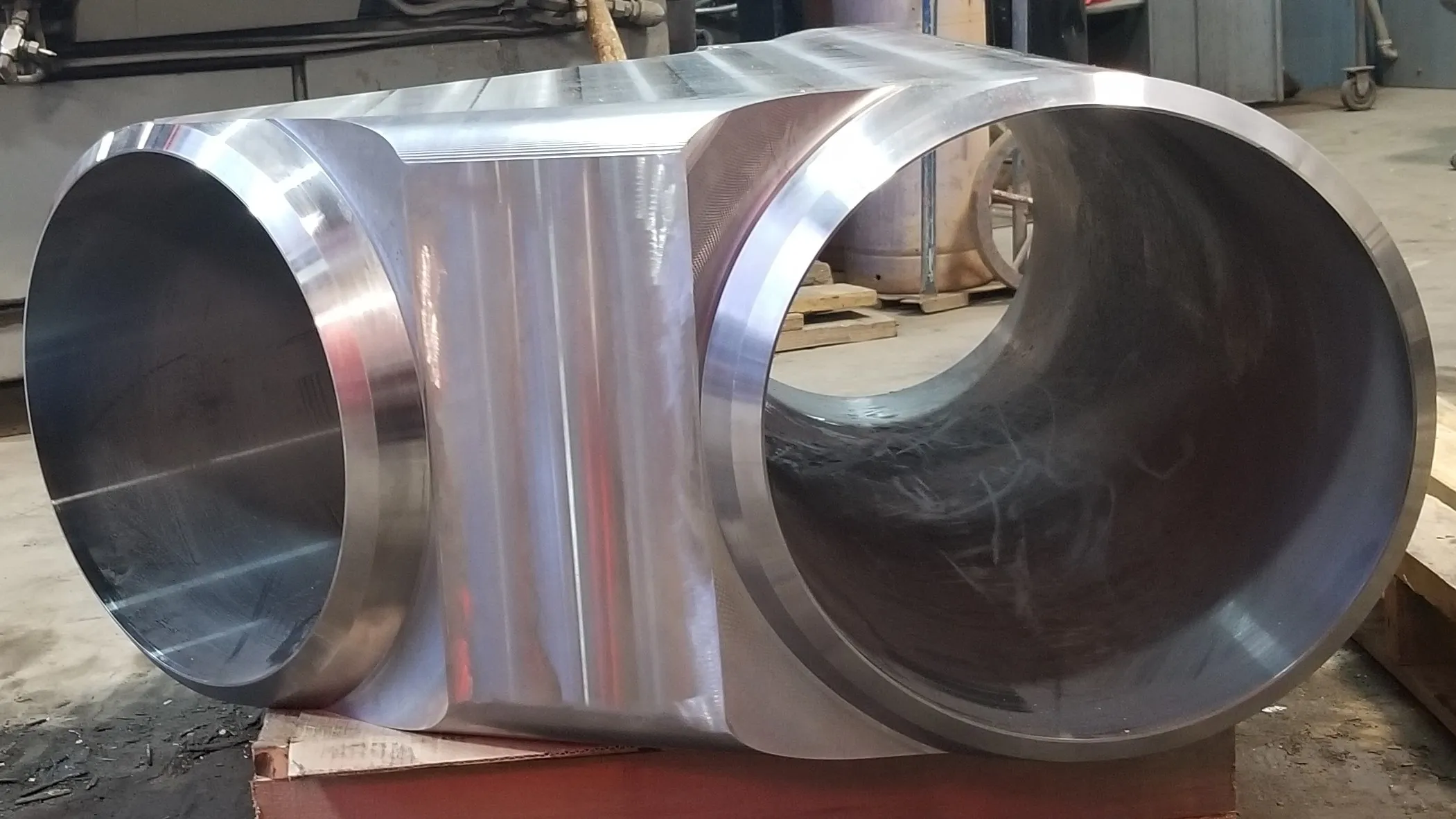

Lateral Tee is a T-shaped pipe fitting designed for industrial piping systems, connecting three pipes with the branch extending at a 45-degree angle from the main run, optimizing flow diversion. Compliant with ASTM A234 WPB standards, this carbon steel fitting provides robust pipeline corrosion protection and durability, making it ideal for boiler pipeline protection in oil and gas, petrochemical, and power generation industries as of 11:51 PM PDT, August 31, 2025. Its butt-weld design ensures leak-proof, high-strength connections for demanding applications.

The Lateral Tee is manufactured using seamless or welded processes, utilizing high-quality materials like ASTM A234 WPB (carbon steel) for general-purpose applications or ASTM A234 WP22 (low-alloy steel) for high-temperature environments. Available in sizes from 1/2” to 48” (DN 15–DN 1200) for the main run, with equal or reducing branch sizes, and wall thicknesses such as SCH 40, SCH 80, or XXS, it meets diverse industrial piping needs. Rigorous testing, including tensile, hydrostatic, and non-destructive tests (radiography or ultrasonic), ensures compliance with ASME B16.9 and MSS SP-75 standards.

Engineered for pipeline corrosion protection, the Lateral Tee can be coated with epoxy, galvanizing, or 3LPE to withstand harsh environments, such as offshore pipelines or chemical processing plants. Its robust construction resists wear from abrasive materials and high-pressure conditions, ensuring reliability for boiler pipeline protection. The fitting supports welding methods (SMAW, GTAW, or GMAW) with low-carbon fillers, ensuring compatibility with pipelines like ASTM A106 Gr.B or API 5L Gr.B, facilitating seamless integration into complex systems.

Unlike Equal Tee or Reducing Tee fittings (90-degree branches, as discussed in your previous queries) or Piggable Tee fittings (with internal bars for pigging), the Lateral Tee offers a 45-degree branch for smoother flow transitions and reduced turbulence in industrial piping systems. For highly corrosive environments, stainless steel options like ASTM A403 TP347H provide superior corrosion resistance, while WPB offers a cost-effective solution for moderate conditions. Its versatility makes it suitable for oil and gas pipelines, petrochemical plants, power generation systems, and water treatment applications.

The Lateral Tee addresses critical challenges like pipeline wear, corrosion, and flow efficiency in high-throughput industrial systems. Its durable design and material options ensure long-term performance, safety, and efficiency, making it a top choice for engineers seeking robust industrial piping and boiler pipeline protection solutions.

A lateral tee is a specialized type of pipe fitting that features a T-shaped design, with an additional outlet at a 90-degree angle from the main pipeline. This unique configuration allows for the diversion of fluid flow from the main line to the lateral line, enabling efficient distribution to various destinations.

A lateral tee is a type of pipe fitting that is used to connect a branch line at right angles to a pipeline. It has a straight section of pipe, known as the "run," with a branch off of it at a 90-degree angle, called the "lateral." The lateral can be equal or unequal in size compared to the run.

Lateral tees are commonly used in piping systems where a new branch line needs to be added perpendicular to an existing pipeline. They are available in different materials such as carbon steel, stainless steel, alloy steel, and other metals, depending on the application.

There are two types of lateral tees: equal lateral tee and reducing lateral tee.

An equal lateral tee has branches of the same size, which means that the fluid flowing through the pipeline will be divided equally into the branch line.

A reducing lateral tee, on the other hand, has a smaller branch than the main pipeline. It is used when the flow rates in the branch line need to be reduced compared to the main pipeline.

When incorporating lateral tees into fluid systems, certain considerations are essential:

Material Selection: Choose materials that are compatible with the fluid being transported to prevent corrosion or contamination.

Orientation: Proper orientation of the lateral tee is crucial to ensure effective fluid diversion and distribution.

The lateral tee stands as a critical component in fluid control systems, offering the capability to direct and distribute fluids efficiently to various destinations. Its versatile design, advantageous features, and wide-ranging applications make it indispensable across industries. Whether in industrial processes, plumbing systems, or agricultural setups, the lateral tee plays a vital role in ensuring the smooth and controlled flow of fluids, enhancing overall system performance and reliability.

ANSI B16.9 Lateral Tee

ANSI B16.9 Flanged Lateral Tee

ANSI B16.9 Reducing Lateral Tee

| Feature | ASME/ANSI B16.9 Lateral Tee | ASME/ANSI B16.9 Equal Tee | ASME/ANSI B16.9 Reducing Tee |

|---|---|---|---|

| Material | Carbon Steel (A234 WPB), Stainless Steel (304, 316L), Alloy Steel (WP11, WP22) | Carbon Steel (A234 WPB), Stainless Steel (304, 316L), Alloy Steel (WP11, WP22) | Carbon Steel (A234 WPB), Stainless Steel (304, 316L), Alloy Steel (WP11, WP22) |

| Standard | ASME/ANSI B16.9, ASTM A234, ASTM A403 | ASME/ANSI B16.9, ASTM A234, ASTM A403 | ASME/ANSI B16.9, ASTM A234, ASTM A403 |

| Branch Angle | 45-degree | 90-degree | 90-degree |

| Function | Angled branching for smooth flow | Uniform branching (equal diameters) | Branching with reduced diameter |

| Corrosion Resistance | Excellent (stainless steel, FBE-coated carbon steel) | Excellent (stainless steel, FBE-coated carbon steel) | Excellent (stainless steel, FBE-coated carbon steel) |

| Erosion Resistance | Excellent (reduced turbulence) | Good (uniform flow applications) | Good (flow applications) |

| Applications | Oil/Gas, Chemical, Power Generation | Oil/Gas, Petrochemical, Boilers | Oil/Gas, Petrochemical, Boilers |

| Temperature Range | Up to 450°C (carbon steel), 870°C (stainless steel) | Up to 450°C (carbon steel), 870°C (stainless steel) | Up to 450°C (carbon steel), 870°C (stainless steel) |

| Key Advantage | Smooth 45-degree flow transition | Balanced flow distribution | Adapts to varying pipe sizes |

A curated list of long-tail keywords for ASME/ANSI B16.9 lateral tees, covering specifications, applications, and material properties, presented in a two-column layout.

Note: ASME/ANSI B16.9 lateral tees are designed for smooth 45-degree branching and corrosion resistance. For detailed specifications, refer to ASME B16.9, ASTM A234, or contact a certified supplier.

Allows for efficient splitting or combining of fluid flows in complex piping layouts.

Designed to maintain the strength and integrity of the piping system.

Available to suit various pipe diameters, pressure ratings, and fluid compatibility.

Smooth internal contours minimize turbulence and pressure loss.

Different connection types offer flexibility in installation.

Manufactured from high-quality materials for long service life.

Description: All three openings are equal in diameter.

Description: One opening is smaller than the others.

Description: Internal bars to prevent pig entry.

Description: Branch connection at an angle (e.g., 45°).

Description: Curved branch for clean-out plug.

Description: Four equal-sized female openings.

| Material Type | Standards & Grades | Characteristics | Applications |

|---|---|---|---|

| Carbon Steel | ASTM A234 WPB, A420 WPL6, A105 | High strength, cost-effective, good weldability | General industrial piping, oil & gas, power generation |

| Stainless Steel | ASTM A403 WP304/304L, WP316/316L, WP321, WP347 | Excellent corrosion resistance, hygienic properties | Chemical processing, food & beverage, pharmaceutical |

| Alloy Steel | ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 | Enhanced strength, high-temperature resistance | High-temperature and high-pressure services |

Robust & Economical

Corrosion Resistant

High Performance

Install pipe tee

The basic application of the Lateral Tee is a connector that can be used in the middle of two pipes to allow them to join together.

Understanding the various pipe tee types allows engineers and contractors to make more informed decisions based on flow requirements, space limits, and material compatibility. Newzel Industries offers a diverse range of pipe tees in several grades, including SS 304, 316, and 321, all fabricated with accuracy to meet your industrial requirements. Contact us today for an estimate or technical assistance in determining the optimal pipe tee type for your project.

Y tees ensure corrosion-resistant, smooth fluid fl...

Split tees provide robust, corrosion-resistant bra...

Large diameter elbows provide durable, corrosion-r...

Stainless steel tees are butt-weld pipe fittings d...

Reducing tee, like all pipe tees, is in the shape ...

The equal tee (equivalent tee or straight tee) is ...