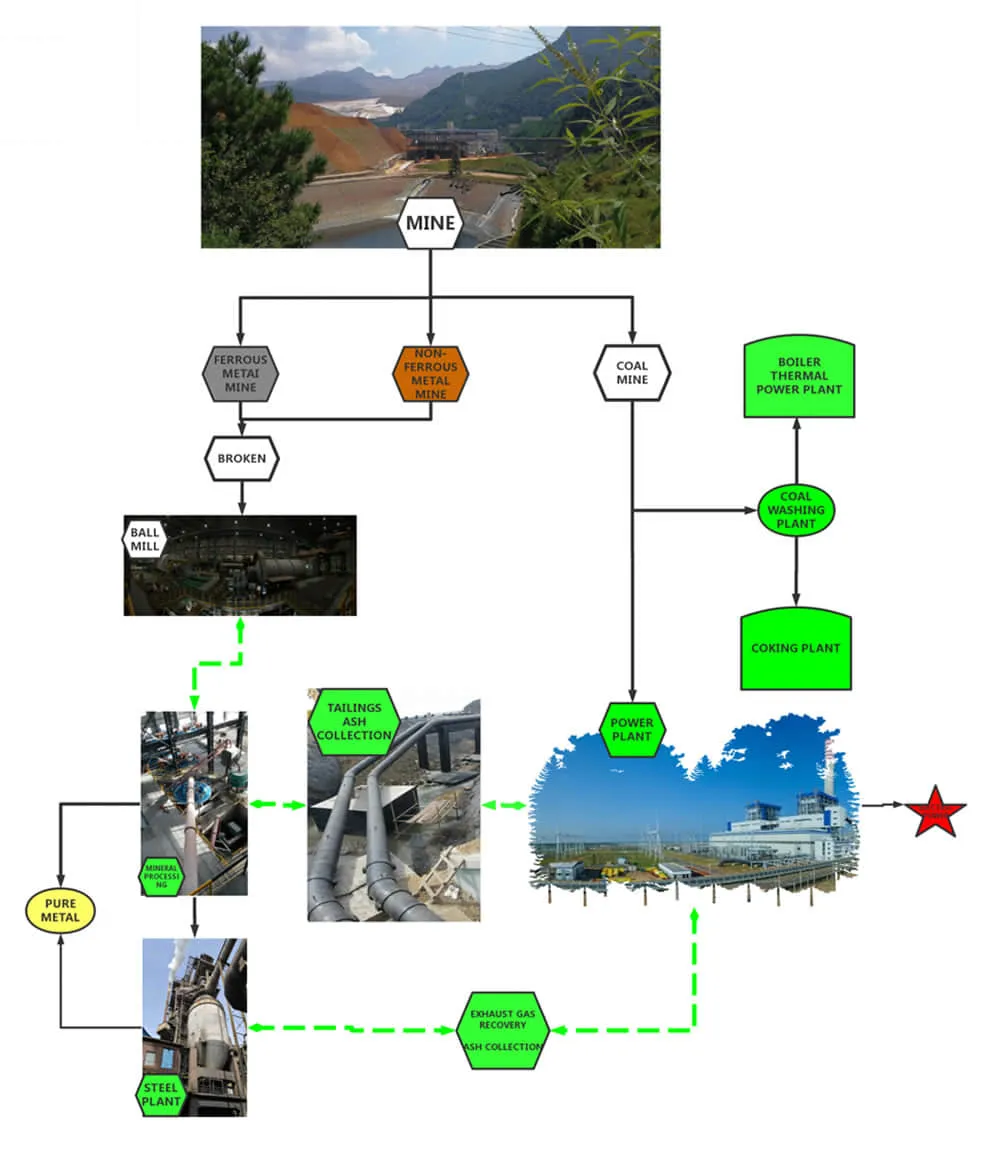

High-performance Power Generation Systems

Superior cast basalt composite pipes deliver exceptional wear resistance and corrosion protection for power plant ash handling systems.

High-performance Power Generation Systems

Superior cast basalt composite pipes deliver exceptional wear resistance and corrosion protection for power plant ash handling systems.

| Cast Basalt Pipe DN (mm) |

Standard Steel Pipe OD (mm) |

Cast Basalt Thickness (mm) |

Length (mm) |

|---|---|---|---|

| 80 | 159 | 25 | 4000 |

| 100 | 168 | 17.5 20 |

4000 6000 8000 |

| 125 | 195 | ||

| 150 | 219 | ||

| 175 | 245 | 6000 8000 10000 12000 |

|

| 200 | 273 | ||

| 225 | 300 | ||

| 250 | 325 | ||

| 275 | 345 | ||

| 300 | 377 | ||

| 350 | 426 | ||

| 400 | 478 | 20 25 |

|

| 450 | 529 | ||

| 500 | 600 | 25 | |

| 550 | 650 | ||

| 600 | 720 | 30 | 6000 |

| 650 | 770 | ||

| 700 | 820 | ||

| 750 | 870 | ||

| 800 | 920 |

Other specifications of cast steel pipe lined with basalt can be manufactured according to customer technical requirements. Suitable for large-diameter basalt lining steel pipes with a nominal diameter greater than 800mm. Generally, according to the running status of the pipeline, different cement is used to fix the basalt brick inside the finished steel pipe to complete the basalt lining steel pipe. Its advantages are good wear resistance, wide range of use, basically not limited by the size of the pipeline and low cost of pipeline installation.

Cast basalt is a volcanic mineral material known for its exceptional abrasion resistance, complete impermeability to moisture, high compressive strength, and resistance to most acids and alkalis. It is entirely corrosion-proof, making it ideal for harsh industrial environments.

It is produced by melting selected natural basalt, crushed into 20–50 mm fragments, in shaft furnaces at approximately 1,300°C. The molten basalt is then cast and crystallizes into a uniform phaneritic structure, resulting in excellent hardness and wear resistance.

Cast basalt has a minimum hardness of 8 on the Mohs scale (diamonds are rated 10), making it extremely effective for abrasion and erosion protection.

Like other ceramics, it is sensitive to impact. Under normal service conditions, cast basalt withstands temperatures from -40°C to +350°C, but it should not be subjected to thermal shock.

Sizes: Cast basalt products come in the form of tiles, formed pieces, and segments. Straight pipes are spun-cast with nominal bores from 32 to 600 mm, wall thickness 20–30 mm, and standard lengths of 500 mm. Smaller bores, pipe segments with radii of 40–3000 mm, and special formed pieces are usually sand-cast. Steel molds can be used for higher volumes, producing 30–40 mm thick linings.

Cast basalt-lined pipes are widely used in abrasive and ash handling systems such as chutes, troughs, funnels, silos, dust collectors, rotary flow machines, conveyors, and feeders. In chemical plants, they can be used to line pickling tanks or store corrosive substances.

Customized specifications and shapes are available to meet specific project requirements.

Refined into a finely crystallized glass ceramic, Sunny Steel’s cast basalt linings offer extremely durable protection for static plants handling large volumes of abrasive or corrosive media.

Available in both pipe and tile form, cast basalt is ideal for wet material handling systems with lower impacts, such as coal chutes, ash sluiceways, and pipelines at power stations. It provides excellent resistance to wear, corrosion, and temperatures up to ~400°C.

Our factory is equipped with professional technical research and design personnel who can provide product optimization design and services.

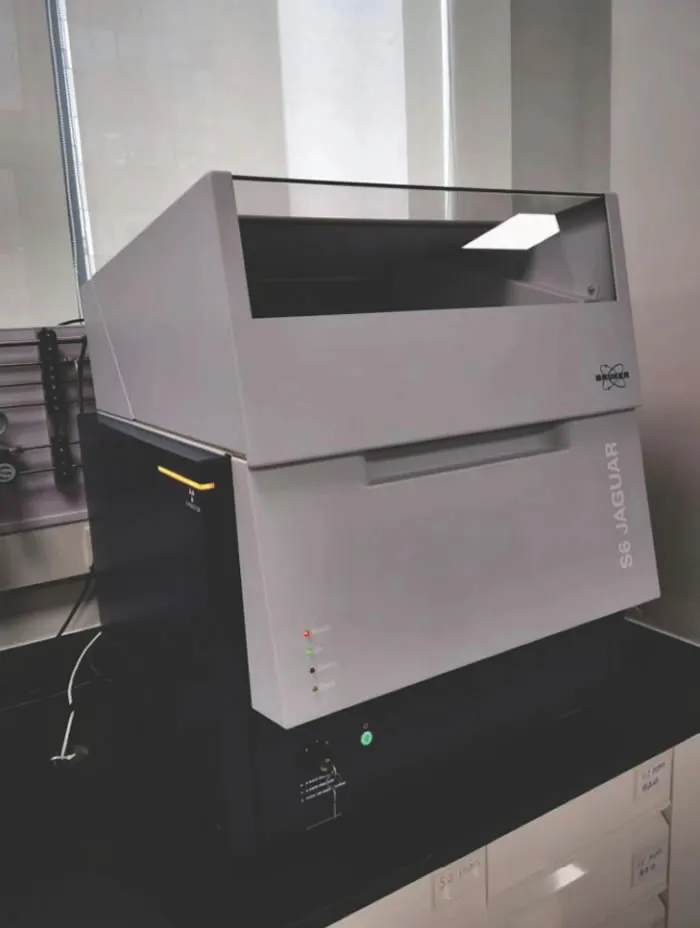

S6 JAGUAR Wavelength Dispersive X-ray Fluorescence Spectrometer

Pendulum Friction Coefficient Tester

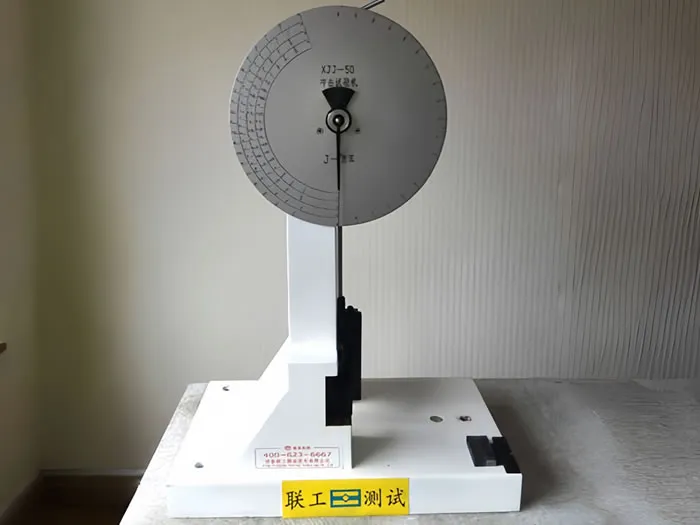

XJJ-50 Single Beam Impact Testing Machine

HV-5 Vickers Hardness Tester

CMT-100 Microcomputer Controlled Electronic Universal Testing Machine

MSY-A Friction and Wear Testing Machine

Manufacturing Process

Manufacturing Process

Cast basalt is a silicate crystalline material manufactured through a high-temperature refining process. It is produced using natural igneous rocks such as basalt, diabase, or selected industrial waste slag as the primary raw material.

These materials undergo melting, casting, controlled crystallization, and annealing, resulting in a dense, highly wear- and corrosion-resistant product.

A cast basalt lined pipe typically consists of three layers:

Cast basalt ceramic for abrasion and corrosion resistance

Steel pipe for structural strength

Cement mortar for bonding and chemical passivation

Composite Benefits: This composite structure ensures high durability, pressure resistance, and corrosion protection.

The cement mortar creates an alkaline environment on the inner steel surface, forming a passive protective film that prevents corrosion. Overall, the cast basalt lined pipe is ideal for transporting abrasive or corrosive media in complex operating conditions.

Elbows are designed with turning radii and center angles based on user requirements and share the same diameter series as straight pipes.

Cast basalt can be used for the lining of pipework, chutes, bunkers, cyclones, and hoppers.

It has become the global standard in areas such as ash slurry pipework, often used at fossil-fuel power stations. It is an all-round cost-effective and adaptable lining material that extends the life of equipment in pipe or tile form where affected by erosion.

Cast basalt is well-proven in a variety of industries as a cost-effective, long-lasting lining material used to extend the operating life of equipment manufactured or lined with lower-wearing materials such as steel, cast iron, rubber, and polyurethane.

Cast basalt lined steel pipe, as both a wear-resistant and corrosion-resistant material, has proven effective over 30+ years of practical use.

It is also widely used in cement plants for components such as air separators, chain conveyors, hoppers, nozzles, ducts, chutes, and more.

Cast basalt lined steel pipe is a type of pipe wit...

Y-piece cast basalt pipe is a type of piping compo...

Heavy-duty steel bends with seamless cast basalt l...

Cast basalt lined steel tees deliver exceptional a...

Steel pipes lined with high-performance silicon ca...